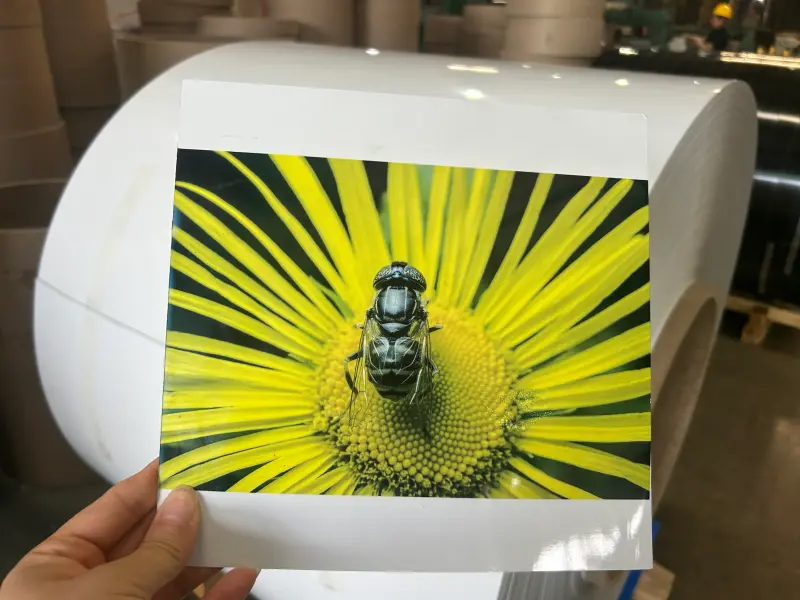

Sublimation printing on aluminum sheet is a popular method for creating high-quality, long-lasting images on metal. This process is widely used for photo panels, signage, decorative artwork, and industrial nameplates. Compared with paper or plastic, aluminum offers better durability, color brightness, and weather resistance.

Why Use Aluminum Sheets for Sublimation Printing?

Aluminum is one of the best materials for sublimation printing due to its stability and surface performance.

Advantages of Aluminum Sublimation Sheets

| Feature | Benefit |

|---|---|

| Rigid material | No warping |

| Metal surface | Premium appearance |

| Special coating | Strong ink adhesion |

| Lightweight | Easy handling |

| Corrosion resistant | Long service life |

How Sublimation Printing on Aluminum Works

The process is simple but precise.

Basic Sublimation Process

- Print image with sublimation ink

- Place transfer paper on aluminum sheet

- Apply heat and pressure

- Ink penetrates the coating

- Image becomes permanent

Typical Sublimation Settings

| Item | Range |

|---|---|

| Temperature | 180–200°C (356–392°F) |

| Time | 45–90 seconds |

| Pressure | Medium |

| Cooling | Natural air cooling |

Types of Aluminum Sheets for Sublimation Printing

Not all aluminum sheets are suitable for sublimation. A polyester-coated surface is required.

Common Sublimation Aluminum Sheet Types

| Type | Surface | Use |

|---|---|---|

| Glossy white aluminum | High gloss | Photo printing |

| Matte white aluminum | Low glare | Signage |

| Satin aluminum | Semi-matte | Decorative panels |

| Brushed aluminum | Textured | Modern design |

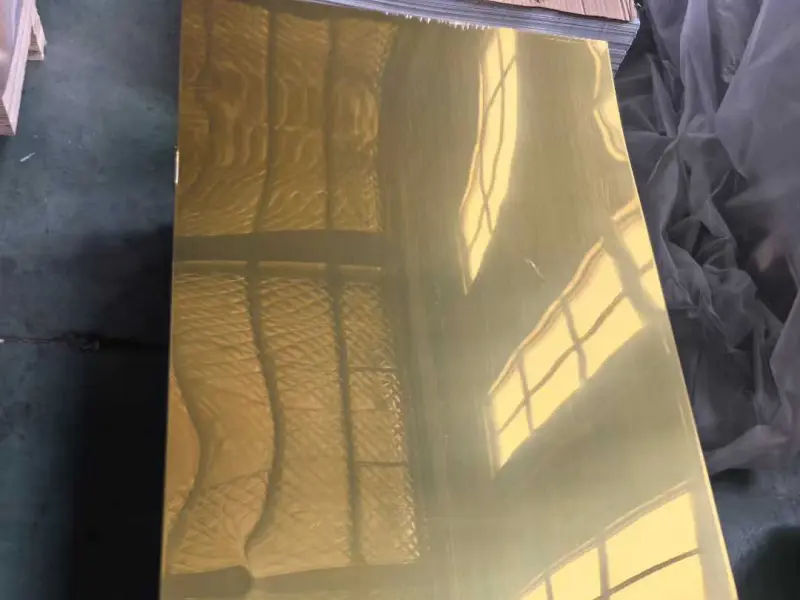

| Mirror aluminum | Reflective | Premium display |

Glossy vs Matte Sublimation Aluminum Sheets

Surface Comparison

| Feature | Glossy | Matte |

|---|---|---|

| Color brightness | Very high | Moderate |

| Reflection | Strong | Low |

| Fingerprints | Visible | Minimal |

| Best for | Photos | Signs & text |

Aluminum Alloys Used for Sublimation Sheets

Most sublimation aluminum sheets use pure or low-alloy aluminum for flatness and coating quality.

Common Aluminum Alloys

| Alloy | Temper | Characteristics |

|---|---|---|

| 1050 | H14 | Excellent coating |

| 1060 | H14 | High purity |

| 3003 | H14 | Good strength |

| 3105 | H14 | Painted products |

Standard Thickness Options

Thickness affects rigidity and application.

Typical Thickness Range

| Thickness (mm) | Thickness (inch) | Application |

|---|---|---|

| 0.5 | 0.020″ | Photo panels |

| 0.8 | 0.032″ | Wall signs |

| 1.0 | 0.040″ | Outdoor signs |

| 1.2 | 0.047″ | Displays |

| 1.6 | 0.063″ | Industrial use |

Popular Sizes for Sublimation Aluminum Sheets

Standard Sheet Sizes

| Size | Common Use |

|---|---|

| A4 (210×297 mm) | Photo printing |

| A3 (297×420 mm) | Artwork |

| A2 (420×594 mm) | Sign panels |

| 12″×18″ | Custom photos |

| 24″×36″ | Large signage |

Custom sizes are also available for bulk orders and B2B projects.

Applications of Sublimation Printing on Aluminum Sheet

Sublimated aluminum sheets are used across many industries.

Main Applications

- Photo panels

- Advertising signs

- Interior decoration

- Commercial displays

- Personalized gifts

Industry-Specific Applications

Photography & Art

- Photo wall panels

- Gallery artwork

- Home decoration

Advertising & Retail

- Store signage

- Promotional boards

- Brand displays

Industrial Use

- Nameplates

- Control panels

- Equipment labels

Personalized Products

- Custom gifts

- Awards and plaques

- Memorial panels

Indoor vs Outdoor Performance

| Environment | Performance |

|---|---|

| Indoor use | Excellent |

| Outdoor use | UV resistant |

| Humid areas | Corrosion resistant |

| High temperature | Stable |

Sublimation aluminum sheets are ideal for both indoor and outdoor applications when properly coated.

How to Maintain Sublimated Aluminum Sheets

Maintenance is simple and cost-effective.

Care Tips

- Clean with soft cloth

- Use mild detergent

- Avoid abrasive tools

- Do not use strong acids

Cost Factors of Sublimation Aluminum Sheets

The price depends on several factors.

Price Influencing Factors

| Factor | Impact |

|---|---|

| Thickness | Higher thickness = higher cost |

| Coating type | Glossy may cost more |

| Size | Larger size = higher price |

| Quantity | Bulk orders reduce cost |

Why Choose Sublimation Printing on Aluminum Sheet?

Compared with other printing methods, sublimation offers long-term value.

Key Reasons

- Permanent image quality

- High-definition printing

- Professional metal finish

- Long lifespan

- Suitable for mass production

What Is Sublimation Printing on Aluminum Sheet?

Sublimation printing on aluminum sheet is a heat transfer process. Special sublimation ink is printed onto transfer paper. Under high temperature and pressure, the ink turns into gas and bonds with the coated aluminum surface.

Key Features

- High-resolution image quality

- Permanent image bonding

- Scratch-resistant surface

- Fade-resistant colors

- Smooth and professional finish

Sublimation Printing on Aluminum Sheet

Sublimation printing on aluminum sheet is a reliable and modern solution for high-quality image printing. With various surface finishes, sizes, and thickness options, it meets the needs of photographers, advertisers, and industrial users.

Summary

- High-resolution image output

- Multiple surface options

- Durable and fade-resistant

- Wide application range

- Cost-effective for bulk orders

Leave a Reply

You must be logged in to post a comment.