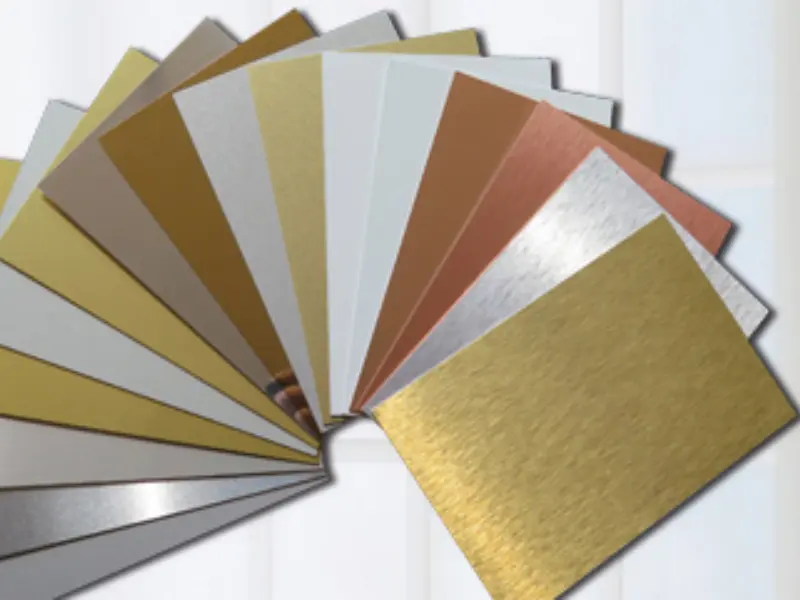

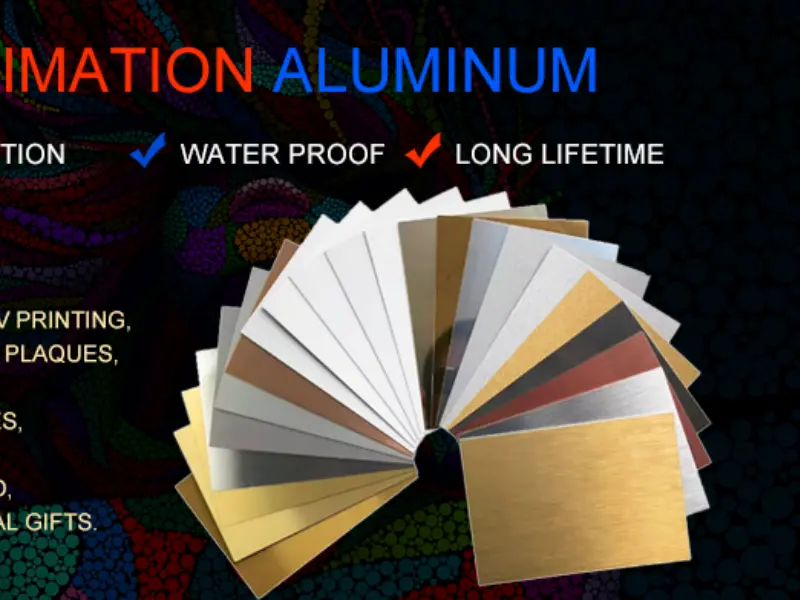

A brushed aluminum sublimation sheet is an excellent choice for both decorative and professional printing. With its metallic brushed effect, it creates premium, long-lasting products. Buyers can choose from different classifications, thicknesses, alloys, and packaging options to fit their needs.

If you are looking for reliable brushed sublimation sheets, contact us, your trusted aluminum sheet manufacturer.

Classification of Brushed Aluminum Sheets

| Type | Brush Pattern | Best For |

|---|---|---|

| Fine Brushed | Subtle, tight lines | Elegant decor, premium products |

| Medium Brushed | Visible linear grain | General signage, displays |

| Coarse Brushed | Bold, deep lines | Industrial look, architectural |

| Patterned Brushed | Decorative designs | Artistic applications, features |

Thickness Options

| Thickness (mm) | Weight (g/m²) | Rigidity Level | Recommended Applications |

|---|---|---|---|

| 0.8 | 216 | Flexible | Photo panels, small decor |

| 1.0 | 270 | Medium | Signage, retail displays |

| 1.5 | 405 | High | Partitions, exhibition graphics |

| 2.0 | 540 | Very High | Architectural elements, durable signs |

Aluminum Alloy Base

| Alloy | Properties | Best For |

|---|---|---|

| 1050 | Soft, excellent brushing | Decorative items, gift products |

| 3003 | Good strength, formability | General purpose applications |

| 5052 | Excellent corrosion resistance | Outdoor or humid environments |

Packaging Standards

Professional packaging includes:

- Protective film on brushed surface

- Foam separators between sheets

- Reinforced corner protectors

- Weather-resistant outer wrapping

- Custom packaging options available

Standard packaging quantities:

- 25 sheets/box (0.8-1.0mm)

- 20 sheets/box (1.5mm)

- 15 sheets/box (2.0mm)

Key Features and Benefits

Fingerprint Resistance: Hides smudges and marks effectively

Reduced Glare: Matte finish minimizes light reflection

Enhanced Grip: Textured surface improves handling

Professional Appearance: Sophisticated industrial aesthetic

Durable Surface: Resists scratches and wear

Applications

- Home and Office Decor

- Modern wall art

- Desk organizers

- Nameplates and signs

- Retail and Display

- Point-of-sale signage

- Product showcases

- Exhibition graphics

- Industrial Design

- Machine panels

- Equipment nameplates

- Control panels

- Personalized Products

- Custom gifts

- Awards and trophies

- Memorial plaques

- Architectural Elements

- Feature walls

- Door plaques

- Directional signage

Technical Specifications

| Parameter | Specification | Test Standard |

|---|---|---|

| Surface Roughness | 0.3-0.8 μm | ISO 4287 |

| Brush Line Depth | 0.1-0.3 mm | Visual comparison |

| Sublimation Temp | 180-200°C | – |

| Sublimation Time | 45-60 seconds | – |

Printing Guidelines

- Design Preparation

- Consider brush direction in layout

- Use high-contrast designs

- Mirror image before printing

- Printing Process

- Use sublimation ink only

- Ensure proper ink coverage

- Allow adequate drying time

- Heat Press Settings

- Temperature: 185-195°C

- Time: 50-60 seconds

- Pressure: Medium consistent

- Post-Processing

- Cool completely before handling

- Remove protective film carefully

- Inspect for uniform transfer

Comparison: Brushed vs Plain Sheets

| Feature | Brushed Sheets | Plain Sheets |

|---|---|---|

| Surface Texture | Linear grain pattern | Smooth, uniform |

| Glare Reduction | Excellent | Minimal |

| Fingerprint Hide | Very good | Shows marks easily |

| Visual Appeal | Industrial, sophisticated | Clean, modern |

| Cost | Slightly higher | Lower |

Maintenance and Care

- Cleaning

- Use soft cloth and mild detergent

- Wipe along brush grain direction

- Avoid abrasive cleaners

- Storage

- Store in dry, flat position

- Keep protective film on until use

- Avoid stacking heavy items

- Handling

- Wear gloves to prevent oils

- Support large sheets properly

- Handle edges carefully

What is a Brushed Aluminum Sublimation Sheet?

A brushed aluminum sublimation sheet is a specialized metal substrate with a distinctive linear textured surface, created by brushing the aluminum with abrasive materials. This unique finish reduces glare, hides fingerprints, and provides a sophisticated matte metallic appearance that enhances the visual appeal of sublimated designs.

FAQ

Q: Can brushed sheets be used outdoors?

A: Yes, especially 5052 alloy sheets with proper protective coating.

Q: How does brushing affect print quality?

A: The texture adds depth to designs but may slightly soften fine details.

Q: Are these sheets recyclable?

A: Yes, aluminum is fully recyclable.

Q: Can I request custom brush patterns?

A: Yes, many suppliers offer custom brushing patterns.

Conclusion

Brushed aluminum sublimation sheets offer a unique combination of functionality and aesthetic appeal. Their distinctive textured surface provides practical benefits like fingerprint resistance and reduced glare while creating a sophisticated industrial look that enhances various applications.

When selecting brushed aluminum sheets:

✔ Choose the appropriate brush pattern for your design

✔ Select the right thickness for your application

✔ Consider the alloy based on usage environment

✔ Follow recommended printing guidelines

✔ Handle and maintain properly for longevity

Whether creating modern decor, professional signage, or industrial components, brushed aluminum sublimation sheets provide a durable and visually appealing substrate that elevates the quality and appearance of your finished products.