Aluminium sublimation printing has become a popular method for creating vivid, durable images on metal surfaces. Whether you’re producing custom photo panels, signage, or promotional items, it’s important to know the correct heat press settings for aluminum sublimation to get the best results.

This guide covers temperature, time, pressure, and tips for sublimating on aluminum — plus comparisons with other materials like cotton and polyester.

Specification of Sublimation Aluminum Sheets

Before choosing heat press settings, make sure your aluminum sheets are:

- Sublimation coated (polymer layer)

- Flat and smooth surface

- Standard sizes: 4″x6″, 8″x10″, 12″x18″, etc.

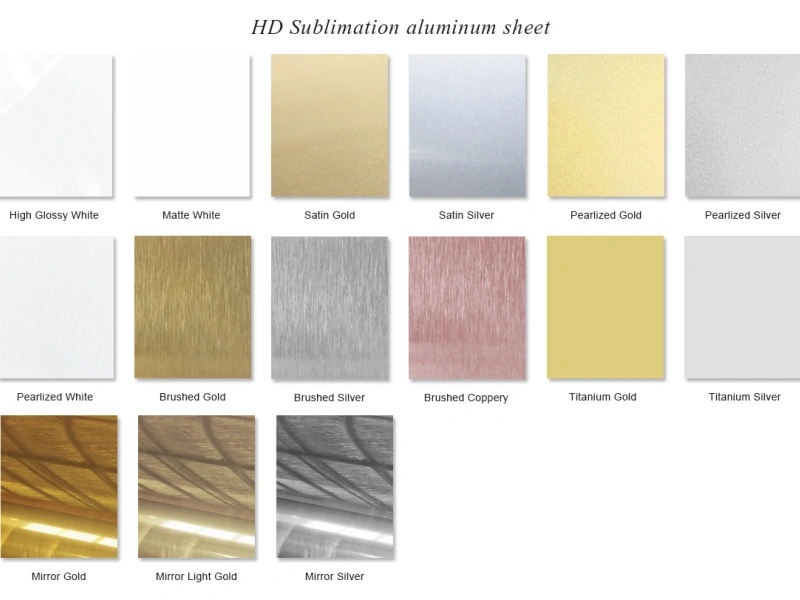

- Available in white, silver, gold, or brushed finishes

Classification of Sublimation Applications on Aluminum

- Photo panels

- Signboards

- Nameplates

- Trophies and awards

- Industrial tags

- Wall décor

Each type may vary slightly in recommended heat press settings based on thickness and coating.

What Temperature Do You Sublimate Aluminum?

The ideal sublimation temperature for aluminum is typically:

- 400°F (204°C)

This high temperature allows the sublimation ink to turn into gas and bond with the aluminum’s coated surface. For most aluminum blanks, 400°F is the standard.

What Setting Do You Sublimate Aluminum?

The full heat press settings for aluminum sublimation are:

- Temperature: 400°F (204°C)

- Time: 60 seconds to 90 seconds

- Pressure: Medium to firm pressure

- Face down: Place the printed side of sublimation paper against the aluminum coated side

- Protective paper: Use parchment or Teflon sheet to avoid ink bleed

What Is the Heat of Sublimation of Aluminum?

From a scientific perspective, the heat of sublimation of aluminum refers to the energy required to convert aluminum from solid to gas without passing through the liquid phase. While interesting, this is different from sublimation printing, which only involves the ink sublimating — not the metal itself.

So, don’t confuse aluminum sublimation printing with aluminum’s sublimation point in chemistry.

What Temperature Do You Heat Press Aluminum?

For best results in a heat press machine, follow these steps:

- Preheat your press to 400°F (204°C)

- Clean the aluminum surface to remove dust/oil

- Tape the sublimation paper securely with heat-resistant tape

- Press for 65–75 seconds (varies by product size)

- Remove the item immediately and let it cool flat

How to Use a Sublimation Printer on Aluminum

- Design your image using graphic software like Photoshop or CorelDRAW

- Print using a sublimation printer with sublimation ink

- Use transfer paper to carry the image

- Align paper to aluminum blank

- Heat press with correct settings

- Peel the paper off after pressing

Key Tips:

- Use mirror image for designs with text

- Avoid touching the sublimated area immediately — it’s hot and fragile

- Practice first on a sample blank

Sublimation Heat Press Settings for Cotton

Cotton cannot bond with sublimation ink directly. But you can use sublimation coating spray or sublimation vinyl as a base.

- Temperature: 380°F (193°C)

- Time: 40–60 seconds

- Coating required: Yes

- Result: Not as vivid as on polyester or aluminum

Sublimation Heat Press Temperature for Polyester

Polyester works perfectly with sublimation ink. Recommended settings:

- Temperature: 380°F – 400°F

- Time: 45–60 seconds

- Fabric content: 100% polyester for best results

This method is commonly used for t-shirts, jerseys, sportswear, and flags.

Heat Press Settings for Sublimation on 50/50 Fabric

Fabrics that are 50% cotton and 50% polyester do not produce the same vibrant prints. Only the polyester fibers bond with sublimation ink.

- Temperature: 380°F

- Time: 50 seconds

- Tip: Use Siser EasySubli or sublimation HTV for better results

Expect slightly faded or vintage-looking designs.

Benefits of Sublimating on Aluminum

- High-resolution prints

- Long-lasting and fade-resistant

- Waterproof and weather-resistant

- Ideal for indoor and outdoor use

- Scratch and chemical resistant

- No peeling or cracking over time

Common Applications for Aluminium Sublimation

- Home décor (wall photos, plaques)

- Office signs and door plates

- Retail displays

- Industrial labeling

- Personalized gifts (keychains, clocks, coasters)

- School and sports awards

Conclusion

Understanding the heat press setting for aluminium sublimation is crucial for achieving professional-quality results. Stick to:

- 400°F (204°C)

- 65–90 seconds

- Medium pressure

Whether you’re making custom photo panels or industrial tags, sublimation on aluminum delivers durable and vibrant outcomes.

If you’re looking for a reliable aluminum sublimation sheet supplier, we can help you with a wide range of coated aluminum blanks and printing materials.

Leave a Reply

You must be logged in to post a comment.