Learning how to make a sublimation metal sheet gives you complete control over quality, coating, and size.

By following these simple steps — cleaning, coating, curing, and cutting — you can create professional-grade sublimation blanks ready for heat transfer printing.

Whether you’re a DIY crafter, photographer, or printing business, making your own sublimation aluminum sheets ensures high quality and flexibility for any project.

What Is a Sublimation Metal Sheet?

A sublimation metal sheet is a coated aluminum panel designed to hold high-quality images through a heat transfer process.

Unlike normal metal plates, sublimation sheets have a special polymer coating that absorbs sublimation ink when heated.

They are widely used for:

- Photo printing

- Wall decor

- Nameplates and signs

- Custom gifts and awards

Materials Needed to Make a Sublimation Metal Sheet

Before starting the process, prepare the right materials and tools.

| Material / Equipment | Purpose |

|---|---|

| Aluminum Sheet (1050 / 1060 / 5052) | Base metal |

| Sublimation Coating Liquid | Allows ink absorption |

| Spray Gun or Roller | To apply the coating |

| Oven or Heat Press | For curing the coating |

| Protective Gloves & Mask | Safety during coating |

| Cleaning Solution | Removes oil and dust |

Step-by-Step: How to Make a Sublimation Metal Sheet

1. Choose the Right Aluminum Base

Select a flat, smooth aluminum sheet.

Common choices include:

- 1050 aluminum (pure, easy to coat)

- 5052 aluminum (stronger and more durable)

- Thickness: 0.3mm to 1.2mm

| Alloy Type | Strength | Surface Quality | Common Use |

|---|---|---|---|

| 1050 | Soft | Excellent | Photo panels |

| 1060 | Medium | Smooth | Signboards |

| 5052 | Hard | Good | Outdoor displays |

2. Clean the Surface Thoroughly

Use alcohol or acetone to remove any:

- Oil

- Dust

- Fingerprints

A clean surface ensures better adhesion of the coating and avoids print defects.

3. Apply the Sublimation Coating

The coating forms the absorbent layer that captures sublimation ink.

Steps:

- Shake the sublimation coating liquid well.

- Spray evenly over the aluminum surface using a spray gun.

- Avoid dripping or thick spots.

- Let it air-dry for 10–15 minutes.

| Coating Type | Finish | Use |

|---|---|---|

| White Glossy | Shiny surface | Photo printing |

| Matte White | Soft reflection | Art panels |

| Clear Gloss | Metal look | Decorative pieces |

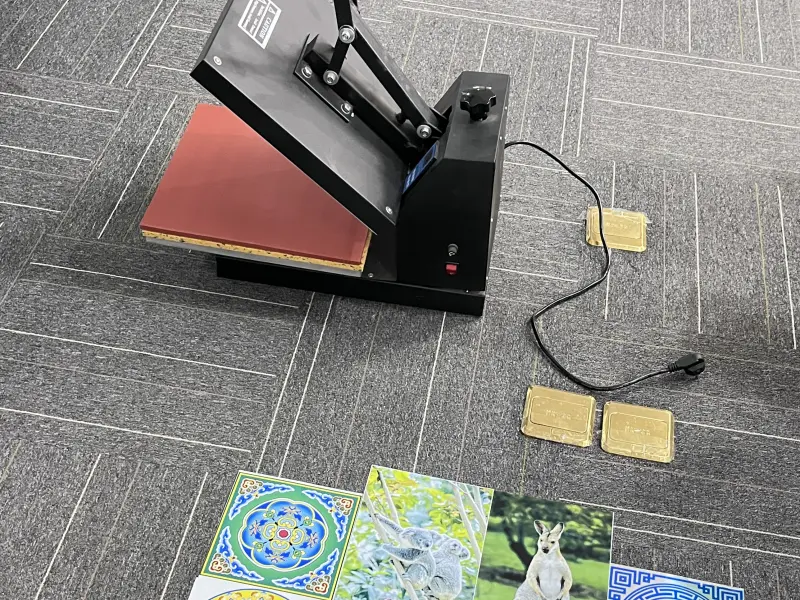

4. Cure the Coating

After applying the coating, the sheet must be cured to bond the layer to the aluminum.

You can use:

- Oven: Bake at 180°C (356°F) for 20–25 minutes

- Heat Press: Press at 190°C (374°F) for 8–10 minutes with light pressure

After curing, let the sheets cool naturally.

5. Test the Surface

Once cooled, check for:

- Smooth finish

- No dust or bubbles

- Even coating

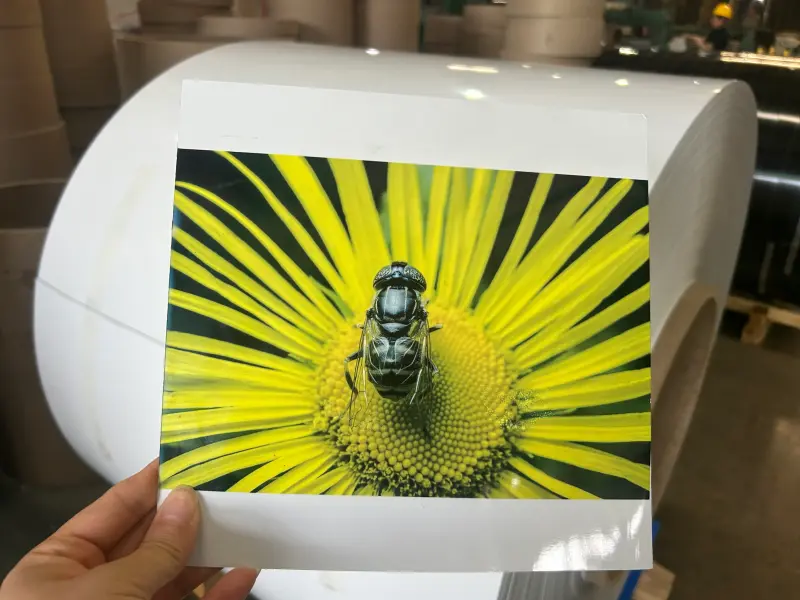

A well-coated surface will feel glossy and uniform. You can perform a quick heat test by printing a small image.

Optional: Pre-cutting and Corner Shaping

After coating, the sheets can be cut into standard sizes for easy use.

| Size (inch) | Size (mm) | Typical Use |

|---|---|---|

| A4 | 210×297 | Desktop photos, DIY prints |

| A3 | 297×420 | Wall decor |

| 5×7 / 8×10 | – | Photo gifts |

| 12×24 / 24×36 | – | Large displays |

| Round (Ø2–8″) | – | Coasters, ornaments |

You can also add rounded corners or protective film for safety and shine.

6. Print on the Finished Metal Sheet

Now the sublimation metal sheet is ready to use.

Steps:

- Print your design on sublimation paper using sublimation ink.

- Place the printed paper face-down on the coated metal sheet.

- Press at 190–200°C (374–392°F) for 60–90 seconds.

- Peel off the paper carefully — the image will appear bright and permanent.

Common Problems and Solutions

| Problem | Cause | Solution |

|---|---|---|

| Blurry print | Low temperature | Increase heat to 190–200°C |

| Uneven color | Uneven coating | Spray evenly |

| Yellow spots | Overheating | Reduce press time |

| Ink not absorbed | Wrong surface | Ensure polymer coating applied |

Advantages of Making Your Own Sublimation Metal Sheets

- Cost-Effective: Save money on bulk production.

- Customizable: Control size, shape, and coating type.

- Business Opportunity: Ideal for small print shops or craft sellers.

- High Profit Margin: Sell personalized panels or blanks.

Applications of Sublimation Metal Sheets

Sublimation metal sheets can be used in many creative and industrial ways:

Personal Use

- Family portraits

- Custom artwork

- Wedding and baby photos

Commercial Use

- Name badges and tags

- Business signage

- Promotional displays

Industrial Use

- Machine labels

- Control panels

- Equipment plates

Technical Data Summary

| Property | Specification |

|---|---|

| Material | Aluminum alloy (1050 / 1060 / 5052) |

| Thickness | 0.3–1.2 mm |

| Coating | Sublimation polymer layer |

| Heat Transfer Temp. | 190–200°C |

| Time Range | 60–90 seconds |

| Finish Options | Glossy, Matte, Brushed |

| Available Sizes | A4, A3, Custom |

Leave a Reply

You must be logged in to post a comment.