Printing on aluminum sublimation sheets requires precision and understanding of the material’s unique properties. These five essential tips will help you achieve professional, vibrant results that showcase the full potential of aluminum sublimation printing.

1. Surface Preparation: The Foundation of Quality

Why it matters: Proper surface preparation ensures optimal ink adhesion and prevents defects.

| Step | Tool/Method | Purpose | Frequency |

|---|---|---|---|

| Cleaning | Isopropyl alcohol (99%) | Remove oils and contaminants | Before every print |

| Inspection | LED light panel | Detect surface imperfections | Before each job |

| Handling | Cotton gloves | Prevent fingerprints | Always |

Key Points:

- Use lint-free cloths for cleaning

- Allow surface to fully dry before printing

- Store sheets in original packaging until use

- Avoid touching surface with bare hands

2. Printer calibration: Color Accuracy Essentials

Critical Settings for Optimal Results:

| Parameter | Recommended Setting | Effect on Print Quality |

|---|---|---|

| Resolution | 1440 dpi | Maximum detail sharpness |

| Color Profile | Custom ICC profile | Accurate color reproduction |

| Print Speed | 4-6 passes | Optimal ink deposition |

| Ink Density | 100-110% | Enhanced color vibrancy |

Calibration Checklist:

- Perform nozzle checks before each print session

- Create material-specific ICC profiles

- Use manufacturer-recommended ink

- Maintain consistent printer maintenance

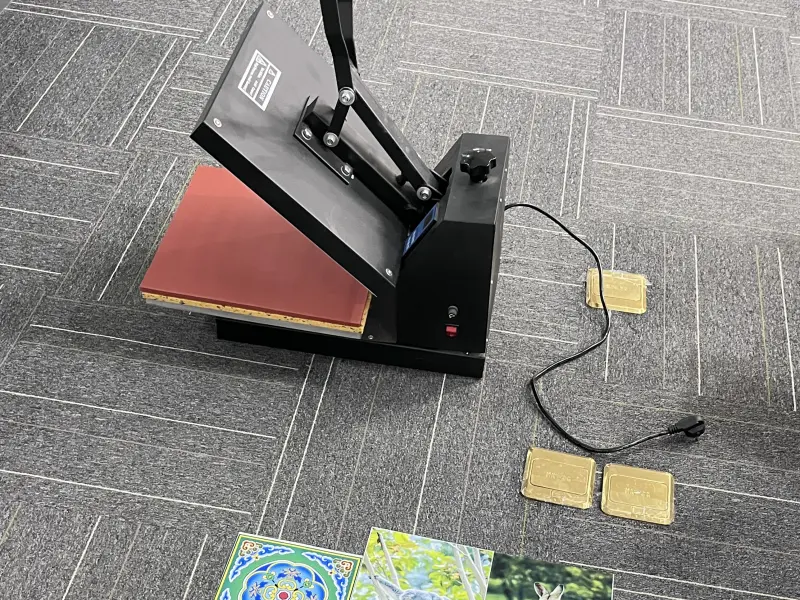

3. Heat Press Settings: Precision Temperature Control

Optimal Parameters by Sheet Type:

| Sheet Type | Temperature | Time | Pressure | Notes |

|---|---|---|---|---|

| Standard White | 190°C (374°F) | 60 seconds | Medium | Most common setting |

| HD Coated | 185°C (365°F) | 45 seconds | Light | Prevents coating damage |

| Metallic Finish | 195°C (383°F) | 75 seconds | Medium-High | Enhances metallic effect |

| Textured Surface | 200°C (392°F) | 90 seconds | High | Ensures complete transfer |

Pro Tips:

- Use infrared thermometer to verify platen temperature

- Pre-press for 5-10 seconds to remove moisture

- Use Teflon sheet protection

- Allow natural cooling before handling

4. Design Optimization for Aluminum Substrates

Design Considerations Table:

| Design Element | Recommendation | Reason |

|---|---|---|

| Backgrounds | Use white space strategically | Aluminum brightens colors |

| Text Size | Minimum 8pt for readability | Prevents bleeding |

| Color Saturation | Increase by 10-15% | Compensates for substrate brightness |

| Image Resolution | 300 PPI minimum | Maintains sharpness |

| Bleed Area | 3mm additional | Ensures edge-to-edge coverage |

Software Settings:

- Adobe Photoshop: Use “Hard Matte” proof setup

- Illustrator: Convert all text to outlines

- CorelDRAW: Enable “High Quality” rendering

- Always mirror designs before printing

5. Post-Processing and Protection

Finishing Techniques for Durability:

| Method | Application | Benefits | Equipment |

|---|---|---|---|

| UV Coating | Outdoor displays | UV protection, scratch resistance | Spray system or roller |

| Laminating | High-traffic areas | Enhanced durability, easy cleaning | Cold laminator |

| Frame Mounting | Gallery prints | Professional presentation, protection | Aluminum frame system |

| Edge Sealing | Outdoor applications | Moisture protection, longer lifespan | Clear sealant |

Quality Control Checklist:

- Inspect under bright light for defects

- Check color consistency across batch

- Verify edge-to-edge coverage

- Test adhesion with cross-hatch test

- Measure color accuracy with spectrophotometer

Troubleshooting Common Issues

| Problem | Cause | Solution | Prevention |

|---|---|---|---|

| Faded Colors | Low temperature | Increase press temperature | Verify temperature calibration |

| Blurry Images | Movement during press | Secure material properly | Use heat-resistant tape |

| Orange Peel Texture | Moisture contamination | Pre-press longer | Store in dry environment |

| Color Banding | Clogged print heads | Run head cleaning cycle | Regular printer maintenance |

| Poor Adhesion | Dirty surface | Improve cleaning process | Handle with gloves always |

Recommended Equipment Setup

Essential Tools for Perfect Results:

| Equipment Type | Recommended Models | Budget Range | Key Features |

|---|---|---|---|

| Sublimation Printer | Epson SureColor F570 | $2,500-$3,500 | 4-color dedicated sublimation |

| Heat Press | Geo Knight DK20S | $1,800-$2,200 | Swing-away design, digital controls |

| Color Management | X-Rite i1Studio | $500-$700 | Professional color calibration |

| Cutting System | Graphtec CE6000-40 | $1,200-$1,600 | Precision contour cutting |

Maintenance Schedule

| Task | Frequency | Time Required | Importance |

|---|---|---|---|

| Printer Head Cleaning | Daily | 5 minutes | Critical |

| Heat Press Calibration | Weekly | 15 minutes | High |

| Color Profile Verification | Monthly | 30 minutes | High |

| Full System Maintenance | Quarterly | 2 hours | Medium |

| Equipment Deep Clean | Annually | 4 hours | Medium |

FAQ

Q: How long should I wait after printing before pressing?

A: Wait 10-15 minutes to allow ink to set, but press within 4 hours for best results.

Q: Can I reuse misprinted sheets?

A: No, the coating is compromised after first press. Always use fresh sheets for production work.

Q: What’s the best way to store aluminum sheets?

A: Keep in original packaging, flat storage, temperature-controlled environment (15-25°C), 40-60% humidity.

Q: How do I prevent ghosting?

A: Use light pressure during initial contact, ensure even heat distribution, and avoid moving during transfer.

Q: Can I print on both sides?

A: No, aluminum sublimation sheets are single-sided only. The coating is applied to one surface only.

Conclusion

Perfect printing on aluminum sublimation sheets requires attention to detail at every step. By following these five essential tips—proper surface preparation, precise printer calibration, optimal heat press settings, design optimization, and careful post-processing—you can achieve stunning, professional results consistently.

Key Takeaways:

- Always start with perfectly clean surfaces

- Invest time in proper equipment calibration

- Follow manufacturer specifications for temperature and pressure

- Design specifically for aluminum’s unique properties

- Implement appropriate protective finishes for your application

Remember that practice and consistency are key to mastering aluminum sublimation printing. Keep detailed records of your successful settings and learn from each project to continuously improve your results.

Final Pro Tip: Always order extra sheets for testing and calibration when working with new designs or materials. This small investment will save time, materials, and frustration in the long run while ensuring perfect results for your clients.

Leave a Reply

You must be logged in to post a comment.