How to Treat Aluminum for Sublimation?This process allows for stunning Dye Sublimation onto Aluminum, transforming ordinary metal into vibrant artwork. Whether you’re looking to create personal keepsakes or professional Dye-Sublimation Aluminum Prints, understanding this “treatment” is crucial for achieving high-quality results that stand the test of time.

Aluminum Sheets for Sublimation

Aluminum sheets for sublimation are specially coated to accept dye sublimation ink. Proper treatment ensures the ink adheres smoothly and produces vibrant, long-lasting images. Sublimation-ready aluminum sheets are widely used for:

- Photo panels

- License plates

- Customized gifts

- Industrial tags and signage

Dye Sublimation onto Aluminum

Sublimation printing transfers dyes into aluminum surfaces under heat and pressure. Key benefits of sublimation on treated aluminum include:

- Scratch-resistant surface

- UV-protection

- Waterproof finish

- High-definition color reproduction

| Alloy | Features | Best Use |

|---|---|---|

| 1060 | Pure aluminum, low cost | Indoor small prints |

| 3003 | Corrosion resistant | Outdoor photo panels |

| 5052 | High corrosion resistance | Industrial signs |

How to Sublimate Aluminum Photo Panels

To get perfect prints on aluminum photo panels, follow these steps:

- Clean the aluminum sheet – Remove dust, grease, and fingerprints.

- Apply protective coating – Use sublimation coating if the sheet is untreated.

- Print your design – Use a sublimation printer and transfer paper.

- Heat press – Apply correct temperature, pressure, and time (see FAQ table).

- Cool and peel – Let the sheet cool, then remove the paper carefully.

| Step | Temperature | Time | Pressure |

|---|---|---|---|

| Heat Press | 180–200°C | 60–120s | Medium |

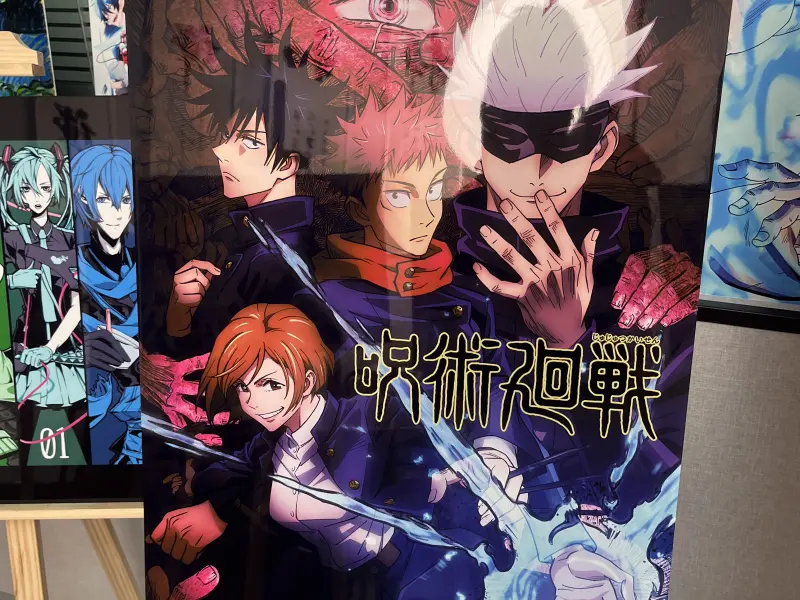

Dye-Sublimation Aluminum Prints

Dye-sublimation on aluminum offers flexibility for various applications:

Industrial use – ID tags, machinery labels

Home décor – Wall art, framed photos

Corporate branding – Office signage, logos

Retail displays – Product boards, shop signs

Personal gifts – Custom photo panels, awards

Why is This Treatment Essential for Dye Sublimation?

The treated surface is what distinguishes a regular aluminum sheet from one capable of producing high-definition, durable Dye-Sublimation Aluminum Prints. Here’s why this polymer coating is so vital:

- Ink Absorption: It provides a porous, yet protective, layer that can absorb and permanently encapsulate the sublimation dyes.

- Vibrancy and Detail: The coating is engineered to hold the ink pigments in a way that maximizes color saturation and image sharpness.

- Durability: Once infused, the ink is protected by the coating, making the print resistant to scratches, water, chemicals, and UV fading.

- Longevity: This treatment ensures your Dye-Sublimation Aluminum Prints will last for decades without significant degradation.

Essentially, the “treatment” is what elevates regular aluminum into premium aluminum sheets for sublimation, ready to become beautiful metal prints.

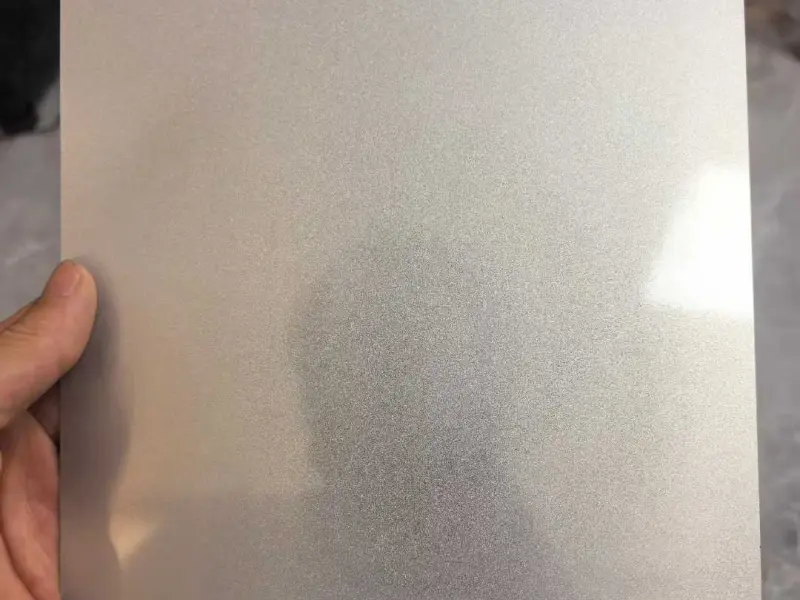

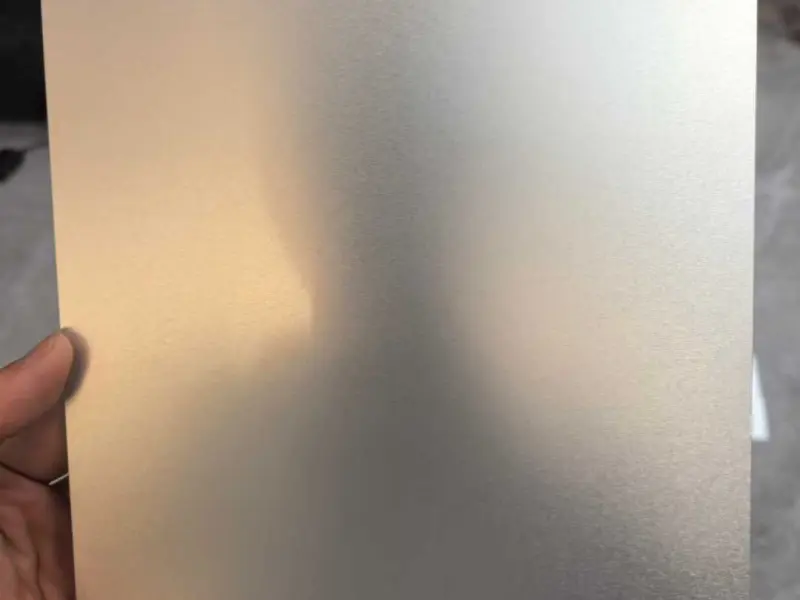

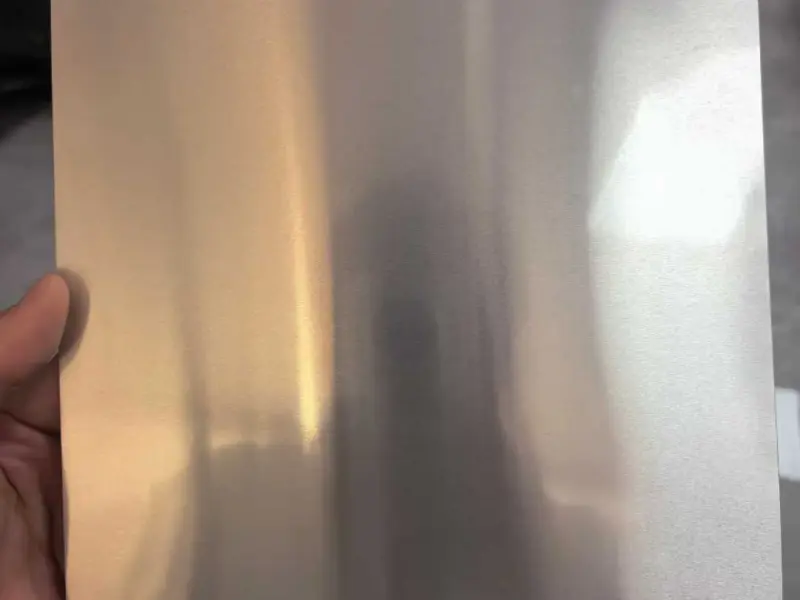

Types of Aluminum Sheets for Sublimation

Aluminum sheets for sublimation come in various finishes and thicknesses, each offering a distinct aesthetic and purpose. Understanding these options helps you choose the perfect panel for your Dye-Sublimation Aluminum Prints.

| Finish Type | Description | Common Use Cases | Common Thickness |

|---|---|---|---|

| White Glossy | Brightest whites, highly reflective, vibrant colors. | High-impact photos, fine art, vivid signage. | 0.5 mm – 1.1 mm |

| White Matte | Reduces glare, softer appearance, less reflective. | Art reproductions, professional text-based signs, less distracting displays. | 0.5 mm – 1.1 mm |

| Satin Silver | Metallic silver background shows through white areas. | Industrial designs, black & white photos, modern art with metallic hints. | 0.5 mm – 1.1 mm |

| Clear Glossy | Raw aluminum texture visible, colors appear translucent. | Unique artistic effects, industrial signage, adding metallic depth to images. | 0.5 mm – 1.1 mm |

| Brushed Aluminum | Textured, visible grain, industrial or rustic look. | Rustic signs, abstract art, awards, industrial labels. | 0.5 mm – 1.1 mm |

These pre-treated panels are the foundation for any successful Dye Sublimation onto Aluminum project.

FAQ: Your Questions About Aluminum Sublimation

Can you do sublimation on aluminum?

Yes, absolutely! You can do sublimation on aluminum, but only if the aluminum has been specially pre-treated with a polymer coating. This coating is what accepts the sublimation dyes. Regular, untreated aluminum will not work for sublimation.

How to treat metal for sublimation?

To treat metal for sublimation (as an end-user), you don’t typically apply the polymer coating yourself. This is a complex industrial process performed by specialized manufacturers. For practical purposes, “treating” metal for sublimation means purchasing high-quality, pre-coated aluminum sheets for sublimation from a reputable supplier. These blanks are already perfectly prepared to receive sublimation inks. Attempting to coat metal yourself at home is not recommended due to the precision and specialized materials required for a durable and consistent coating.

How to sublimate an image to aluminum?

Once you have your pre-treated aluminum sheets for sublimation, the process to sublimate an image to aluminum involves a few key steps:

- Prepare Your Artwork: Create or select your image. Crucially, mirror (horizontally flip) your image in your design software before printing.

- Print on Sublimation Paper: Use a sublimation printer with sublimation inks to print your mirrored design onto special sublimation transfer paper.

- Clean the Aluminum Panel: Ensure your aluminum photo panel is spotless. Use a lint-free cloth and, if needed, a mild cleaner (like rubbing alcohol) to remove any dust, fingerprints, or smudges.

- Position & Secure: Place the printed sublimation paper face-down onto the coated side of the aluminum panel. Secure it firmly with heat-resistant tape to prevent any shifting during pressing, which can cause ghosting.

- Heat Press Setup: Place protective paper (blowout paper) on your heat press’s bottom platen. Place the taped aluminum panel (paper side up) on top of the protective paper. Cover with another sheet of protective paper.

- Press: Close the heat press and apply the recommended temperature, time, and pressure settings. (See the table below for general guidelines).

- Cool & Reveal: After pressing, carefully open the press. The aluminum will be very hot. Let it cool slightly, then gently peel off the sublimation paper to reveal your brilliant Dye-Sublimation Aluminum Print.

What temperature and time for aluminum sublimation?

Getting the right temperature and time for aluminum sublimation is vital for a successful, vibrant transfer. While settings can vary slightly depending on your specific heat press, aluminum blank manufacturer, and ink, here are general recommended ranges:

| Setting | Recommended Range | Purpose and Notes |

|---|---|---|

| Temperature | 380°F – 400°F (193°C – 204°C) | Essential for the sublimation inks to turn into a gas and infuse into the coating. |

| Time | 45 – 90 seconds | Allows sufficient time for the ink to fully transfer. Thicker panels or darker images might need a bit longer. |

| Pressure | Medium to Heavy (Firm & Even) | Ensures constant, full contact between the sublimation paper and the aluminum coating. Crucial for consistent ink transfer. |

| Protection | Blowout paper (top & bottom of blank) | Prevents residual ink from damaging your heat press. |

Always consult the specific instructions provided with your aluminum sheets for sublimation and perform test prints if you are unsure of the exact settings for your setup.

Why Choose Our Aluminum Sheets for Sublimation

- Pre-coated for easy sublimation

- High-quality alloys for durability and vibrancy

- Multiple sizes and thickness options

- Reliable factory supply for bulk orders

- Fast delivery and technical support

| Size | Thickness | Finish |

|---|---|---|

| A4 | 0.5–0.7 mm | Glossy / Matte |

| 12×18 | 0.8–1.2 mm | Satin Silver / White |

| Custom | 0.5–1.5 mm | Full customization |

By using properly treated aluminum sheets and following these steps, you can achieve high-definition, durable, and visually stunning sublimation prints. Whether for personal projects or commercial production, sublimation aluminum panels are versatile and reliable.

Leave a Reply

You must be logged in to post a comment.