When you are looking for aluminum sublimation metal sheet suppliers, it is important to understand the product, its specifications, and where it can be applied. This article will guide you through the key information about aluminum sublimation metal sheets, their classifications, thickness options, alloys, and common uses.

Key Specification

| Item | Details |

|---|---|

| Classification | Coated aluminum sublimation sheet (blank panel) |

| Thickness | 0.45 mm – 2.0 mm standard; custom gauges on request |

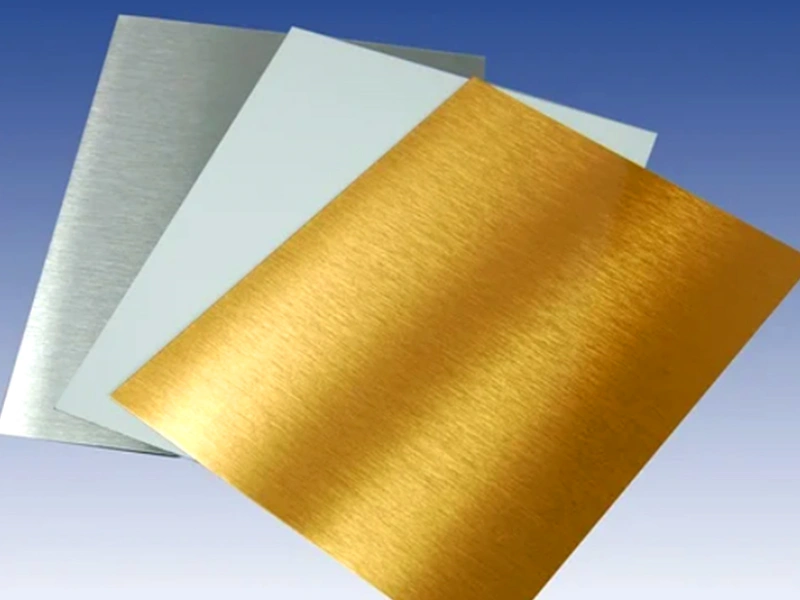

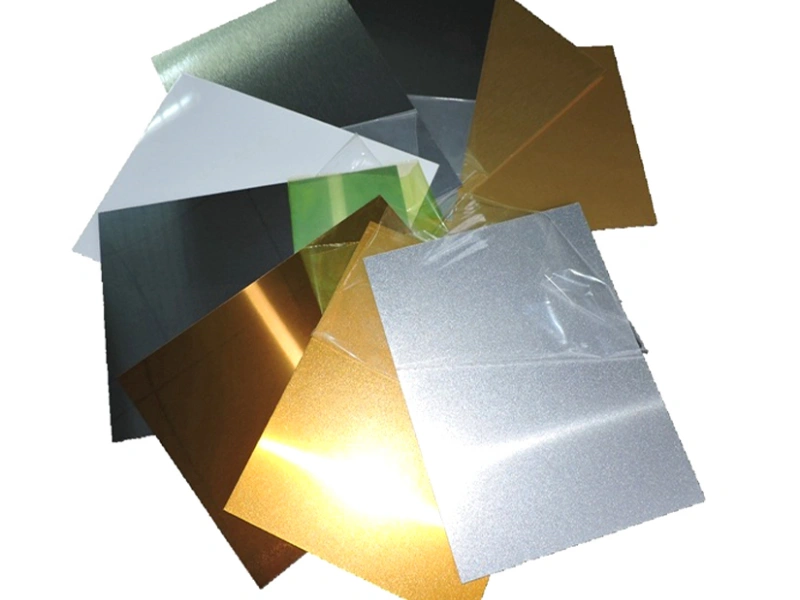

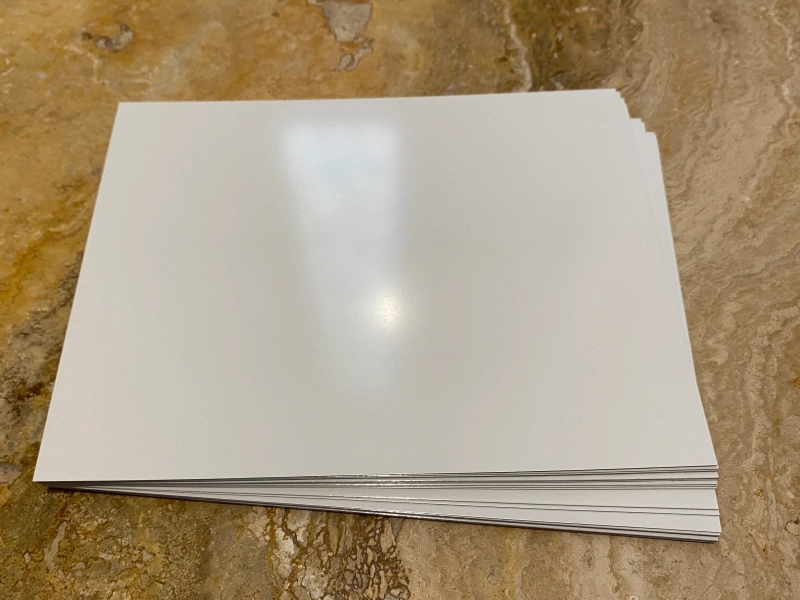

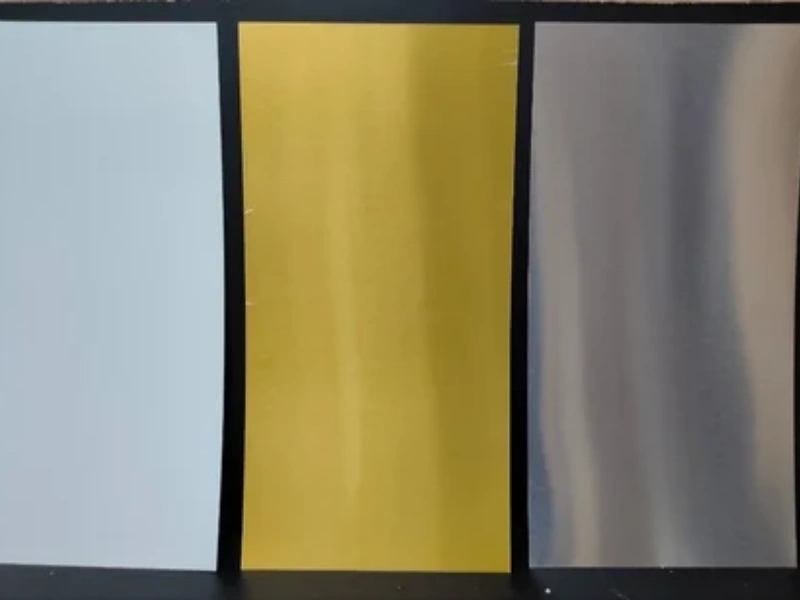

| Sub‑label (Finish) | White gloss, white matte, brushed silver, brushed gold, clear |

| Alloy | 1050 / 1060 / 3003 (superior flatness & heat transfer) |

| Standard Sizes | 605 × 405 mm, 610 × 305 mm, 1200 × 600 mm, bespoke cuts |

| Protective Film | BOTH sides PE film to prevent scratches |

Need a different alloy, finish, or cut? Ask for free samples within 24 h.

What is Aluminum Sublimation Metal Sheet?

Aluminum sublimation metal sheets are specially designed aluminum panels that can transfer high-quality images through sublimation printing. This process allows detailed and vibrant designs to be permanently embedded into the metal surface.

These sheets are popular in many industries because they are strong, lightweight, and resistant to corrosion. Many aluminum sublimation metal sheet suppliers offer a wide range of options to fit different needs.

Classification of Aluminum Sublimation Metal Sheets

Aluminum sublimation sheets can be classified based on their surface finish and core structure. Suppliers typically provide:

- Solid Aluminum Sheets: A single layer of aluminum that is perfect for high-quality sublimation printing.

- Aluminum Composite Panels (ACP): These have a core material (often polyethylene) between two aluminum sheets, offering extra strength and durability.

These classifications help businesses choose the right product based on strength, weight, and print quality requirements.

Thickness Options

Thickness plays an important role in the performance of aluminum sublimation sheets. Common thicknesses include:

- 0.2 mm to 0.5 mm for thin, flexible sheets ideal for light-duty applications.

- 0.5 mm to 1.0 mm for more durable sheets in moderate impact environments.

- More than 1.0 mm for heavy-duty applications requiring extra strength.

When looking for aluminum sublimation metal sheet suppliers, always specify the thickness you need. The right thickness ensures the final product meets your quality standards and usage requirements.

Alloy Types

The alloy used in aluminum sublimation sheets affects its strength, flexibility, and corrosion resistance. Popular alloys include:

- 1100 Alloy: Pure aluminum with excellent corrosion resistance, suitable for indoor and outdoor use.

- 3003 Alloy: Stronger than 1100, with good corrosion resistance and ideal for general use.

- 5005 Alloy: Offers the best corrosion resistance and surface finish, highly recommended for high-quality sublimation printing.

Choosing the correct alloy with your supplier will enhance the durability and appearance of your aluminum sublimation sheets.

Applications of Aluminum Sublimation Metal Sheets

Aluminum sublimation sheets are versatile and used in many fields. Common applications include:

- Signage: Outdoor and indoor signs with vibrant, weather-resistant prints.

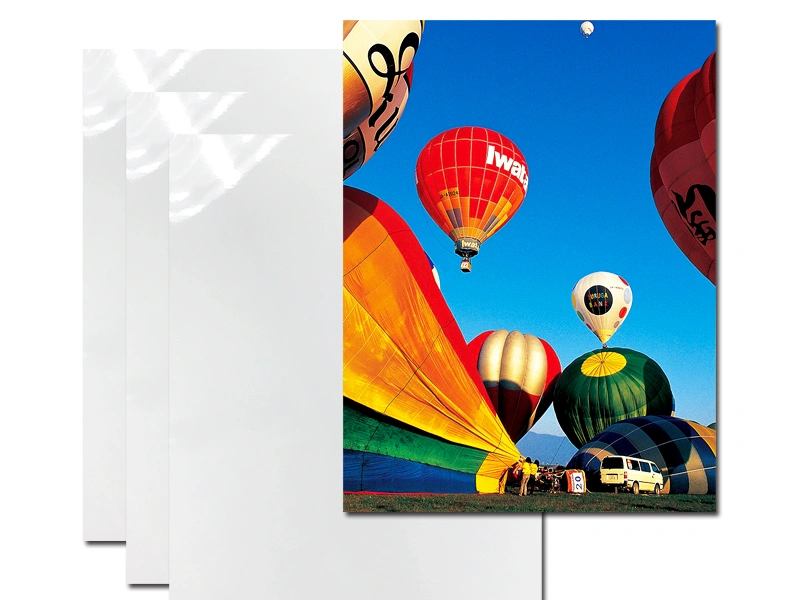

- Photo panels: High-quality photo displays in homes, offices, and galleries.

- Decorative panels: Wall art, interior decorations, and architectural elements.

- Nameplates and labels: Durable metal nameplates with sharp images.

- Promotional products: Custom printed giveaways such as keychains or plaques.

- Awards and trophies: Personalized metal awards with colorful graphics.

Using aluminum sublimation sheets ensures vivid prints with long-lasting durability in all these applications.

Why Choose Reliable Aluminum Sublimation Metal Sheet Suppliers?

Selecting the right supplier is important to get the best quality sheets at competitive prices. Reliable suppliers offer:

- Consistent product quality with accurate thickness and alloy specifications.

- Wide range of sheet classifications and customization options.

- Excellent customer service and timely delivery.

- Technical support for choosing the right product for your needs.

Partnering with a trusted aluminum sublimation metal sheet supplier helps you maintain your product quality and customer satisfaction.

Frequently Asked Questions

Q1. What is the recommended heat‑press setting?

A. 190‑200 °C for 60 seconds at medium pressure; adjust slightly for darker designs.

Q2. Can I cut sheets after sublimation?

Yes—use a guillotine, laser, or CNC router. Seal cut edges with clear coat if outdoor durability is critical.

Q3. Do you offer double‑sided coating?

Absolutely. Dual‑coat blanks are available for directional signs and two‑sided photo ornaments.

Q4. Are the sheets food‑safe?

The polyester coating is BPA‑free and compliant with EU RoHS directives, but not intended for direct food contact.

Leave a Reply

You must be logged in to post a comment.