Welcome to the world of silver sublimation sheet! If you’re looking to create stunning, durable prints with a unique metallic shine, then these sheets are perfect for you. Silver sublimation sheets allow you to transfer your designs onto a special silver surface, resulting in vivid colors and incredible detail that truly stand out. They are a popular choice for artists, photographers, and businesses who want to add a touch of elegance and permanence to their work.

Key Aspects of Silver Sublimation Sheets

Here’s an overview of the essential characteristics of silver sublimation sheets:

| Feature | Description / Details |

|---|---|

| Product Name | Silver Sublimation Sheet |

| Primary Use | Creating vibrant, durable, and high-definition prints with a metallic silver finish using the sublimation heat transfer process. |

| Key Benefits | – Unmatched vibrancy and color reproduction. – Exceptional durability (scratch, fade, and water-resistant). – Unique metallic aesthetic. – Professional and high-end results. – Versatile for various applications. |

| Target Audience | Artists, photographers, businesses, gift manufacturers, sign makers, interior designers, and anyone seeking premium, long-lasting prints with a distinct metallic look. |

| SEO Keywords | silver sublimation sheets, sublimation metal blanks, metallic photo panels, custom silver prints, durable sublimation sheets, high-quality silver sublimation |

Classification of Silver Sublimation Sheets

Silver sublimation sheets are available in various finishes to suit diverse aesthetic requirements.

| Classification Type | Description | Ideal Applications |

|---|---|---|

| Glossy Silver Sublimation | Highly reflective, shiny surface, enhancing color vibrancy and depth. | Photographs, vivid graphic designs, awards, decorative panels requiring maximum pop. |

| Matte Silver Sublimation | Subtle, non-reflective finish, reducing glare and providing an elegant look. | Artistic prints, signage in bright environments, understated awards, modern decor. |

| Brushed Silver Sublimation | Textured, linear brushed metallic appearance, adding sophistication. | High-end awards, contemporary signage, decorative panels, industrial-chic designs. |

| Adhesive Silver Sublimation | Features an adhesive backing for easy application after printing. | Labels, decals, custom stickers, flexible signage, product branding. |

Thickness Options for Silver Sublimation Sheets

The thickness impacts the rigidity, weight, and feel of the silver sublimation sheet.

| Thickness (mm) | Thickness (inches) | Characteristics | Common Applications |

|---|---|---|---|

| 0.3mm | ~0.012″ | Very flexible, lightweight. | Name tags, lightweight labels, decorative overlays. |

| 0.5mm | ~0.020″ | Flexible, still lightweight. | Smaller signs, thin photo panels, custom cards. |

| 0.8mm | ~0.031″ | Standard, balanced durability and flexibility, very common. | Photo panels, awards, medium-sized signage. |

| 1.0mm | ~0.039″ | Good rigidity, substantial feel. | High-quality photo panels, durable awards, robust signage. |

| 1.2mm | ~0.047″ | High rigidity, premium feel. | Larger display panels, high-end awards, custom architectural elements. |

| 1.5mm | ~0.059″ | Maximum rigidity, very premium, heavy-duty applications. | Large format displays, heavy-duty signage, industrial panels. |

Types

| Feature | Mirror Silver Sublimation Sheet | Brushed Silver Sublimation Sheet |

|---|---|---|

| Surface Finish | High-gloss, mirror-like reflection | Linear brushed pattern, satin-like texture |

| Visual Effect | Ultra-reflective, vibrant metallic shine | Soft muted shine, hides fingerprints and scratches |

| Best For | Luxury displays, jewelry packaging, high-end promotions | Modern decor, industrial designs, professional signage |

| Light Reflection | Strong and direct | Diffused and subtle |

| Durability | Shows fingerprints easily; requires careful handling | Fingerprint-resistant; more forgiving with daily use |

| Sublimation Result | Colors appear bright and vivid with metallic effect | Colors retain depth with a sophisticated matte metallic look |

| Common Applications | Premium retail displays, festive decorations, gift items | Office decor, appliance panels, tech accessories |

| Recommended Thickness | 0.8mm – 1.5mm for flexibility and reflectivity | 1.0mm – 2.0mm for enhanced durability and texture |

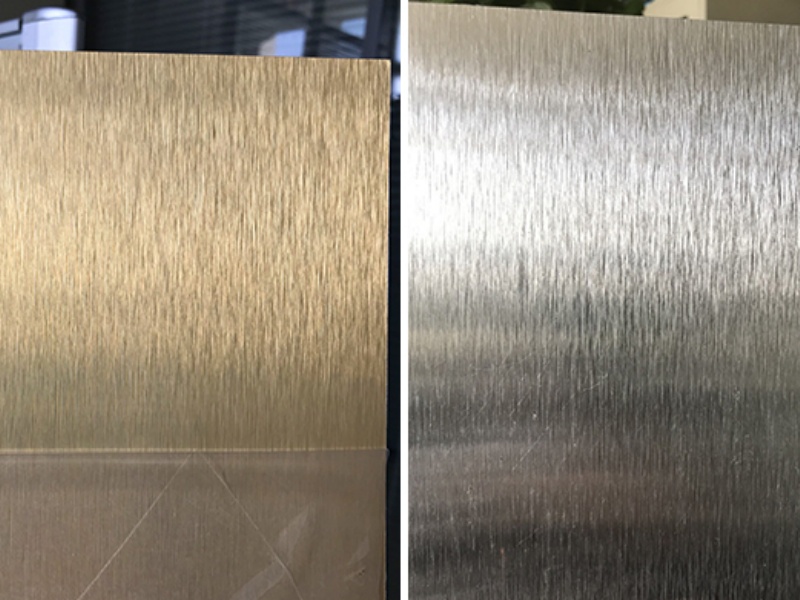

Mirror Silver

Brushed Silver

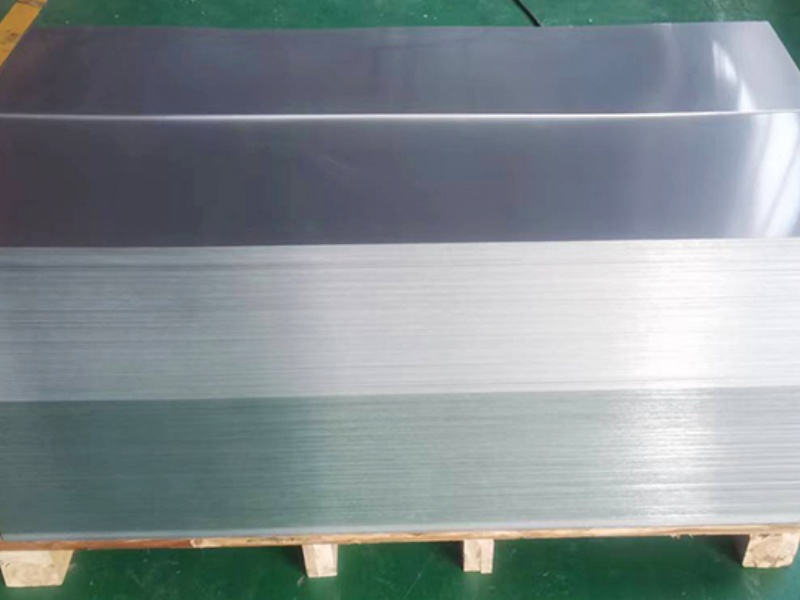

Alloy Composition of Silver Sublimation Sheets

Silver sublimation sheets are typically made from specific aluminum alloys chosen for their suitability for sublimation.

| Component | Details | Benefits for Sublimation Sheets |

|---|---|---|

| Base Material | Aluminum Alloy (e.g., 1100 Series, 3003 Series) | Lightweight, excellent corrosion resistance, good formability, durable. |

| Color | Silver (refers to metallic appearance, not actual silver content) | Provides a premium, reflective base for vibrant prints. |

| Coating | Specialized Polymer Sublimation Coating | Essential for accepting and embedding sublimation inks, ensuring vivid and permanent prints. |

| Properties | Lightweight, corrosion-resistant, durable, excellent adhesion for sublimation coating, heat-tolerant for the printing process. | Ensures product longevity, ease of handling, and high-quality print results. |

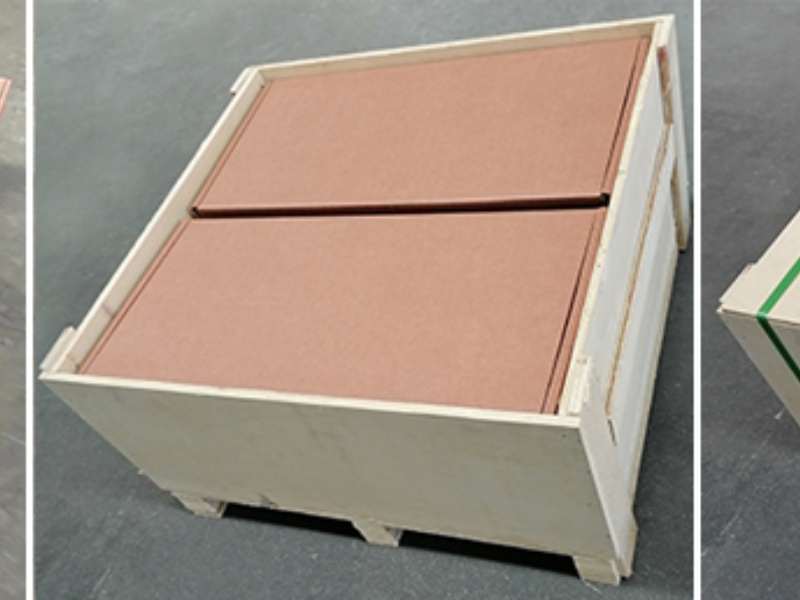

Packaging for Silver Sublimation Sheets

Proper packaging is crucial to protect your silver sublimation sheets from damage.

| Packaging Aspect | Description | Purpose |

|---|---|---|

| Protective Film | Clear or colored film applied to the printable (sublimation coated) side of each sheet. | Prevents scratches, dust, and minor surface damage during manufacturing, transport, and storage. Must be removed before sublimation. |

| Interleaving | Paper or foam sheets placed between individual sublimation sheets when stacked. | Prevents friction, scuffing, and sticking between sheets, especially in humid conditions or during temperature fluctuations. |

| Inner Packaging | Smaller bundles of sheets often wrapped in plastic or placed in individual protective sleeves. | Provides an additional layer of protection against moisture and dust for smaller quantities or during internal handling within a facility. |

| Outer Packaging | Sturdy, reinforced cardboard cartons or boxes. | Protects against physical impact, bending, and creasing during shipping and handling. Ensures the integrity of the silver sublimation sheets until they reach the end-user. |

| Palletization | For large orders, boxes are stacked on pallets and shrink-wrapped. | Offers maximum stability and protection for bulk shipments, reducing the risk of damage during freight transport and making handling more efficient. |

Application Areas for Silver Sublimation Sheets

The versatility of silver sublimation sheets makes them suitable for a wide range of creative and commercial uses.

- Personalized Photo Panels: Create stunning, durable photo displays with a metallic luster.

- Custom Awards & Trophies: Design unique recognition items that stand out.

- Decorative Wall Art: Produce modern and elegant art pieces for homes, offices, and galleries.

- Business & Retail Signage: Make durable, high-impact indoor and outdoor signs.

- Directional & Informational Panels: Ideal for public spaces, corporate environments, and museums.

- Personalized Gifts: Craft special items like coasters, keychains, and decorative plaques.

- Jewelry Components: Create custom pendants, earrings, and other small accessories.

- Machine Tags & Industrial Labels: Durable and legible identification for equipment and assets.

- Architectural Elements: Custom decorative panels for interior design.

Specifications

Here’s a detailed breakdown of common technical specifications for high-quality silver sublimation sheet:

| Feature | Common Specifications | Notes |

|---|---|---|

| Material | High-quality Aluminum Alloy (e.g., 1100, 3003 series) | Lightweight, durable, and corrosion-resistant metal. |

| Finish Options | Glossy, Matte, Brushed | Choose based on desired aesthetic (shiny, subtle, textured). |

| Standard Thicknesses | 0.3mm, 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm | Ranges from flexible to highly rigid, affecting application and feel. |

| Standard Sizes | A4 (210x297mm), A3 (297x420mm), 8.5×11 inches, 12×18 inches, 24×36 inches | Available in various pre-cut sizes for convenience and common applications. |

| Custom Sizes | Available upon request from manufacturers/suppliers. | Allows for tailored solutions to fit specific project dimensions. |

| Sublimation Coating | Proprietary Polymer Coating (one-sided) | Specifically designed for optimal ink absorption and vibrant, permanent transfers. |

| Protective Film | Yes, applied to the coated (printable) side. | Must be carefully peeled off before the sublimation process. |

| Heat Resistance | Designed to withstand standard sublimation temperatures (approx. 180-200°C / 355-395°F) | Ensures the sheet remains stable and the coating functions correctly under heat. |

| UV Resistance | Good, especially with high-quality coatings. | Helps prevent printed images from fading due to sun exposure. |

| Scratch Resistance | High (after sublimation process). | Sublimated images are embedded, offering superior durability against abrasion. |

Why Choose Silver Sublimation Sheets for Your Projects?

Choosing silver sublimation sheets means choosing quality and longevity.

- Unmatched Vibrancy: The special coating on these sheets allows for incredibly bright and vivid colors.

- Exceptional Durability: Sublimated prints are embedded into the coating, making them resistant to scratches, fading, and water. Your designs will last for years.

- Unique Metallic Finish: The silver base adds a sophisticated and premium look that ordinary paper or vinyl prints cannot replicate.

- Professional Results: Achieve high-definition prints that look polished and professional every time.

- Ease of Use: With the right sublimation equipment, printing on these sheets is a straightforward process, opening up a world of creative possibilities.

Conclusion

Silver sublimation sheets are an excellent choice for anyone looking to create durable, high-quality, and visually stunning prints with a unique metallic appeal. Whether for personalized gifts, professional signage, or artistic endeavors, these sheets offer a fantastic solution. Explore the possibilities and elevate your creations with the shine and longevity that only silver sublimation sheets can provide!