Sublimating aluminum photo panels is one of the most popular ways to create durable and vivid photo products. Aluminum panels are strong, scratch-resistant, and deliver excellent image quality.

What Is Sublimation on Aluminum Photo Panels?

Sublimation is a heat transfer process where sublimation ink turns into gas and bonds with the polyester coating on aluminum panels. This method ensures the image is permanent, waterproof, and resistant to fading.

- Long-lasting colors

- Smooth, glossy, or matte finish

- Perfect for personal gifts and professional displays

Materials and Tools Needed

| Item | Specification | Notes |

|---|---|---|

| Aluminum Photo Panels | Sizes: A4 (210x297mm), A3 (297x420mm), 8×10 inch, 12×18 inch | Coated with polyester layer |

| Heat Press Machine | Temp: 180–200°C | Flat press recommended |

| Sublimation Paper | High-release type | For transferring images |

| Sublimation Ink | CMYK colors | Compatible with inkjet printers |

| Protective Gloves | Heat resistant | For safety when pressing |

Step-by-Step Guide: How to Sublimate Aluminum Photo Panels

1: Prepare Your Design

- Use graphic software (Photoshop, CorelDraw, etc.).

- Mirror the image before printing.

- Set high resolution (300 DPI) for sharp results.

2: Print the Design

- Print on sublimation paper with sublimation ink.

- Ensure correct printer settings (ICC profile if available).

3: Prepare the Aluminum Panel

- Peel protective film from the coated side.

- Clean the surface with a lint-free cloth.

- Place the sublimation paper face down on the panel.

4: Heat Press Settings

| Panel Thickness | Temperature | Time | Pressure |

|---|---|---|---|

| 0.5 mm | 185°C | 50 seconds | Medium |

| 1.0 mm | 190°C | 60 seconds | Medium-High |

| 1.5 mm | 195°C | 70 seconds | High |

5: Cooling and Finishing

- Remove paper carefully while hot.

- Place panel on a cool surface.

- Your sublimated photo panel is ready!

Applications of Aluminum Photo Panels

Aluminum sublimation panels are widely used in both personal and commercial projects:

- Home Decoration: Wall art, family portraits, and gallery displays.

- Photography: Professional photographers use them for exhibitions.

- Business Branding: Signage, office decoration, and nameplates.

- Gifts: Personalized photo gifts, awards, and souvenirs.

- Industrial Use: Informational plates, promotional displays.

Essential Supplies for Sublimating Aluminum Photo Panels

Before you begin creating your stunning metal prints, gather all the necessary tools and materials. Having everything ready will make the process smoother and more efficient.

| Item | Description | Why You Need It |

|---|---|---|

| Sublimation Printer | A printer specifically designed for sublimation, using sublimation inks. | Regular ink won’t work; sublimation ink is key to the transfer. |

| Sublimation Ink | Specialized dyes that turn into gas under heat and pressure. | Essential for the sublimation process. |

| Sublimation Paper | Coated paper designed to release sublimation ink efficiently onto the substrate. | Standard paper holds too much ink, resulting in dull transfers. |

| Aluminum Photo Panels | The actual aluminum blanks with a special polymer coating on the surface. | This coating is what the sublimation ink bonds to. |

| Heat Press | A machine that applies precise heat and pressure for a specific time. | Crucial for the dye to sublimate and transfer permanently. |

| Heat-Resistant Tape | Tape that can withstand high temperatures without melting or leaving residue. | Secures your design to the panel, preventing “ghosting.” |

| Protective Paper | Butcher paper, silicone-coated paper, or Teflon sheets. | Protects your heat press platens from ink bleed-through. |

| Heat-Resistant Gloves | Protects your hands when handling hot panels. | Panels will be extremely hot after pressing. |

| Lint-Free Cloth | For cleaning the panel surface. | Ensures a pristine, dust-free surface for transfer. |

Advantages of Sublimating Aluminum Photo Panels

- High-definition printing quality

- Resistant to scratches and water

- Long lifespan compared to paper or canvas

- Multiple size options available

- Lightweight and easy to hang

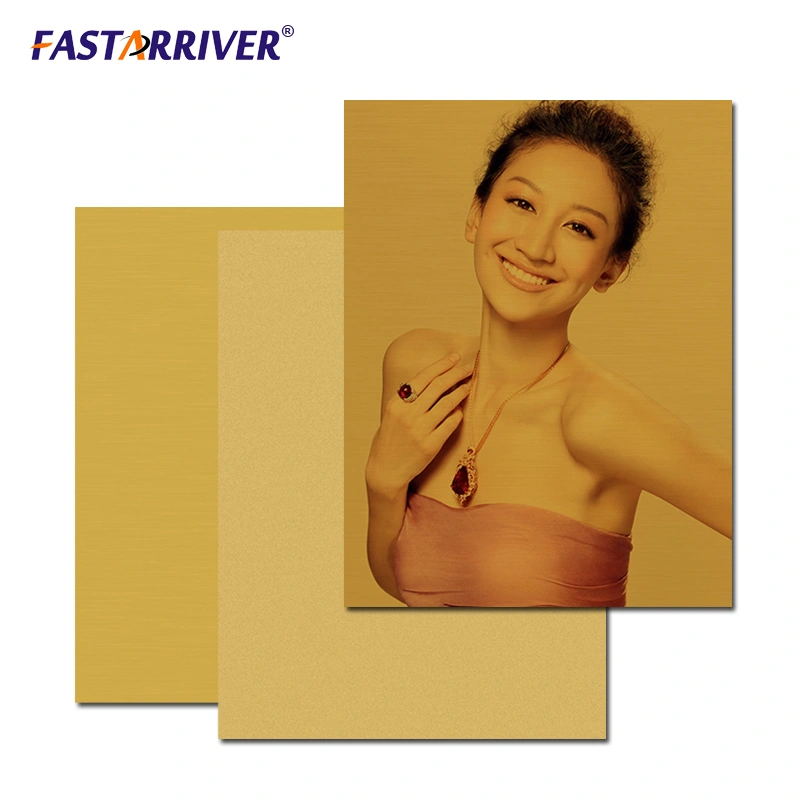

Types and Sizes of Aluminum Photo Panels

| Type | Finish | Common Sizes (mm/inch) | Thickness |

|---|---|---|---|

| Glossy White | Shiny, reflective | A4, A3, 8×10, 12×18 | 0.5–1.5 mm |

| Matte White | Smooth, non-glare | A4, A3, 16×20 | 1.0–1.5 mm |

| Brushed Silver | Metallic look | 200×300, 300×400 | 0.5–1.0 mm |

| Glossy Gold | Decorative | Custom sizes | 0.5–1.0 mm |

Tips for Best Results

- Always test a small panel before mass production.

- Store sublimation paper in a dry place.

- Adjust heat press settings depending on panel thickness.

- Use heat-resistant tape to prevent ghosting.

Troubleshooting Common Sublimation Issues

Even with the best preparation, issues can arise. Here are quick fixes for common problems when you sublimate aluminum photo panels:

Yellowing/Discoloration: Can be caused by too much heat or too long of a press time.

Fading/Dull Colors: Usually too little heat, pressure, or time. Also check if your printer settings are correct.

Ghosting (Blurry Double Image): Caused by the paper shifting during pressing or removal. Use more heat-resistant tape, or cool the panel slightly before peeling.

Uneven Transfer: Often due to uneven pressure in the heat press, cold spots, or not enough pressure.

White Spots/Specks: Indicates dust, lint, or fingerprints on the panel before pressing. Clean meticulously!

FAQ

Q: Can you sublimate both sides?

A: Yes, with double-sided coated panels

Q: How long do sublimated images last?

A: 50+ years indoors with proper care

Q: What software is best?

A: Adobe Photoshop, Illustrator, or specialized RIP software

Q: Can you sublimate colored aluminum?

A: Yes, but colors will mix with panel color

Q: How to prevent scratching?

A: Use protective sprays or laminates

Leave a Reply

You must be logged in to post a comment.