As a leading manufacturer with over 15 years of expertise, we specialize in producing high-quality aluminium sheets for dye sublimation printing that guarantee vibrant, durable, and precise results. Our commitment to excellence, competitive pricing, and reliable customer partnerships make us the preferred choice for businesses worldwide.

What Are Aluminium Sheets for Dye Sublimation Printing?

Aluminium sheets for dye sublimation printing are special coated metal panels that allow high-resolution image transfer. They are widely used for photo panels, signage, awards, and decoration. With smooth coating and strong durability, sublimation aluminium sheets ensure long-lasting and vivid prints.

Product Specifications

| Classification | Thickness | Alloy | Packaging |

|---|---|---|---|

| Glossy White Aluminium Sheet | 0.45mm – 1.2mm | 1060 / 3003 | PE film, carton box, wooden pallet |

| Matte White Aluminium Sheet | 0.5mm – 1.0mm | 1100 / 3003 | Shrink film, carton, pallet |

| Silver Brushed Sublimation Sheet | 0.45mm – 1.2mm | 1050 / 5052 | Carton + protective film |

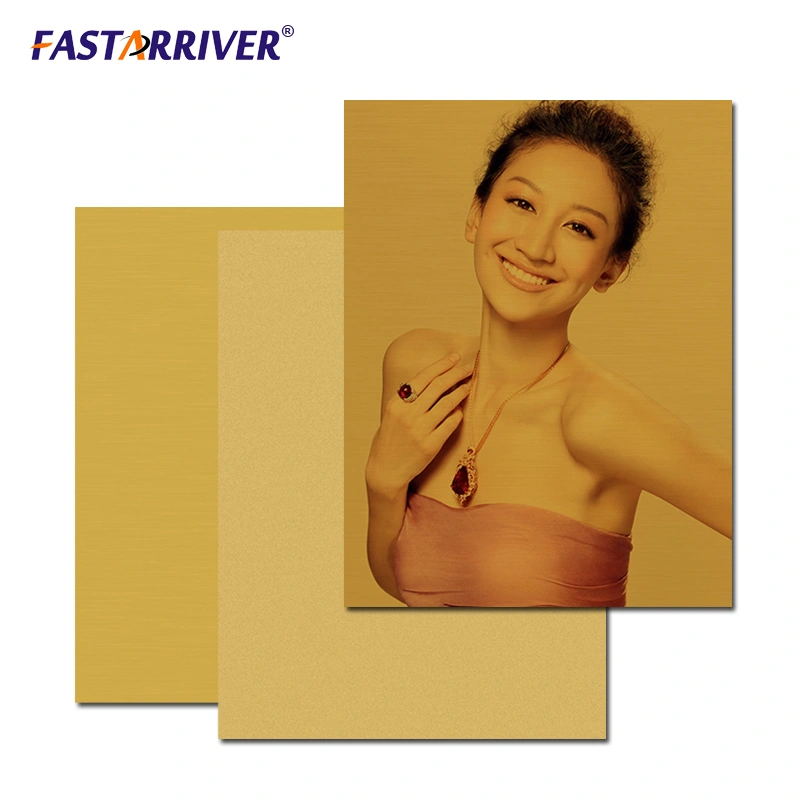

| Gold Brushed Sublimation Sheet | 0.5mm – 1.5mm | 1060 / 3003 | Export wooden pallet |

| Custom Size Aluminium Panel | 0.4mm – 1.5mm | 1100 / 5052 | According to customer request |

Why Choose Worthwill Aluminum?

Factory Direct Supply

- Own production lines for sublimation aluminium sheets.

- Strict quality control at every stage.

- Flexible customization in size, thickness, and coating.

Fast and Accurate Production

- Advanced coating equipment.

- Quick delivery time with efficient logistics.

- Consistent quality, minimal error rate.

Competitive and Reasonable Price

- Direct factory pricing without middleman cost.

- Stable raw material sourcing.

- Long-term cost advantage for bulk buyers.

Long Experience and Trust

- Over 15 years in aluminium production.

- Cooperation with global clients in printing and signage industry.

- Reliable supplier with long-term partnership reputation.

Applications of Aluminium Sheets for Sublimation

- Photo printing: family pictures, wall decoration, art displays.

- Signage: advertising boards, indoor & outdoor signs.

- Awards & plaques: trophies, certificates, recognition boards.

- Home decoration: custom panels, wall designs, creative artwork.

- Commercial use: shop display boards, company branding.

Comparison With Other Suppliers

| Factor | FASTARRIVER Aluminum | Other Suppliers |

|---|---|---|

| Price | Competitive factory-direct price | Higher with middlemen |

| Production | Fast and accurate | Often slower, less flexible |

| Experience | 15+ years | Limited in sublimation sheets |

| Reliability | Trusted by long-term partners | Not always stable |

| Customization | Wide range of options | Limited specifications |

Popular Aluminum Sublimation Sheet

- High-Quality Aluminium Sheets for Sublimation Printing

- Where to Buy Aluminium Sheets for Dye Sublimation?

- Factory Price Aluminium Sublimation Panels – FASTARRIVER Aluminum

- Custom Sizes of Aluminium Sublimation Sheets Available

- Best Supplier of Dye Sublimation Aluminium Panels in China

Conclusion

Aluminium sheets for dye sublimation printing are the best choice for creating durable, vivid, and professional prints. FASTARRIVER Aluminum provides customers with high-quality sheets, fast production, accurate specifications, and competitive prices. With years of experience and trust from international buyers, we are your reliable partner for sublimation printing materials.

The Right Alloy: Foundation of Our Quality Aluminium Sublimation Sheets

The core material of our aluminium sheets for dye sublimation printing is a high-grade aluminium alloy, chosen specifically for its flatness, consistent surface quality, and excellent resistance to corrosion. Common alloys we utilize include:

- 3003 Series Aluminium: Highly regarded for its strength, excellent workability, and good corrosion resistance, making it a reliable choice for sublimation.

- 1100 Series Aluminium: Known for its exceptional corrosion resistance and high ductility, ensuring a smooth, consistent base for the specialized coating.

Our careful selection of the alloy ensures that every sheet provides a stable and premium substrate for your vibrant, long-lasting prints.

Our Classification of Aluminium Sublimation Sheets

We pride ourselves on offering a diverse range of aluminium sheets for dye sublimation printing to meet every need. Our classification primarily focuses on the surface finish and the specific coating, ensuring you find the perfect match for your project.

- White Gloss Aluminium Sheets: The most popular choice, offering a bright white base that makes colors pop with brilliant intensity and a high-gloss finish for a reflective, premium look.

- White Matte Aluminium Sheets: Provides a sophisticated, non-reflective surface that minimizes glare, ideal for environments where reflections are a concern or for a more subdued artistic presentation.

- Clear Gloss Aluminium Sheets: Allows the natural metallic sheen of the aluminium to show through lighter areas of your design, adding a unique, translucent effect and a modern touch.

- Brushed Aluminium Sheets: Features a distinctive brushed texture beneath the clear coating, giving images a dynamic, metallic backdrop and a high-end feel. (Note: If you offer brushed, this can be combined or separated based on your exact product line).

Each type of aluminium sheet for dye sublimation printing is engineered for superior ink absorption and image clarity.

Precision Thickness: Choosing the Right Aluminium Sublimation Panel

The thickness of your aluminium sheets for dye sublimation printing impacts their rigidity, weight, and suitability for various applications. We offer several precise options:

- 0.5mm (0.020 inches): Lightweight and flexible, perfect for smaller items, decorative plaques, or where minimal weight is required. Easy to cut and handle.

- 0.7mm (0.028 inches): Our most popular thickness, striking an excellent balance between durability and manageability. Ideal for general signage, photo panels, and awards.

- 1.0mm (0.040 inches): Provides superior rigidity and a substantial feel, recommended for larger format signs, outdoor displays, and applications requiring extra strength and resistance to bending.

Selecting the correct thickness is key to the longevity and aesthetic of your final product.