Dye Sub Aluminum Sheet

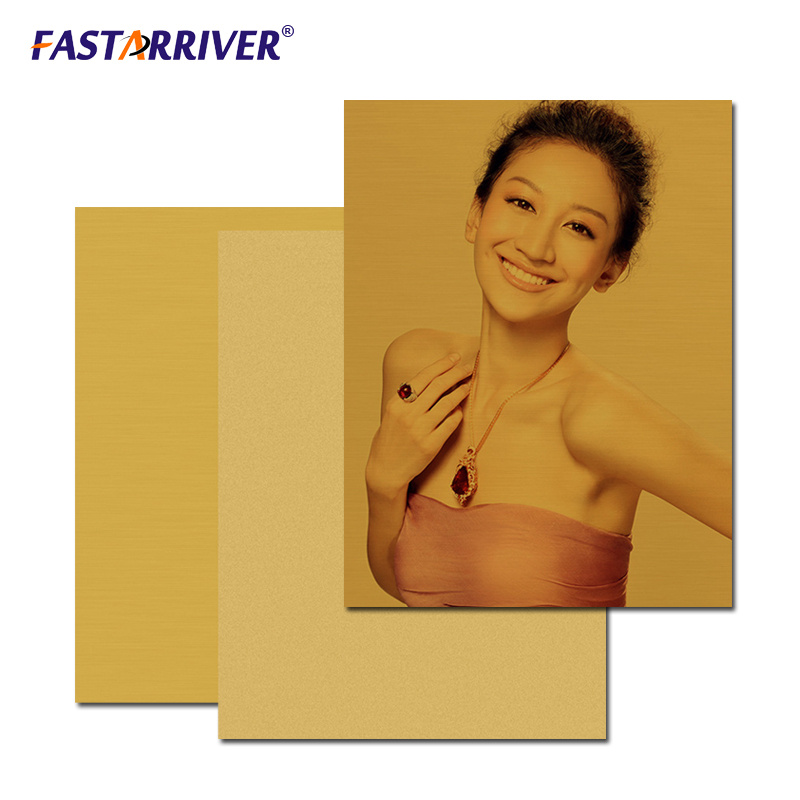

Dye sublimation aluminum sheets, also known as sublimation aluminum sheets, always use bright color varnish to coating it, always use it for dye sublimation printing. These sheets have a polyester coating that allows the sublimation ink to bond with the surface when heat and pressure are applied during the printing process, if you are interested in our products or have any question about out company’s products, please contact us.

Specification

| Colors | Thickness | Length and Width |

| High gloss white, Matt white, Matt gold Matte silver, bright gold, bright silver | 0.25 | Common specification and Customized |

| 0.35 | ||

| 0.45 | ||

| 0.65 | ||

| 1.00 | ||

| Pearlescent gold, silver, white | 0.25 | |

| 0.35 | ||

| 0.45 | ||

| 0.65 | ||

| 1.00 | ||

| Mirror gold, silver, light gold | 0.45 | |

| Brushed gold, silver, bronze | 0.35 | |

| 0.45 | ||

| 0.65 |

Characteristics

Characteristics

1. Durable: very durable, not easy to scratch, fade and corrosion, suitable for outdoor and high traffic areas.

2. Vivid Color: Vivid, high-definition colors can be transferred onto the aluminum panels to create eye-catching, detailed prints.

3. Lightweight: Lightweight for easy handling and transportation while maintaining a strong, rigid structure.

4. Weather Resistant: Weather resistant, making it suitable for outdoor signage, displays and other applications that require long term durability in all weather conditions.

Applications

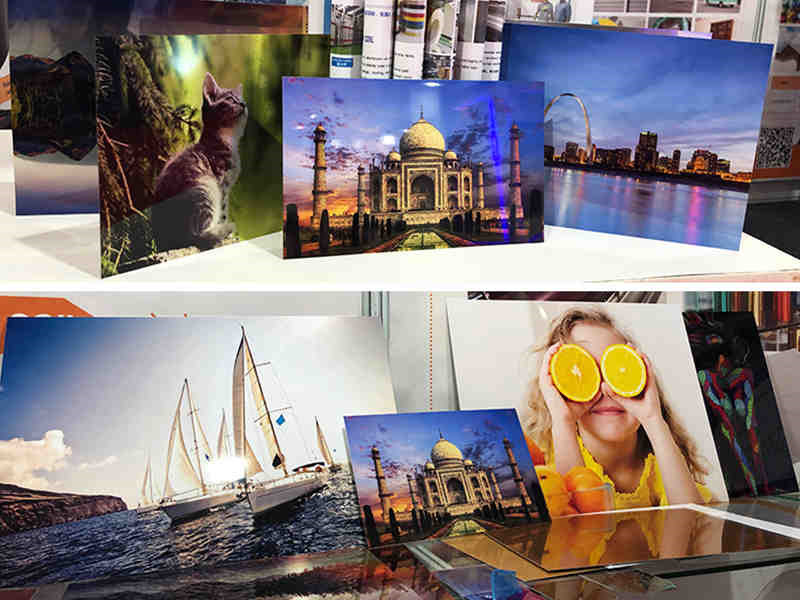

1. Photography: Dyed sub aluminum sheet are popular for producing high-quality photo prints with a glossy finish, ideal for photographers who want to display their work in a unique and durable way.

2. Home Decor: Use it to create customized home decoration items such as murals, photo boards, coasters, and ornaments to add a personalized touch to any space.

3. Awards and trophies: Commonly use it to create custom awards, plaques, and trophies due to their professional appearance and ability to showcase intricate designs and logos.

Home Decoration of Dye sub aluminum sheet

Dye sublimation aluminum sheets for home decoration: such as wall decoration, furniture surface decoration, etc. Through heat transfer technology, various patterns, images, text, etc. can be printed onto the plate, adding personal and art to the home environment. It is also commonly used in DIY handicrafts production, you can make personalized gifts, decorations, etc, to meet the needs of personal creativity and decoration. Can achieve high definition, rich color printing effect, make the decorative effect more vivid.

Production process

1. Prepare the design: Design the desired pattern or image and convert it to digital format for printing on the thermal transfer plate.

2. Printing the design: Using a specialized thermal transfer printer and ink. These inks are special acrylic inks that transfer to the target surface when heat.

3. Prepare the substrate: Prepare the substrate to transfer it. Make sure the surface of the substrate is clean and flat to ensure the heat transfer effect.

4. Heat transfer: Align the heat transfer paper with the surface of the substrate and then transfer the design onto the substrate by means of a heat press or heat transfer machine. Under high temperature and pressure. Ink will transfer from the heat transfer paper to the surface of the substrate to form a pattern or image.

5. Cooling and curing: After completing the heat transfer, allow the substrate to cool and cure. It ensures that the design is firmly adhered to the substrate surface.