Sublimation Printing on Aluminum: Create Vibrant Metal Prints

Sublimation printing on aluminum transforms coated aluminum panels into stunning, permanent prints with incredible color vibrancy. This process is ideal for photographers, artists, and businesses looking to create high-quality metal displays. Here’s everything you need to know to achieve perfect results.

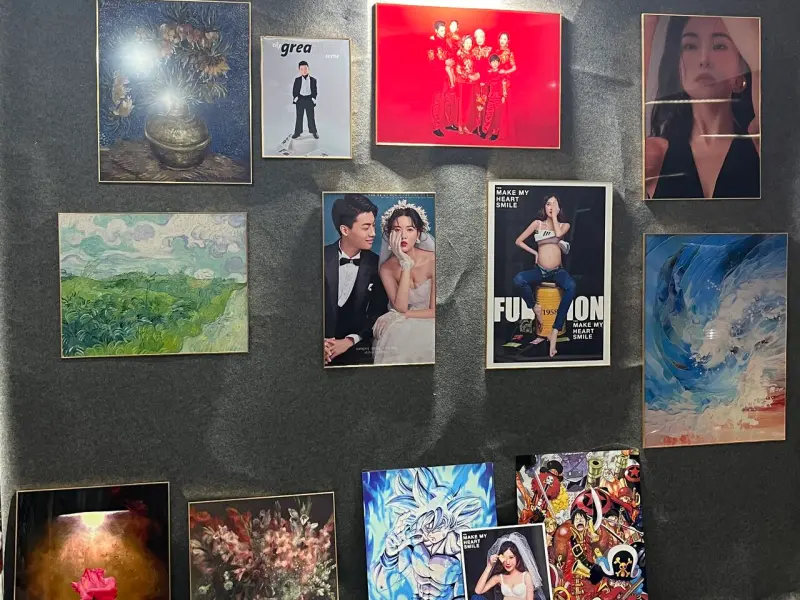

2025 Yiwu Exhibition Aluminum Sublimation sheet

What is Sublimation Printing on Aluminum?

Sublimation printing uses heat to transfer dye into a special polymer coating on aluminum. The ink becomes a permanent part of the material, creating scratch-resistant, fade-resistant images.

Key Advantages:

- Vibrant Colors: Bright, high-resolution prints

- Durability: Resists fading, scratches, and moisture

- Professional Finish: Modern glossy or matte appearance

- Longevity: Lasts for decades with proper care

Sublimation Aluminum Photo Panels: Types and Sizes

| Panel Type | Surface Finish | Best For | Available Sizes |

|---|---|---|---|

| White Glossy | Shiny white base | Vibrant photos, artwork | 8×10″, 11×14″, 16×20″, 24×36″ |

| White Matte | Non-reflective matte | Portraits, text displays | A4, 12×12″, 18×24″ |

| Silver Metallic | Brushed metal look | Modern designs, logos | 8×8″, 12×18″, 20×30″ |

| Clear Coated | Natural aluminum show-through | Industrial style, special effects | Custom sizes available |

Panel Thickness Options:

- Thin (0.8mm): Lightweight, ideal for framing

- Standard (1.5mm): Most popular, rigid enough for hanging

- Thick (3.0mm): Premium feel, no framing needed

HD Sublimation Aluminum Print: Achieving High Definition

Requirements for HD Results:

- Image Quality: 300 DPI or higher resolution

- Proper Coating: Even polymer coating on aluminum

- Correct Settings: Precise temperature and time control

- Quality Ink: Fresh sublimation ink cartridges

HD Print Benefits:

- Sharp details and smooth gradients

- Accurate color reproduction

- Professional gallery-quality results

- Suitable for close-up viewing

Dye Sublimation onto Aluminum: Process Overview

Step-by-Step Process:

- Design Preparation

- Use high-resolution images (300+ DPI)

- Mirror image horizontally before printing

- Size correctly for your aluminum panel

- Printing

- Use dedicated sublimation printer

- Load sublimation paper properly

- Ensure even ink coverage

- Heat Press Settings Panel Type Temperature Time Pressure Thin (0.8mm)385°F (196°C)50-60 seconds Medium Standard (1.5mm)395°F (202°C)60-70 seconds Medium Thick (3.0mm)400°F (204°C)75-90 seconds Firm

- Finishing

- Peel paper while warm (180-degree angle)

- Inspect for imperfections

- Allow to cool completely before handling

Dye-Sublimation Printing: Equipment Requirements

Essential Equipment:

- Sublimation Printer: Epson, Sawgrass, or Ricoh models

- Heat Press: Swing-away style with even pressure distribution

- Sublimation Ink: High-quality, manufacturer-recommended

- Sublimation Paper: Coated for optimal ink release

Equipment Comparison:

| Equipment Type | Best For | Capacity | Price Range |

|---|---|---|---|

| Entry-Level | Hobbyists, small businesses | Up to 13×19″ | $300-600 |

| Professional | Print shops, photographers | Up to 24×36″ | $1,000-3,000 |

| Industrial | Large-scale production | 40″++ | $5,000++ |

Metal Printing | Dye Sublimation: Applications

Common Uses:

- Photo Displays: Family photos, wedding pictures, portraits

- Business Signs: Office signage, retail displays, nameplates

- Home Decor: Wall art, kitchen decor, personalized gifts

- Art Reproductions: Gallery prints, limited editions

- Awards & Recognition: Trophies, achievement plaques

Industry Applications:

- Photography studios and labs

- Sign making businesses

- Interior design companies

- Corporate marketing departments

- Gift and souvenir shops

Sublimating On Coated Sublimation Aluminium: Technical Details

Coating Specifications:

- Coating Type: Heat-activated polymer

- Coating Thickness: 15-25 microns

- Activation Temperature: 380°F+ (193°C+)

- Color Compatibility: Works with all sublimation inks

Quality Indicators:

- Even, smooth coating surface

- Pure white background color

- Consistent thickness across panel

- No visible defects or scratches

FAQ: Sublimation Printing on Aluminum

Q1: How to use sublimation printer on aluminum?

A: Use these steps:

- Mirror your design in editing software

- Print on sublimation paper using sublimation ink

- Press onto coated aluminum with correct heat settings

- Peel carefully while warm

Q2: Can you do sublimation on aluminum?

A: Yes, but only on specially coated aluminum panels. Regular aluminum won’t work.

Q3: How to sublimate an image to aluminum?

A: Follow this process:

- Design → Print → Press → Peel

- Use recommended temperature and time settings

- Ensure even pressure during pressing

Q4: What temperature and time for aluminum sublimation?

A: Typical settings:

- Temperature: 385-400°F (196-204°C)

- Time: 50-90 seconds (depending on thickness)

- Pressure: Medium to firm

Q5: How do you print on aluminum?

A: Two main methods:

- Sublimation: For coated aluminum, requires heat press

- UV Printing: For uncoated aluminum, uses special printers

Q6: Why did my print come out blurry?

A: Common causes and solutions:

- Paper movement: Use heat-resistant tape

- Incorrect pressure: Adjust press settings

- Moisture: Pre-press for 5-10 seconds to dry

Troubleshooting Common Issues

| Problem | Possible Causes | Solutions |

|---|---|---|

| Faded Colors | Low temperature, short time | Increase temperature by 10°F or time by 15 seconds |

| Ghosting | Paper shifting during press | Better tape securing, check press evenness |

| Yellowing | Excessive heat/time | Reduce temperature by 15°F or time by 20 seconds |

| Uneven Transfer | Uneven pressure, warped plate | Check press calibration, use thicker aluminum |

| Color Banding | Clogged print heads, low ink | Clean print heads, replace ink cartridges |

Professional Tips for Best Results

Pre-Press Checklist:

- Clean aluminum surface with alcohol

- Calibrate heat press temperature

- Test print on small piece first

- Use fresh sublimation paper

- Secure paper with heat-resistant tape

Color Management:

- Use ICC profiles provided by ink manufacturer

- Calibrate monitor regularly

- Maintain consistent lighting when editing

- Keep printer nozzles clean

Equipment Maintenance:

- Clean heat press plate regularly

- Store paper in dry conditions

- Use original ink cartridges

- Update printer firmware

Why Choose Aluminum Sublimation Printing?

Compared to Other Methods:

| Feature | Sublimation | UV Printing | Traditional Printing |

|---|---|---|---|

| Durability | Excellent | Good | Fair |

| Color Vibrancy | Best | Very Good | Good |

| Cost | Moderate | Higher | Lower |

| Equipment Needed | Heat press + printer | Special printer | Standard printer |

Benefits Summary:

- Longest-lasting results (50+ years indoors)

- Most vibrant color reproduction

- Professional gallery-quality finish

- Scratch and fade resistant

Getting Started with Aluminum Sublimation

Beginner’s Kit Recommendations:

- Small heat press (15×15″)

- Entry-level sublimation printer

- Assorted aluminum panels (A4 and 8×10″)

- Basic sublimation ink and paper

- Heat-resistant tape and gloves

First Project Ideas:

- 8×10″ family photo

- A4 business sign

- 12×12″ abstract art

- 8×8″ personalized gift

Sublimation Printing on Aluminum for projects

Sublimation printing on aluminum produces stunning, durable results that outperform other printing methods. By following the proper techniques and settings, you can create professional-quality metal prints that will last for decades. Start with small projects to master the process, then expand to larger productions.

Ready to begin? Contact us for materials and guidance!

Leave a Reply

You must be logged in to post a comment.