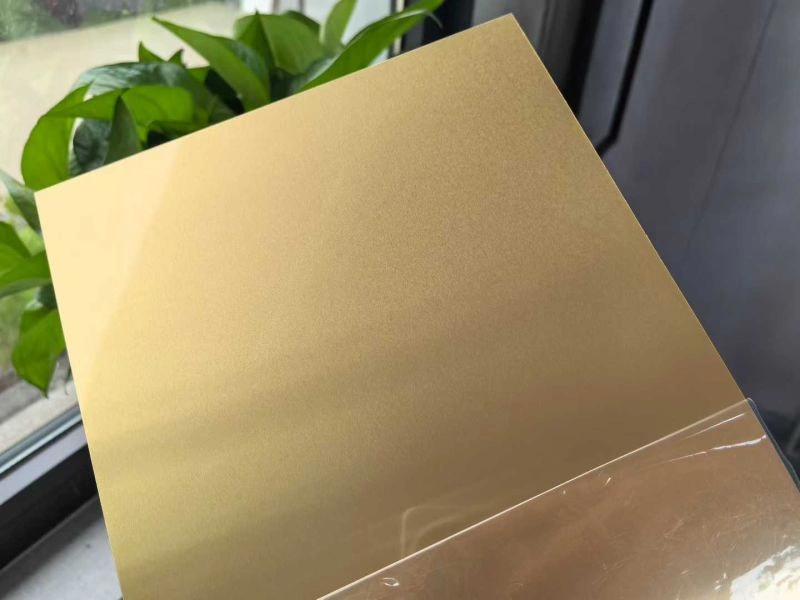

Sublimation on Metal Temperature is a heat transfer printing process where special sublimation ink turns into gas and bonds with the polymer coating on a metal sheet. This method produces vivid, durable, and fade-resistant images on aluminum and other coated metals.

Sublimation metal products include:

- Photo panels

- Nameplates

- Trophies

- Signboards

- Custom metal gifts

How to Sublimate on Metal

To get the best print results, follow these simple steps:

| Step | Description | Recommended Setting |

|---|---|---|

| 1. Prepare the metal | Use a clean, coated metal sheet for sublimation | Surface should be free of dust or oil |

| 2. Print the image | Print your design using sublimation ink on transfer paper | Mirror image required |

| 3. Align the print | Place printed paper on top of the metal face-down | Fix with heat tape |

| 4. Press the metal | Use a flat heat press machine | 190°C – 200°C (375°F – 400°F) |

| 5. Cool and remove | Allow the metal to cool before peeling | Prevents ghosting or smudging |

Sublimation Heat Press Temperature for Polyester and Metal

The heat press temperature and time vary depending on the substrate type and coating thickness.

| Material | Temperature (°C) | Time (Seconds) | Pressure |

|---|---|---|---|

| Aluminum sheet (white coating) | 190 – 200 | 50 – 60 | Medium |

| Silver glossy aluminum | 190 | 45 – 55 | Medium |

| Polyester fabric | 200 | 35 – 45 | Light |

| Steel plate (polymer-coated) | 195 | 60 – 70 | Medium-high |

Tip: Always preheat the metal for 5 seconds to remove moisture and prevent blurring.

Sublimation Heat Press Settings

To achieve sharp, color-rich prints:

- Temperature: 190°C – 200°C

- Time: 50 – 60 seconds

- Pressure: Medium (avoid excessive force)

- Cooling: Let the metal cool naturally on a flat surface

Common issues:

- Faded colors → too low temperature

- Yellow tint → too high temperature

- Blurry edges → overpressing or misalignment

Can You Sublimation Print on Metal?

Yes. You can sublimate on specially coated aluminum sheets or metal panels that have a polymer coating.

Bare metal won’t absorb sublimation ink because it lacks a coating.

Suitable metals for sublimation:

- Aluminum

- Stainless steel (with coating)

- Chromaluxe panels

How Long to Press Metal Sublimation Signs?

Most metal sublimation signs require 50 to 60 seconds at 190°C to 200°C with medium pressure.

| Metal Type | Press Time (sec) | Temperature (°C) |

|---|---|---|

| White Aluminum | 55 | 195 |

| Silver Aluminum | 50 | 190 |

| Gold Aluminum | 60 | 200 |

Avoid overpressing — too much heat can cause ink bleeding or color fading.

Is an Iron Hot Enough for Sublimation?

No. A household iron cannot reach or maintain the precise temperature (190°C–200°C) required for sublimation.

Use a heat press machine instead for:

- Accurate temperature control

- Even pressure distribution

- Consistent image quality

How Long to Sublimate on 50/50 Fabric?

For 50/50 cotton-polyester fabric, sublimation is possible but colors appear lighter since only the polyester fibers hold the ink.

| Fabric Type | Temperature (°C) | Time (sec) | Result |

|---|---|---|---|

| 100% Polyester | 200 | 40 | Bright colors |

| 50/50 Cotton-Poly | 200 | 45 | Softer, pastel effect |

| 100% Cotton | — | — | Not suitable for sublimation |

Applications of Metal Sublimation Printing

Metal sublimation printing is ideal for both personal and commercial uses:

- Home decoration: Custom photo panels, wall art

- Advertising: Nameplates, door signs, displays

- Industrial use: Control panels, product labels

- Promotional items: Awards, trophies, souvenirs

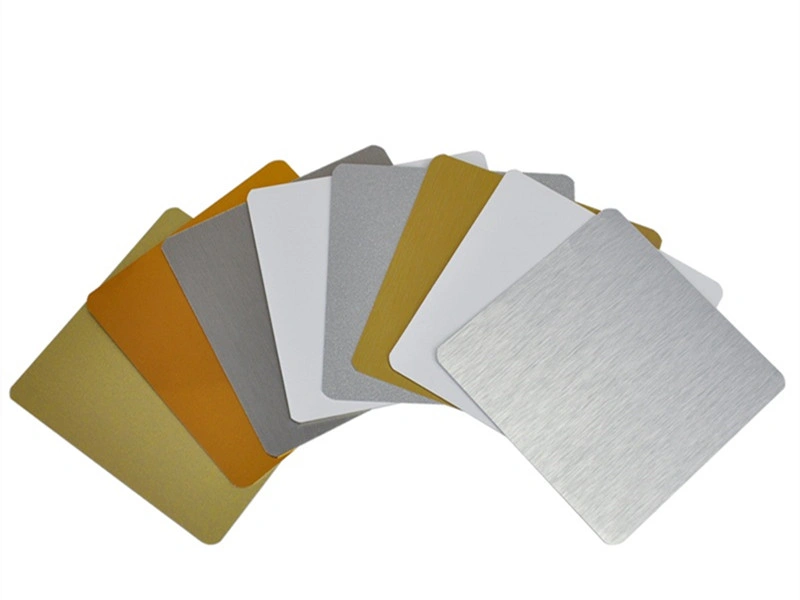

Common Sublimation Metal Sheet Sizes

| Size (inch) | Thickness (mm) | Finish Options |

|---|---|---|

| 8×10 | 0.5 | Glossy, Matte |

| 12×18 | 0.8 | White, Silver |

| 16×20 | 1.0 | Brushed, Gold |

| Custom | 0.5–1.2 | UV-protected coating |

Sublimation on Metal Temperature

Understanding the correct sublimation on metal temperature is essential for perfect results. Maintain a consistent 190°C–200°C with 50–60 seconds press time to get vivid and durable prints.

Whether you’re printing photo panels, signs, or metal tags, correct heat settings will ensure sharp, colorful, and long-lasting images on your sublimation metal sheets.

Troubleshooting Temperature Issues

Common problems and solutions with sublimation on metal temperature:

Problem-Solution Table:

| Problem | Cause | Solution |

|---|---|---|

| Faded Colors | Temperature too low | Increase 5-10°F |

| Brown Spots | Temperature too high | Decrease 5-10°F |

| Blurry Image | Uneven pressure | Adjust pressure settings |

| Ink Transfer | Wrong time setting | Adjust pressing time |

Best Practices for Consistent Results

Achieve perfect results with these sublimation heat press settings tips:

- Pre-test Settings: Always test on small pieces first

- Use Timer: Precise timing is crucial

- Check Temperature: Verify with infrared thermometer

- Even Pressure: Ensure consistent pressure across surface

- Record Settings: Keep notes of successful combinations

Safety Considerations

Working with sublimation on metal temperature requires safety awareness:

Safety Checklist:

- Wear heat-resistant gloves

- Work in well-ventilated area

- Keep flammable materials away

- Use press on stable surface

- Don’t leave press unattended

Frequently Asked Questions

Q: What is the ideal sublimation on metal temperature?

A: 400°F (204°C) works best for most metal sublimation projects.

Q: Can you use the same temperature for all metals?

A: Most coated metals work at 400°F, but always test as some may need 5-10°F adjustments.

Q: How long to press metal sublimation signs for outdoor use?

A: 60-75 seconds at 400°F ensures deeper ink penetration for outdoor durability.

Q: Is an iron ever suitable for metal sublimation?

A: No, irons cannot provide the consistent temperature and pressure needed for quality metal sublimation.

Q: What happens if temperature is too high?

A: Overheating can yellow the coating, cause bubbling, or create brown spots on your design.

Leave a Reply

You must be logged in to post a comment.