Sublimation metal refers to specially coated aluminum or steel sheets designed for heat transfer printing.

These metals have a polyester or polymer coating that allows sublimation inks to bond at high temperatures, creating vivid, long-lasting images directly on the surface.

It is a popular choice for photo panels, signs, nameplates, and personalized products.

What Is Metal Sublimation?

Metal sublimation is a printing process that uses heat and pressure to transfer images from sublimation paper to a coated metal surface.

The ink turns into gas and embeds itself into the coating, producing a durable, full-color image.

Main features:

- Bright, glossy, and professional look

- Scratch and UV resistant

- Waterproof and fade-resistant

- Lightweight and easy to cut

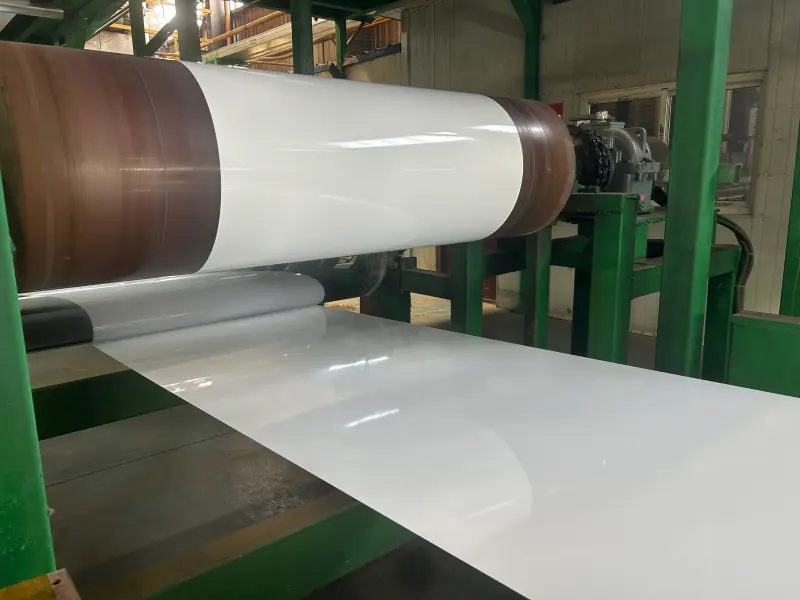

How to Make a Sublimation Metal Sheet

To create a sublimation metal sheet, manufacturers follow these steps:

| Step | Process Description |

|---|---|

| 1 | Choose high-purity aluminum alloy (e.g. 1060, 5052, or 6061) |

| 2 | Clean and polish the surface for smoothness |

| 3 | Apply polyester coating evenly |

| 4 | Bake at 200°C to fix the coating |

| 5 | Cut to sizes like A4, A3, 8×10, or 12×24 inches |

Once coated, the sheet is ready for printing using heat transfer sublimation.

Common Alloys and Sizes for Sublimation Metal

| Alloy Type | Thickness (mm) | Available Sizes (mm) | Application |

|---|---|---|---|

| 1060 Aluminum | 0.5 – 1.0 | 300×400 / 600×900 | Photo panels, crafts |

| 5052 Aluminum | 0.8 – 1.2 | 600×1200 / 1000×2000 | Signs, nameplates |

| 6061 Aluminum | 1.0 – 3.0 | Custom sizes | Industrial tags, art panels |

How to Print on Sublimation Metal

- Prepare the image – Use sublimation ink and paper.

- Clean the metal sheet – Remove dust and fingerprints.

- Align the image – Place the printed side of the paper on the coated side.

- Set your heat press:

- Temperature: 190–200°C (374–392°F)

- Time: 60–90 seconds

- Pressure: Medium to firm

- Cool down and peel off the paper carefully.

| Parameter | Recommended Setting |

|---|---|

| Temperature | 190–200°C |

| Time | 60–90 seconds |

| Pressure | Medium |

| Cooling | Air or flat surface |

This process produces a smooth, glossy finish with vibrant colors.

How Long Do You Sublimate Metal?

The ideal sublimation time depends on the coating and thickness:

- Thin sheets (0.5 mm): 55–65 seconds

- Standard sheets (1.0 mm): 70–90 seconds

- Thick sheets (1.5 mm+): up to 100 seconds

Overheating may cause discoloration or dullness, so maintaining the correct time and temperature is crucial.

What Are the Downsides of Metal Sublimation?

While sublimation metal has many benefits, there are a few limitations:

| Limitation | Explanation |

|---|---|

| Requires coating | Only coated metal can be sublimated |

| Temperature sensitivity | Overheating may cause color fading |

| Higher cost | Coated metals cost more than paper or MDF |

| Limited color range | Metallic backgrounds may slightly affect color tone |

Despite these, sublimation metal remains a top choice for professional printing due to its durability and premium finish.

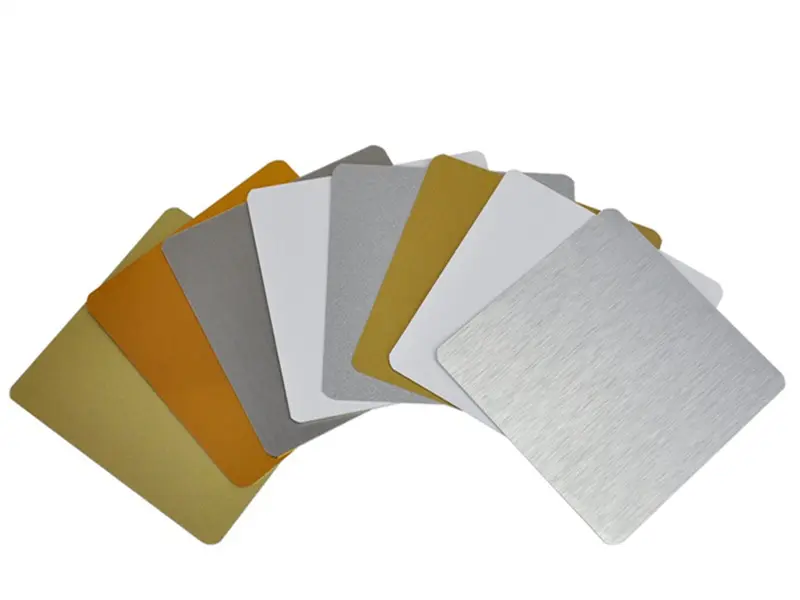

Types of Sublimation Metal Sheets

| Type | Finish | Best Use |

|---|---|---|

| White Gloss | Bright and colorful photo prints | Photography panels |

| Silver Gloss | Metallic effect with shine | Signboards, labels |

| Gold Gloss | Luxury look | Awards, certificates |

| Matte White | Non-reflective | Interior signage |

| Brushed Silver | Industrial style | Office nameplates |

Applications of Sublimation Metal

Sublimation metal sheets are used in many industries and creative projects:

- Photo printing – HD metal photo panels

- Awards & certificates – plaques and trophies

- Advertising – store signs, product labels

- Interior décor – custom wall art and displays

- Industrial use – nameplates and serial number tags

These sheets combine beauty, precision, and longevity, making them ideal for both artistic and professional applications.

Specifications Overview

| Item | Details |

|---|---|

| Material | Aluminum (coated for sublimation) |

| Thickness | 0.5 mm – 1.5 mm |

| Size | A4 / A3 / 8×10 / 12×24 inches |

| Surface Finish | Glossy, Matte, Brushed |

| Printing Method | Heat transfer sublimation |

| Printing Time | 60–90 seconds at 190–200°C |

FAQ: Quick Answers

Can you sublimate on steel?

Only if it’s coated with a sublimation layer or treated with polymer spray.

Is sublimation on metal waterproof?

Yes, sublimation inks fuse with the coating, making it water and UV-resistant.

Do colors fade over time?

With proper coating and care, images can last more than 10 years.

What finish is best for photo panels?

Gloss white offers the brightest colors and best image clarity.

What Is Sublimation Metal?

Sublimation metal provides a modern, high-quality solution for printing durable and colorful designs on aluminum sheets.

It is perfect for photographers, decorators, and manufacturers who need long-lasting, fade-resistant surfaces.

By controlling temperature, time, and coating quality, anyone can achieve professional-grade metal prints suitable for both personal and industrial use.

Leave a Reply

You must be logged in to post a comment.