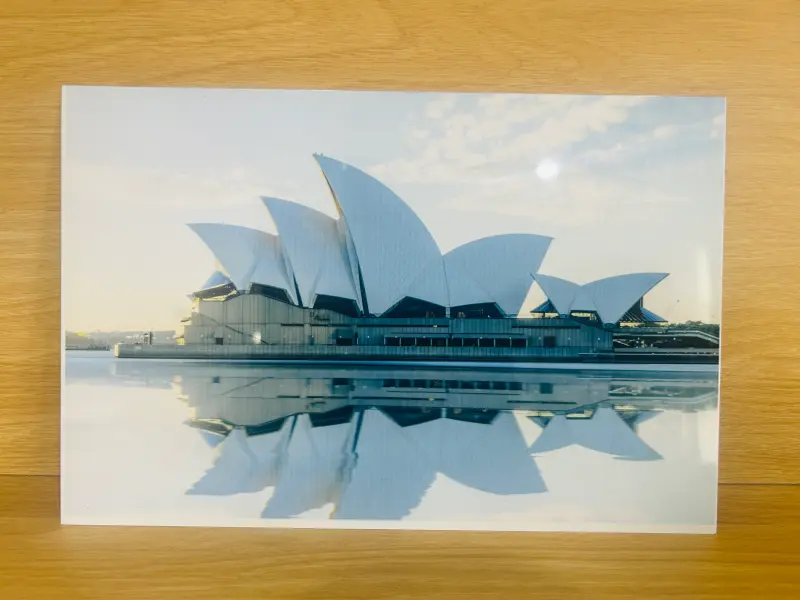

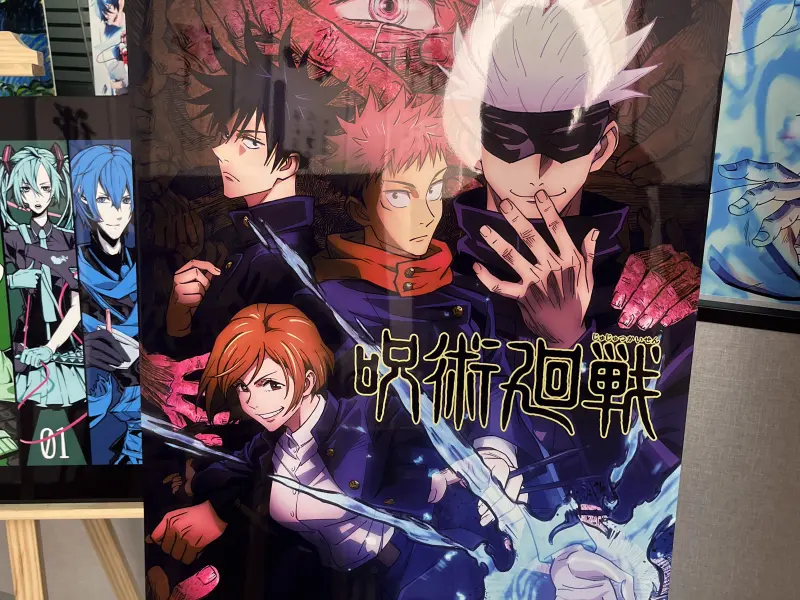

Sublimation metal blanks are specially coated aluminum sheets or panels designed for high-quality image transfer. These blanks allow sharp photo printing, vibrant colors, and long-lasting results. Many industries use sublimation blanks for photo gifts, signage, awards, and personalized products.

What Are Sublimation Metal Blanks?

Sublimation metal blanks are flat metal sheets specifically treated so that sublimation ink can bond to them during heat transfer.

The result is a sharp, long‑lasting image on the surface of the metal that looks like a continuous print, not a separate coating.

Classification

Metal blanks for sublimation come in several categories that determine the final look and feel of the finished product.

| Class | Common Use | Key Features |

|---|---|---|

| Aluminum 6000 Series | Jewelry, signage, decorative panels | Lightweight, strong |

| Aluminum 7075 Series | High‑performance parts, outdoor signs | High corrosion resistance |

| Duralumin | Industrial parts, hobby kits | Good machinability |

| Stainless Steel (e.g., 316L) | Marine applications, medical tools | Superior rust resistance |

These classes are chosen based on the alloy, finishing, and required durability.

Thickness Options

Thickness determines how the blank feels and how it bends. Standard thicknesses for sublimation metal blanks are:

| Thickness (mm) | Typical Application |

|---|---|

| 0.5 – 1.0 | Small plates, coins, tiny jewelry |

| 1.0 – 3.0 | Medium‑size panels, desk accessories |

| 3.0 – 10.0 | Large outdoor signs, wall panels |

| 10.0+ | Heavy‑purpose signage, structural supports |

Tip – Thinner blanks have a slicker finish, which helps the ink spread evenly. Thicker blanks hold more detail but may need special heat settings.

Sub‑Label

This is the secondary label on the back of the blank used during sublimation. It ensures proper alignment and provides a surface that holds the color transfer film firmly.

- Material – Polymer coating or embossed surface

- Size – Usually 30 mm × 30 mm for small blanks, up to 200 mm × 200 mm for panels

- Color – Typically white or silver to contrast the ink

A well‑designed sub‑label keeps the print crisp and prevents distortion during transfer.

Alloy Choices

Choosing the right alloy is critical for image quality and durability.

| Alloy | Finish | Best Use |

|---|---|---|

| Al 6061 | Satin, brushed | Jewelry, desk toppers |

| Al 7075 | Mirror, polished | Outdoor metal art |

| Al 7075 + 0.5 % Zr | Ultra‑smooth | High‑detail prototypes |

| Fe-25Cr-0.5Ti | 316L | Medical tools, marine signage |

Alloys with higher chromium content are more resistant to oxidation, making them ideal for outdoor or marine environments.

Types & Digitization

Subdividing by digital specifications helps designers pick the right blank for their workflow.

| Type | Digital Specification | Printing Size | Image Resolution |

|---|---|---|---|

| Basic | 300 dpi, single‑color | up to 100 mm × 100 mm | 900 × 900 pixels |

| Pro | 600 dpi, multi‑color | up to 200 mm × 200 mm | 1200 × 1200 pixels |

| Ultra‑HD | 1200 dpi, full‑color | up to 400 mm × 400 mm | 2400 × 2400 pixels |

| Large‑Format | 300 dpi, full‑color | up to 1000 mm × 1000 mm | 30,000 × 30,000 px approximate |

When you purchase a blank, the manufacturer will indicate the recommended resolution and color mode (CMYK or RGB) to match the sublimation printer.

Factory & Production Tips

Choosing a reputable factory ensures consistent quality and reliable delivery.

| Factory Feature | Why It Matters |

|---|---|

| Coating Process | Uniform polymer layer prevents ink bleeding |

| Surface Finish | Brushed or polished yields different visual effects |

| Heat‑Treatment | Stabilizes the metal, reduces warping during transfer |

| Testing Protocol | Guarantees the blank meets ISO standards for abrasion and corrosion |

Production Tips

- Preheat the blank to 75 °C before applying the printed backing.

- Use a heat press with a temperature range of 180–200 °C for 60–90 seconds—adjust if the metal is thicker.

- Keep the ambient humidity low to reduce ink drying time.

Packaging Choices

Proper packaging keeps blanks safe during shipping and storage.

| Packaging Type | Description | Common Use |

|---|---|---|

| Cardboard Box | Flat, reusable. Ideal for bulk orders. | Bulk shipments of small panels |

| Clamshell | Hard plastic shell, protective foam inside. | Medium‑size blanks that need extra cushioning |

| Shrink Wrap | Flexible, seals in place. Handy for individually packed items. | Small or custom blanks |

| Bulk Bales | Rolled or bagged. Economy packaging. | Very large orders of flat panels |

Add moisture‑absorbing packets if shipping to damp climates.

Applications – Where Sublimation Metal Blanks Shine

This concise list shows the versatility of sublimation metal blanks.

- Jewelry (rings, pendants, bracelets)

- Custom desk accessories (mouse pads, pen holders)

- Outdoor signage and billboards

- Industrial parts with branding or graphics

- Medical instruments marked with serial numbers

- Promotional items for events and trade shows

- Home décor panels and wall art

- Hobby kits (model cars, aircraft parts)

These uses demonstrate how the technology allows vibrant, durable prints on metal surfaces.

FAQ – Quick Answers to Common Questions

| Question | Answer |

|---|---|

| Can I use any printer for sublimation on metal blanks? | Only heat‑resistant sublimation printers that can reach 200 °C will work. Home printers need a compatible heat press. |

| Will the metal surface corrode after printing? | If the alloy is stainless or has a protective coating, corrosion is minimal. Keep surface dry. |

| How long does the print last? | With proper care, sublimated images on metal last many years, even outdoors, due to the dye being embedded in the surface. |

| Does the metal need polishing before printing? | A clean, lightly brushed finish helps the ink adhere; avoid heavy polishing that removes the protective coating. |

| Are sublimation metal blanks safe for food contact? | No, they are not FDA‑approved for food surfaces. Use non‑food‑grade alloys. |

| Can I size blanks myself? | Yes – many manufacturers offer custom cutting. Just let them know the exact dimensions. |

| What is the most common thickness for small jewelry? | 0.5 mm |