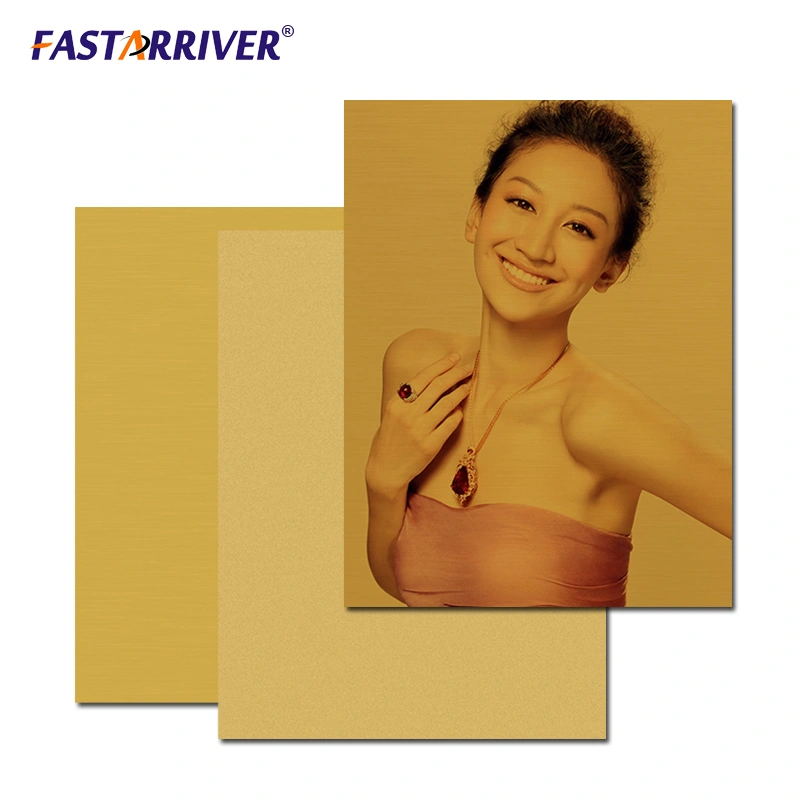

What are Pearlized White Sublimation Sheets?

A pearlized white sublimation sheet for photo printing is designed for creating high-quality images with a bright and elegant finish. The pearl effect gives photos a premium look, making them perfect for decorative panels, signage, and personalized gifts.

Iridescent pearl effect that enhances image depth

Brilliant white background for vibrant colors

Professional glossy finish without glare

Durable scratch-resistant surface

Key Specifications

| Parameter | Specification | Note |

|---|---|---|

| Base Material | High-grade aluminum | 0.8mm thickness |

| Coating Type | Pearlized polymer | Sublimation-ready |

| Surface Finish | Semi-gloss pearl | Non-reflective |

| Sheet Sizes | 8×10″, 11×14″, 16×20″ | Custom available |

Printing Performance

| Feature | Performance | Benefit |

|---|---|---|

| Color Reproduction | 98% sRGB gamut | Vibrant, accurate colors |

| Image Resolution | Up to 1440 dpi | Photographic quality |

| White Point | 95% reflectance | Bright background |

| Durability | Scratch-resistant | Long-lasting prints |

Sublimation Requirements

| Parameter | Setting | Importance |

|---|---|---|

| Temperature | 190°C (374°F) | Critical for transfer |

| Time | 60-75 seconds | Prevents under/over pressing |

| Pressure | Medium firm | Even image transfer |

| Cooling | 2 minutes | Sets image permanently |

Available Sizes & Prices

| Size | Price per Sheet | Box of 25 | Best For |

|---|---|---|---|

| 8×10″ | $3.50 | $75.00 | Standard photos |

| 11×14″ | $5.25 | $115.00 | Larger displays |

| 16×20″ | $8.75 | $195.00 | Professional prints |

| 24×36″ | $18.50 | $425.00 | Extra large formats |

Applications & Uses

Professional Photography:

- Studio portraits

- Wedding albums

- Senior photos

- Pet portraits

Art & Decor:

- Gallery prints

- Home decor

- Office artwork

- Hotel room art

Special Events:

- Wedding gifts

- Anniversary presents

- Graduation memorabilia

- Family reunions

Commercial Use:

- Restaurant decor

- Retail displays

- Trade show graphics

- Corporate awards

Comparison vs Regular Sheets

| Feature | Pearlized White | Regular White |

|---|---|---|

| Appearance | Iridescent pearl effect | Flat white |

| Color Depth | Enhanced 3D effect | Standard |

| Price | 20-30% premium | Base price |

| Market Appeal | Premium product | Standard product |

Design Tips for Best Results

Image Preparation:

- Use 300 DPI resolution

- Add 1/8″ bleed area

- Convert to CMYK color mode

- Enhance contrast slightly

Pressing Tips:

- Use protective paper

- Ensure even pressure

- Pre-press to remove moisture

- Allow proper cooling time

Handling:

- Wear cotton gloves

- Handle by edges only

- Store flat in cool place

- Avoid surface contact

Quality Assurance

Testing Performed:

- Coating adhesion tests

- Color fastness testing

- Scratch resistance tests

- Sublimation efficiency

Certifications:

- FDA compliant for safety

- ROHS environmental standard

- ISO 9001 quality management

- Material safety data sheets

Packaging Options

| Package | Sheets | Protection | Price |

|---|---|---|---|

| Standard | 10 | Cardboard sleeves | $35.00 |

| Professional | 25 | Foam separation | $80.00 |

| Bulk | 100 | Wooden crate | $300.00 |

| Sample Pack | 3 | Rigid mailer | $12.00 |

FAQ

Q: How does pearlized differ from metallic?

A: Pearlized has soft iridescence while metallic has stronger sparkle

Q: Can I use these for outdoor displays?

A: Not recommended unless laminated for UV protection

Q: What printer settings work best?

A: Use high quality setting with ICC profile for pearlized surfaces

Q: How long do prints last?

A: 50+ years indoors with proper care

Q: Are they recyclable?

A: Yes, aluminum is 100% recyclable

Where to Buy Quality Pearlized Sheets

Reputable brands like Koala Paper, A-Sub, and Neenah offer acid-free, warp-resistant options. Look for:

- ISO 9001 certification (quality control)

- Fast-drying coatings (reduces ink smudging)

- Static-free packaging

How to Use Pearlized Sublimation Sheets (3 Simple Steps)

- Print: Mirror your photo design onto the sheet using sublimation ink.

- Press: Use a heat press (190°C/375°F for 45-60 seconds).

- Peel: Remove the sheet while hot for a crisp finish.

Pro Tip: Always pre-press substrates for 5-10 seconds to remove moisture!

5 Tips for Flawless Pearlized Photo Prints

- Use high-resolution images (300 DPI minimum) to avoid pixelation.

- Store sheets flat in sealed bags to prevent humidity damage.

- Test press time/temperature on a small area first—pearl coatings vary by brand.

- For dark fabrics, choose white-backed sheets to block substrate bleed-through.

- Pair with dye-sublimation ink only (other inks won’t transfer correctly).

Pearlized vs. Regular White Sublimation Sheets

| Feature | Pearlized White | Regular White |

|---|---|---|

| Finish | Shimmering, metallic glow | Matte/semi-gloss |

| Color Vibrancy | ★★★★★ | ★★★☆☆ |

| Durability | Scratch-resistant | Prone to wear |

| Ideal Use | Premium gifts, décor | Basic transfers |

| Price | 10-15% higher | Budget-friendly |