Have you ever seen a vibrant, full-color image perfectly printed on a mug, t-shirt, or metal panel and wondered, “How do they do that?” The answer often lies in the magical world of sublimation printing, and the stars of this show are sublimation blanks. If you’re looking to create your own personalized items, understanding how to use sublimation blanks is your first step into a world of creativity.

How to Use Sublimation Blanks: A Step-by-Step Guide

Learning how to print on sublimation blanks is a straightforward process once you understand the basic steps. Follow this guide to turn your designs into reality.

1: Design Your Image

- Software: Use graphic design software (like Adobe Photoshop, Illustrator, Canva, or CorelDRAW) to create or edit your design.

- Quality: Ensure your image is high-resolution for the best print quality.

- Mirror Image: Crucially, you must mirror (flip horizontally) your image before printing. If you don’t, your design will appear backward on the finished product.

2: Print Your Design

- Sublimation Printer: You need a dedicated sublimation printer. Regular inkjet printers won’t work as they don’t use sublimation ink.

- Sublimation Ink: Fill your printer with specialized sublimation ink. These inks are formulated to turn into a gas when heated.

- Sublimation Paper: Print your mirrored design onto sublimation paper. This paper is designed to release the ink cleanly under heat and pressure. Do not use regular copy paper.

3: Prepare Your Sublimation Blank

- Clean the Blank: Before placing your design, ensure your sublimation blank is clean and free of dust, lint, or fingerprints. A lint roller for fabric or a clean cloth for hard surfaces works best.

- Positioning: Place your printed sublimation paper face down onto the sublimation blank. Make sure the design is centered and positioned exactly where you want it.

- Secure with Tape: Use heat-resistant tape to firmly secure the sublimation paper to the blank. This prevents the paper from shifting during the heat press process, which can cause “ghosting” (a blurry double image).

- Protect Your Press: Place a sheet of butcher paper or protective paper on the bottom platen of your heat press. This catches any excess ink that might bleed through and protects your press from stains. You might also want a sheet on top of your design.

4: Heat Press the Blank

This is where the magic happens! You’ll need a heat press suitable for your blank type (e.g., a flat press for t-shirts, a mug press for mugs).

- Settings: Each type of sublimation blank requires specific temperature, time, and pressure settings. Always refer to the manufacturer’s recommendations for your specific blank and ink.Blank TypeAvg. TemperatureAvg. TimeAvg. PressureT-shirts (Polyester)385−400∘F (195−205∘C)45−60 secondsMedium-FirmCeramic Mugs400∘F (205∘C)180−240 secondsMedium-FirmAluminum Panels400∘F (205∘C)45−60 secondsMediumKeychains (MDF)400∘F (205∘C)60−80 secondsMedium-Firm

- Pressing: Carefully place the prepared blank (with the design taped to it) into the heat press. Close the press. The heat and pressure will cause the solid sublimation ink to turn into a gas, which then infuses into the polyester coating of your blank.

- Ventilation: Ensure you have good ventilation in your workspace, as some fumes can be released during pressing.

Step 5: Finish and Reveal

- Careful Removal: Once the timer goes off, open the heat press. Carefully remove the blank and the paper. Hard blanks will be very hot! Use heat-resistant gloves.

- Peel Paper: Immediately and carefully peel the sublimation paper away from the blank.

- Cool Down: Allow the finished product to cool completely. As it cools, the gaseous ink solidifies within the blank’s coating, making the print permanent.

Essential Equipment for Sublimation Printing

To successfully print on sublimation blanks, you’ll need a few key pieces of equipment:

- Sublimation Printer: A printer specifically designed for sublimation, loaded with sublimation inks.

- Sublimation Inks: Special dyes that turn into a gas when heated.

- Sublimation Paper: Designed to hold and then release the ink efficiently.

- Heat Press: This is the most crucial tool, applying the necessary heat and pressure. Types include:

- Flat Press: For t-shirts, metal panels, tiles, etc.

- Mug Press: For cylindrical items like mugs and tumblers.

- Cap Press: For hats.

- Multi-Function Press: Combines several platens.

- Heat-Resistant Tape: To secure your design to the blank.

- Butcher Paper (or Blowout Paper): To protect your heat press from ink transfer.

- Heat-Resistant Gloves: Essential for handling hot blanks.

- Lint Roller / Cleaning Cloth: To ensure blanks are clean.

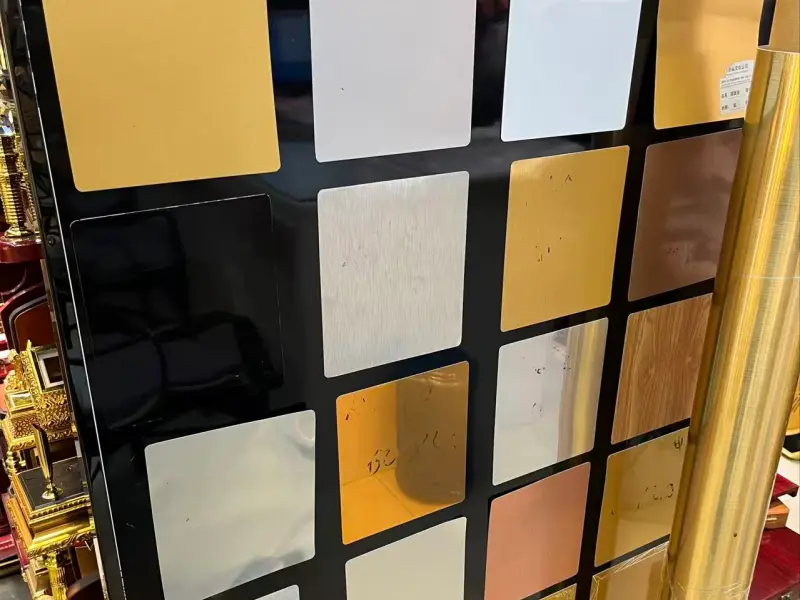

Can I Make My Own Sublimation Blanks?

This is a common question, especially for those interested in DIY projects. While it is theoretically possible to create your own sublimation blanks by applying a polymer coating to untreated items, it comes with significant challenges:

- Special Coatings: You would need to source specific liquid or spray-on polymer coatings designed for sublimation.

- Application Difficulty: Achieving an even, consistent, and smooth coating without bubbles, dust, or drips is very difficult without specialized equipment. Any imperfections will show on your final print.

- Curing Process: These coatings often require a precise curing process (baking at specific temperatures for a certain duration) to bond properly and be ready for sublimation.

- Quality & Durability: Commercially manufactured sublimation blanks undergo rigorous quality control to ensure proper adhesion, vibrant color reproduction, and durability. Replicating this at home is tough.

For reliable, high-quality results, especially when starting out, purchasing pre-coated sublimation blanks is highly recommended. It saves time, effort, and ensures your finished products look professional.

Tips for Success When Printing on Sublimation Blanks

- Pre-press Fabric Blanks: If sublimating on fabric like a t-shirt, pre-press it for a few seconds to remove moisture and wrinkles.

- Use Proper Pressure: Too little pressure can lead to faded prints; too much can damage the blank or press.

- “Ghosting” Prevention: Always tape your design securely, especially for hard goods.

- Ventilation: Work in a well-ventilated area to dissipate fumes.

- Test Prints: If using a new blank or design, do a small test print first.

- Avoid Over-pressing: Too much heat or time can cause colors to become dull or burnt.

how to use sublimation blanks

Now you know how to use sublimation blanks to create custom products with incredible detail and lasting vibrancy. From selecting the right sublimation blank and preparing your design to mastering the heat press process, each step contributes to a successful outcome. While making your own sublimation blanks is challenging, the wide variety of pre-made blanks available makes it easy for anyone to dive into this rewarding craft. So gather your supplies, fire up your press, and start transforming ordinary items into extraordinary personalized treasures!

Leave a Reply

You must be logged in to post a comment.