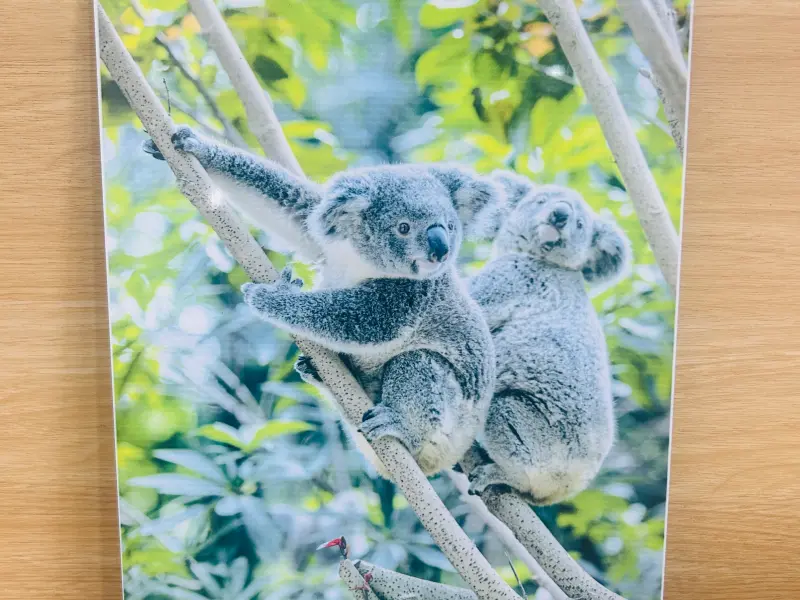

Sublimation metal sheets are coated aluminum sheets made for image transfer. With heat and sublimation ink, photos, designs, and logos are printed directly onto the surface. These sheets create bright colors, sharp details, and long-lasting results. They are popular for photo printing, wall decoration, signage, and awards.

Classification of Sublimation Metal Sheets

Sublimation sheets come in several categories.

| Classification | Description |

|---|---|

| Photo Panels | Used for printing photos and wall art |

| Plaques & Awards | Perfect for schools, offices, and events |

| Nameplates & Signs | Door plates, office tags, hotel signs |

| Keychain Sheets | Cut into small pieces for gifts |

| Large Sublimation Sheets | Supplied in A4, A3, or custom sizes |

Thickness Options

Different thicknesses meet different needs.

| Thickness (mm) | Common Use |

|---|---|

| 0.3 mm | Labels, tags, small decorative items |

| 0.5 mm | Lightweight signs, small panels |

| 0.7 mm | Medium strength plaques, awards |

| 1.0 mm | Strong photo panels, wall decoration |

| 1.5–2.0 mm | Heavy-duty signage, displays |

Alloy Information

The alloy affects durability and printing quality.

| Alloy | Properties |

|---|---|

| 1060 | High purity aluminum, smooth surface, best for coating |

| 3003 | Good corrosion resistance, indoor and outdoor use |

| 5052 | Stronger, resistant to weather, perfect for signage |

Types of Sublimation Metal Sheets

There are several types based on surface finish and color.

| Type | Finish | Features |

|---|---|---|

| Glossy White Sheets | Bright white | Best for photo printing |

| Matte Sheets | Non-reflective | Professional look |

| Brushed Aluminum Sheets | Silver or gold brushed | Modern metallic style |

| Colored Sheets | Red, black, blue, etc. | Creative custom printing |

| Custom Cut Sheets | Circles, hearts, ovals | Personalized designs |

Factory Production

High-quality sublimation sheets are made in advanced factories:

- Automatic coating lines ensure smooth sublimation layer

- CNC cutting machines provide accurate sizes

- Strict inspection guarantees no scratches or defects

- Bulk supply available for global customers

What Are Sublimation Metal Sheets?

Sublimation metal sheets are high-grade aluminum panels that have been pre-coated with a unique polymer layer. This layer is engineered to accept dye-sublimation inks when heat and pressure are applied. Unlike traditional printing where ink sits on the surface, the dye-sublimation process infuses the dyes directly into this polymer coating, creating an image that is not only incredibly vibrant but also remarkably resistant to scratches, water, and UV fading.

Why Choose Sublimation Metal Sheets?

Opting for sublimation metal sheets as your printing substrate offers a host of compelling advantages:

- Exceptional Color Vibrancy: Experience colors that pop with a luminous intensity, bringing your images to life with stunning clarity.

- Superior Durability: The infused image is highly resistant to scratches, abrasions, water damage, and common household cleaners.

- UV Resistance: Prints on sublimation metal sheets exhibit excellent resistance to fading when exposed to sunlight, ensuring longevity.

- Modern Aesthetic: The sleek, metallic base combined with vibrant images creates a contemporary and high-end look.

- Lightweight: Despite their robustness, these aluminum sheets are surprisingly light, making them easy to handle, mount, and display.

- Versatility: Ideal for a wide range of applications, from personal keepsakes to commercial displays.

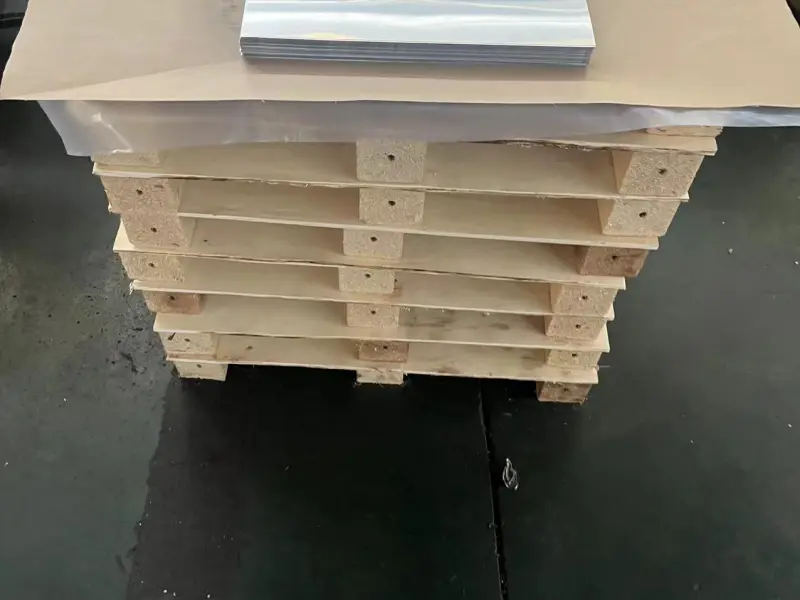

Packaging

To protect sublimation sheets during transport:

- Each sheet has protective film

- Packed with plastic or shrink wrap

- Cartons with corner protection

- Pallets for bulk export orders

Applications of Sublimation Metal Sheets

Sublimation sheets are widely used in different industries:

- Photo printing – family portraits, wedding photos

- Decorative panels – wall art, murals, posters

- Corporate use – nameplates, awards, certificates

- Retail and hotels – door signs, direction signs

- Promotional gifts – keychains, tags, souvenirs

The Sublimation Metal Sheets Factory Process

The production of high-quality sublimation metal sheets is a precise, multi-stage manufacturing process carried out in specialized factories:

- Aluminum Coil Sourcing: High-grade, flat-rolled aluminum coils are sourced, ensuring minimal imperfections.

- Cleaning and Pre-treatment: The aluminum surface undergoes a rigorous cleaning and chemical pre-treatment to prepare it for coating adhesion. This step is critical for the durability of the final product.

- Precision Coating Application: The aluminum is then fed through a sophisticated coating line where a multi-layer, proprietary polymer coating is applied. This coating is specially formulated to bond with the aluminum and to absorb dye-sublimation inks.

- Curing: The coated aluminum is passed through high-temperature ovens to cure the polymer coating, making it hard, durable, and ready for sublimation.

- Quality Control: Throughout the process, the sheets are inspected for coating uniformity, surface defects, and adherence to thickness specifications.

- Cutting and Finishing: The large coated rolls are then cut into individual sublimation metal sheets of various standard or custom sizes. Edges may be deburred or rounded.

FAQ about Sublimation Metal Sheets

Q1: What sizes are available?

A: Standard A4, A3, 30×40 cm, and custom sizes.

Q2: What is the best temperature for sublimation?

A: Usually 180–200°C for 45–60 seconds, depending on coating.

Q3: Can these sheets be used outdoors?

A: Yes, especially with 3003 or 5052 alloys.

Q4: Are the sheets safe from scratches before printing?

A: Yes, each sheet has a protective film.

Q5: What printers work with sublimation sheets?

A: Printers with sublimation inks (Epson, Sawgrass, etc.).