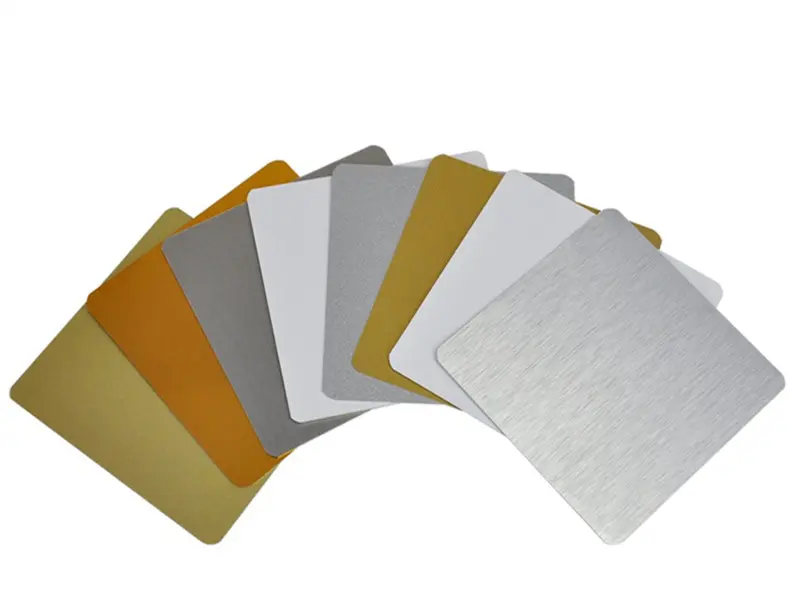

Brushed Aluminum Sheet for Sublimation is a popular decorative metal material known for its clean linear texture and modern appearance. It is widely used in architecture, interior decoration, appliances, signage, and industrial equipment. Compared with mill finish aluminum, brushed aluminum sheets offer a more refined surface while keeping excellent corrosion resistance and light weight.

With different alloys, thicknesses, and surface patterns available, brushed aluminum sheet metal is an ideal choice for both functional and aesthetic applications.

Brushed Aluminum Sheet Surface Finish

Common Brushed Finishes

| Finish Type | Description | Typical Applications |

|---|---|---|

| Hairline finish | Fine straight lines | Wall panels |

| Long grain | Long continuous texture | Elevators |

| Short grain | Short brushed pattern | Appliances |

| Cross brushed | Cross-direction texture | Decorative panels |

The brushing direction can be customized according to installation requirements.

Aluminum Alloys for Brushed Aluminum Sheets

Different aluminum alloys provide different strength, formability, and surface performance.

| Alloy | Temper | Features |

|---|---|---|

| 1050 / 1060 | O / H14 | High purity, excellent brushing effect |

| 3003 | H14 | Good corrosion resistance |

| 5005 | H34 | Ideal for anodizing |

| 5052 | H32 | Higher strength and durability |

Among them, 3003 and 5005 brushed aluminum sheets are the most commonly used for decorative projects.

Standard Thickness and Sizes

| Thickness (mm) | Common Sheet Sizes |

|---|---|

| 0.5 – 1.0 | 1000 × 2000 mm |

| 1.2 – 2.0 | 1220 × 2440 mm |

| 2.5 – 3.0 | 1500 × 3000 mm |

| Custom | Cut-to-size available |

Thickness tolerance and grain direction can be controlled according to customer requirements.

Advantages of Brushed Aluminum Sheet Metal

- Lightweight and strong

- Elegant metallic appearance

- Uniform surface texture

- Excellent corrosion resistance

- Easy to fabricate and bend

- Suitable for anodizing and coating

- Long service life

- 100% recyclable

Disadvantages of Brushed Aluminum Sheets

- Scratches are visible along grain direction

- Not as reflective as mirror aluminum

- Grain direction must be consistent during installation

- Slightly higher cost than mill finish aluminum

Applications of Brushed Aluminum Sheet Metal

Brushed aluminum sheets are widely used in many industries:

- Architectural wall cladding

- Elevator cabin panels

- Ceiling decoration

- Kitchen backsplash panels

- Appliance housings

- Advertising signage

- Furniture panels

- Electronic enclosures

Brushed Aluminum Sheet vs Other Finishes

| Finish | Appearance | Cost | Typical Use |

|---|---|---|---|

| Mill finish | Raw aluminum | Low | Industrial |

| Brushed | Linear texture | Medium | Decoration |

| Anodized | Colored protection | High | Architecture |

| Mirror | Highly reflective | High | Luxury design |

Can Brushed Aluminum Be Anodized or Coated?

Yes. Brushed aluminum sheet metal can be:

- Clear anodized

- Black anodized

- Bronze anodized

- Powder coated

Brushing before anodizing creates a premium metallic appearance.

Packaging and Protection

- PVC protective film on surface

- Direction marking for grain

- Wooden pallet packing

- Suitable for sea and container transport

How to Choose the Right Brushed Aluminum Sheet

- Select suitable alloy

- Confirm thickness and tolerance

- Choose brushing pattern

- Determine indoor or outdoor use

- Decide anodized or raw surface

Frequently Asked Questions

Is brushed aluminum easy to scratch?

Minor scratches may appear along the grain direction, but proper protection reduces damage.

Can brushed aluminum be used outdoors?

Yes, especially when anodized or coated.

Which alloy is best for brushed aluminum sheets?

3003 and 5005 are most widely used.

Brushed Aluminum Sheet Metal Supplier

As a professional aluminum manufacturer, FASTARRIVER ALUMINUM supplies brushed aluminum sheet metal with:

- Multiple alloy options

- Stable brushing quality

- Custom sizes and thickness

- Export-standard packaging

- Factory-direct pricing

What Is Brushed Aluminum Sheet Metal?

Brushed aluminum sheet metal is produced by mechanically brushing the surface of aluminum sheets using abrasive belts or brushes. This process creates uniform straight or patterned lines on the surface.

The brushing treatment removes surface imperfections and gives aluminum a matte metallic texture that looks clean and professional.

Common names include:

- Brushed aluminum sheet

- Brushed aluminum plate

- Hairline aluminum sheet

Brushed Aluminum Sheet for Sublimation

Brushed aluminum sheet metal combines modern appearance, excellent performance, and wide application value. With various alloys, finishes, and sizes available, it is one of the most versatile aluminum materials for decorative and industrial projects.