Choosing the Right Finish for Your Project

Selecting between matte and glossy aluminum sublimation sheets can significantly impact your final product’s appearance and functionality. This guide explores the key differences, advantages, and ideal applications for each finish to help you make the best choice for your specific needs.

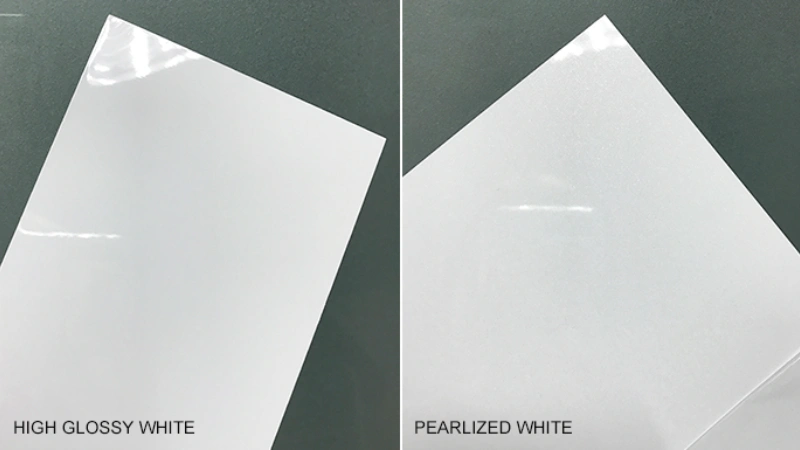

Key Differences Between Matte and Glossy Finishes

| Characteristic | Matte Finish | Glossy Finish | Significance |

|---|---|---|---|

| Surface Texture | Smooth, non-reflective | Smooth, reflective | Affects light interaction |

| Gloss Level | 10-20 GU | 80-100 GU | Determines shine intensity |

| Color Appearance | Softer, muted tones | Vibrant, saturated colors | Impacts visual impact |

| Fingerprint Resistance | Excellent | Poor | Affects maintenance needs |

| Scratch Visibility | Low | High | Influences durability perception |

Technical Specifications Comparison

| Parameter | Matte Sheets | Glossy Sheets | Measurement Standard |

|---|---|---|---|

| Surface Roughness | Ra 0.3-0.5μm | Ra 0.1-0.2μm | ISO 4287 |

| Light Reflectance | 20-30% | 80-90% | ASTM E1477 |

| Color Gamut | 90% Adobe RGB | 95% Adobe RGB | ISO 12640-2 |

| Sublimation Temperature | 190-200°C | 185-195°C | Manufacturer specs |

| Ink Absorption Time | 3-5 seconds | 1-2 seconds | Industry standard |

Application-Based Recommendations

Choose MATTE When:

- Artistic Photography: Portraits and fine art reproductions

- Office Environments: Professional signage and decor

- High-Traffic Areas: Where fingerprints and smudges are concerns

- Subtle Branding: Sophisticated, understated presentations

- Text-Heavy Designs: Better readability with reduced glare

Choose GLOSSY When:

- Product Photography: E-commerce and retail displays

- Vibrant Graphics: Maximum color impact needed

- Outdoor Signage: Enhanced weather resistance

- Food and Beverage: Appetite-appealing presentations

- Premium Products: Luxury appearance and perception

Performance Comparison Table

| Performance Aspect | Matte Finish | Glossy Finish | Winner |

|---|---|---|---|

| Color Vibrancy | 8/10 | 10/10 | Glossy |

| Scratch Resistance | 9/10 | 6/10 | Matte |

| Fingerprint Resistance | 10/10 | 4/10 | Matte |

| Light Diffusion | 10/10 | 3/10 | Matte |

| Durability | 9/10 | 7/10 | Matte |

| Visual Impact | 8/10 | 10/10 | Glossy |

Industry-Specific Recommendations

Photography & Art:

- Matte: Fine art prints, portrait photography, gallery exhibitions

- Glossy: Commercial photography, product shots, promotional materials

Retail & Signage:

- Matte: Office signage, directional signs, informational displays

- Glossy: Product displays, promotional signage, point-of-sale materials

Interior Design:

- Matte: Home decor, restaurant walls, hotel artwork

- Glossy: Feature walls, accent pieces, decorative elements

Industrial Applications:

- Matte: Control panels, equipment labels, safety signs

- Glossy: Branding panels, product identification, premium displays

Cost and Availability Comparison

| Factor | Matte Sheets | Glossy Sheets | Notes |

|---|---|---|---|

| Price per sheet | $8-12 | $7-10 | 1mm thickness, 1m² |

| Production Lead Time | 5-7 days | 3-5 days | Standard orders |

| Minimum Order Quantity | 25 sheets | 20 sheets | Most manufacturers |

| Custom Sizes Available | Yes | Yes | Additional cost may apply |

| Color Consistency | Excellent | Very Good | Batch to batch |

Environmental Considerations

| Factor | Matte Finish | Glossy Finish | Environmental Impact |

|---|---|---|---|

| Recyclability | Fully recyclable | Fully recyclable | Equal |

| Production Energy | Standard | Slightly higher | Glossy requires more processing |

| VOC Emissions | Low | Moderate | Glossy coatings may emit more VOCs |

| Longevity | 10-15 years | 8-12 years | Matte generally lasts longer |

| Maintenance Needs | Low | High | Affects cleaning chemical use |

Maintenance and Care Guide

Matte Finish Maintenance:

- Clean with microfiber cloth

- Use mild detergent if needed

- Avoid abrasive cleaners

- Dust regularly with soft brush

- No special storage requirements

Glossy Finish Maintenance:

- Requires frequent cleaning

- Use glass cleaner for best results

- Immediately remove fingerprints

- Store in protective sleeves

- Avoid rough handling

FAQ

Q: Can I achieve the same color vibrancy with matte as with glossy?

A: While matte offers excellent color reproduction, glossy typically provides 10-15% greater color saturation and vibrancy due to its reflective properties.

Q: Which finish is better for outdoor use?

A: Both work outdoors, but glossy offers better UV resistance and weather protection, while matte shows dirt and debris less noticeably.

Q: Do the printing settings differ between finishes?

A: Yes, glossy sheets typically require 5-10°C lower pressing temperature and 10-15 seconds less pressing time compared to matte sheets.

Q: Can I convert glossy sheets to matte?

A: No, the finish is permanently applied during manufacturing. However, matte laminate can be applied over glossy prints.

Q: Which finish is more popular for commercial use?

A: Glossy dominates retail and promotional applications (60%), while matte is preferred for architectural and professional settings (70%).

Conclusion: Making the Right Choice

Choose Matte If:

- You need reduced glare and reflections

- Fingerprint resistance is important

- You want a sophisticated, professional look

- The product will be handled frequently

- You prefer subtle, elegant presentations

Choose Glossy If:

- Maximum color impact is crucial

- You’re creating eye-catching displays

- The product will be viewed from distance

- You want a premium, high-end appearance

- Moisture resistance is needed

Consider Both When:

- Creating product lines with different price points

- Serving diverse client preferences

- Working with various lighting conditions

- Producing for multiple applications

- Budget allows for inventory variety

Leave a Reply

You must be logged in to post a comment.