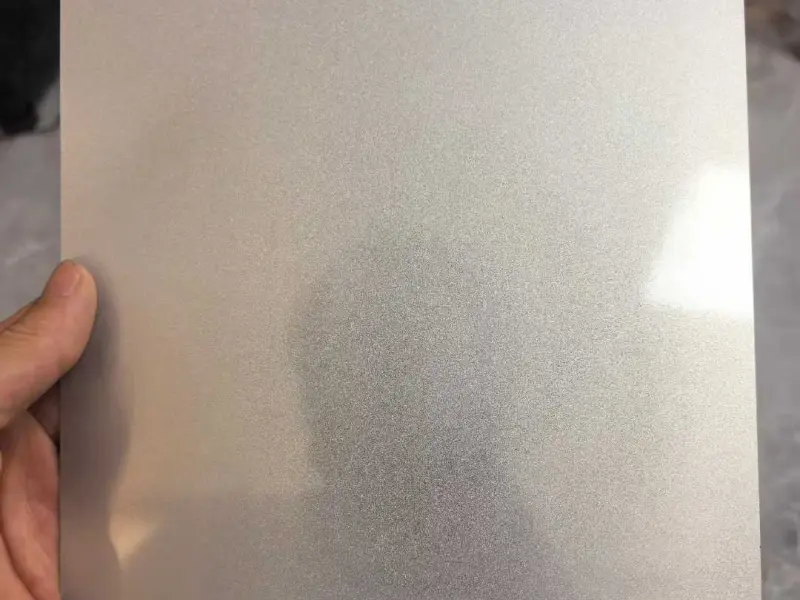

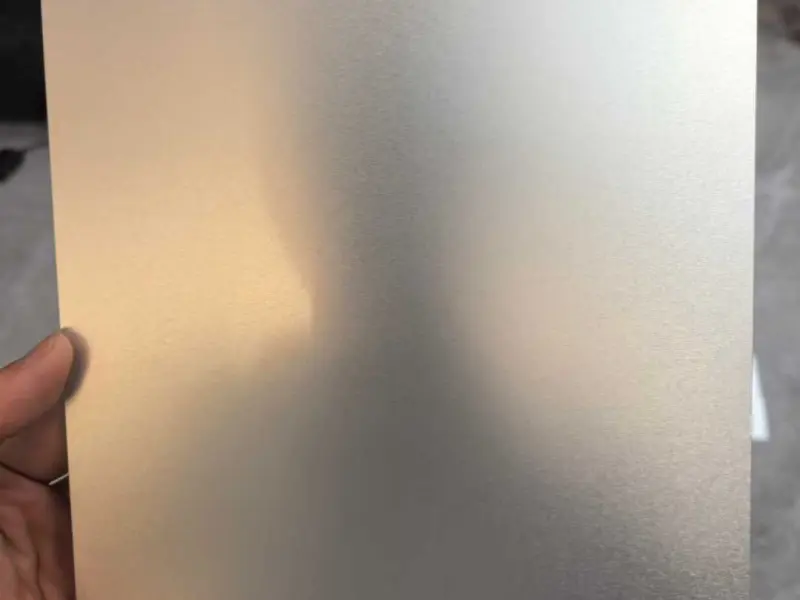

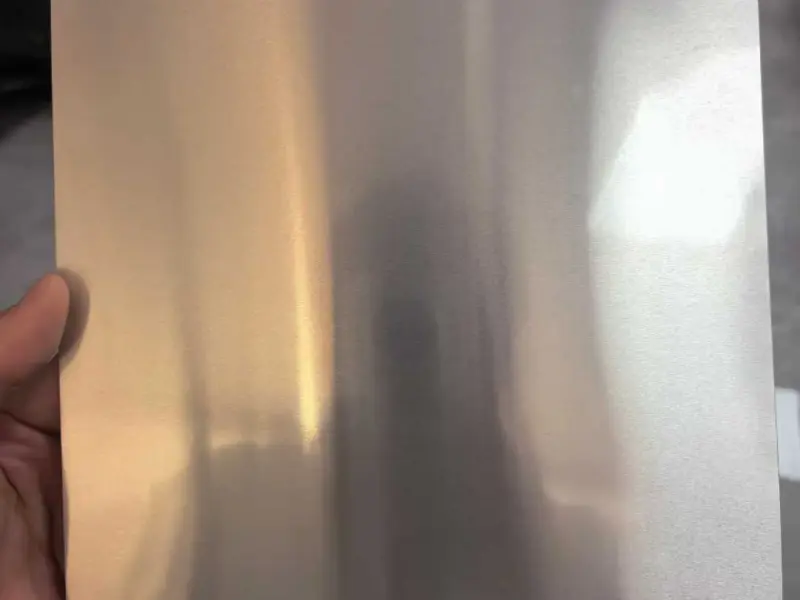

Aluminum for sublimation is specially coated metal designed for transferring images, text, or graphics with sublimation printing. The process ensures vivid, durable, and scratch-resistant results, making it perfect for gifts, signage, awards, and decorative items.

How to Use Aluminum for Sublimation

Using sublimation aluminum is straightforward. Follow these simple steps:

- Select the right aluminum sheet

- Choose size and thickness based on your project (0.5–1.0 mm for most photo panels).

- Check alloy type: 1060 is smooth for photos, 5052 for durability.

- Prepare the design

- Use sublimation software to mirror the image.

- Print using sublimation ink on transfer paper.

- Apply heat and pressure StepSettingsTemperature180–200°CTime45–60 secondsPressureMedium, even pressureProtective FilmKeep on during transfer

- Cooling and finishing

- Let the aluminum cool completely.

- Peel off protective film carefully.

- Check the final image for clarity and color accuracy.

Why Choose Our Aluminum for Sublimation

- High-Quality Coating

- Smooth, uniform coating ensures sharp and vivid images.

- Durable Material

- Our aluminum alloys resist scratches, fading, and corrosion.

- Wide Range of Sizes and Thicknesses

- Flexible options for small gifts or large signage projects.

- Factory Direct Supply

- No middlemen, lower cost, and consistent availability.

- Safe Packaging

- Each sheet is covered with protective film and packed in sturdy cartons to avoid damage during shipping.

Applications – What Customers Commonly Do

- Photo Panels & Wall Art – Family portraits, gallery art, decorative prints.

- Awards & Recognition – School plaques, corporate awards, event trophies.

- Signage – Office nameplates, hotel signs, direction markers.

- Personalized Gifts – Customized keychains, plaques, or decorative items.

1. Can I use sublimation aluminum outdoors?

Many customers ask if sublimation aluminum is suitable for outdoor use. Our 3003 and 5052 aluminum alloys are corrosion-resistant and durable, making them perfect for outdoor signage, plaques, or decorative panels. Using the correct alloy ensures your prints stay vibrant even under sun or rain exposure.

2. What thickness should I choose for small items?

For lightweight projects like keychains, small plaques, or mini photo panels, 0.3–0.5 mm thickness is ideal. Thinner sheets are easier to handle, bend, and transfer images onto. For medium or large plaques, we recommend 0.7–1.0 mm to ensure rigidity and durability.

3. How do I clean the aluminum sheet after printing?

Customers often wonder how to maintain the printed aluminum. Use a soft, dry, or slightly damp cloth to remove dust or fingerprints. Avoid harsh chemicals or abrasive tools that could damage the sublimated surface. Proper cleaning helps maintain the print’s clarity and color vibrancy.

4. Can I cut or shape the aluminum before sublimation?

Yes, aluminum can be cut, drilled, or shaped before sublimation. However, edges should be smooth to avoid damaging the coating during the printing process. Testing a small piece first is recommended if you are doing custom shapes or creative designs.

5. Do you provide custom sizes or shapes?

Many customers require custom dimensions for specific projects. We offer standard sizes like A4, A3, and 30×40 cm, as well as custom shapes such as round, oval, heart, or any personalized size. This flexibility allows businesses and creative individuals to produce unique, tailored products.

6. What type of printer and ink should I use?

Sublimation aluminum works best with sublimation printers and sublimation inks (Epson, Sawgrass, etc.). Using proper heat press settings ensures that the design fully transfers and bonds to the coated surface, producing long-lasting, vivid images.

7. How do I handle the aluminum sheet during printing?

It’s common for customers to worry about scratches or fingerprints. Keep the protective film on until after printing. Handle the sheet by edges, avoid touching the coated surface, and let it cool completely before removing the film.

Caring for Your Sublimation Aluminum Prints

Maintaining the beauty of your sublimation aluminum prints is incredibly easy. Their inherent durability means they don’t require much special care.

Display: While UV resistant, prolonged direct sunlight can eventually cause some fading. For maximum longevity, display prints out of direct, intense sunlight.

Cleaning: Use a soft, lint-free cloth (like a microfiber cloth) and a mild glass cleaner or just water. Gently wipe the surface.

Avoid: Do not use abrasive cleaners, harsh chemicals, or scouring pads, as these can damage the polymer coating.

Leave a Reply

You must be logged in to post a comment.