Aluminum sublimation sheets are premium metal surfaces designed for heat transfer printing. They are coated with a special polyester layer, making them ideal for sublimation printing, producing bright, long-lasting images. These sheets are widely used for photo printing, promotional items, signage, and personalized gifts.

Benefits of aluminum sublimation sheet:

- Durable and scratch-resistant

- Smooth and flat surface for high-resolution printing

- Vibrant color reproduction

- Lightweight and easy to handle

- Suitable for indoor and outdoor applications

Types

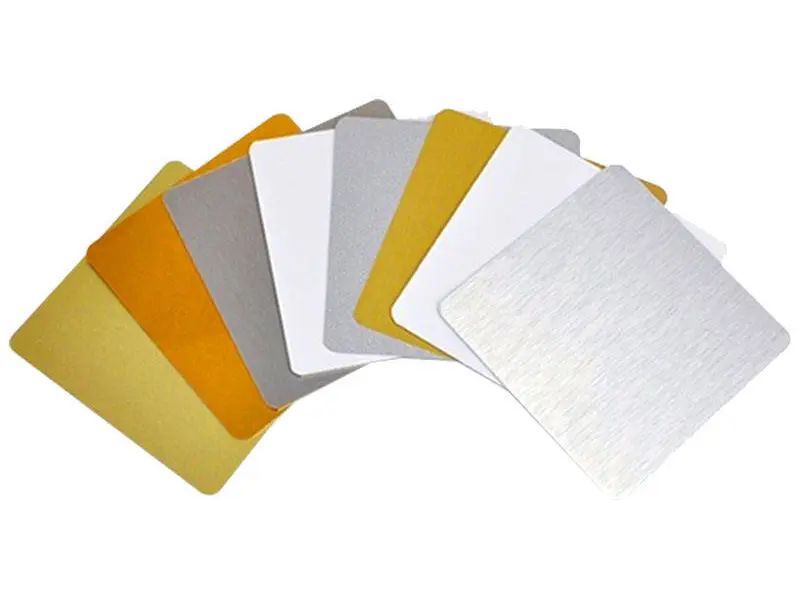

There are various types of sublimation sheets based on thickness, coating, and finish:

| Type | Thickness | Finish | Features |

|---|---|---|---|

| Standard Aluminum Sheet | 0.3 mm – 1 mm | Glossy | Single-sided sublimation coating |

| Double-Sided Aluminum Sheet | 0.5 mm – 1 mm | Matte/Glossy | Coated on both sides for versatile printing |

| Printable Aluminum Sheet | 0.3 mm – 2 mm | Glossy | Ready for dye sublimation or UV printing |

| Sublimation Steel Sheet | 0.5 mm – 1.5 mm | Matte | Strong, durable metal alternative |

These specifications help customers select the right type of aluminum or steel sheet for their projects.

Can You Sublimate on Aluminum?

Yes, you can sublimate on aluminum if it is coated with a polyester or sublimation-ready layer. Uncoated aluminum cannot hold sublimation inks, so using a pre-coated sheet is essential for bright and long-lasting results.

Key tips for sublimating on aluminum:

- Use high-quality sublimation inks

- Apply proper heat and pressure

- Ensure the surface is clean and dry

- Consider double-sided sheets for versatile designs

Applications

Aluminum sublimation sheet are highly versatile and commonly used in:

- Photo printing – personalized photo panels, wall art

- Promotional products – branded gifts, awards, plaques

- Signage – indoor and outdoor aluminum signs

- Crafts and DIY projects – custom metal prints, décor items

- Corporate gifts – recognition plaques, personalized awards

Advantages of Using Aluminum Sublimation Sheet

Choosing aluminum sublimation sheet offers several advantages:

- Long-lasting and durable prints

- High-resolution image quality

- Waterproof and scratch-resistant

- Lightweight and easy to cut or shape

- Suitable for full-color designs, logos, and photos

Common Sizes and Specifications

Aluminum sublimation sheet come in various sizes and thicknesses to meet different project requirements.

| Sheet Size | Thickness | Use Case |

|---|---|---|

| 4″ × 8″ | 0.3 mm | Small photo panels, gifts |

| 8″ × 12″ | 0.5 mm | Medium decorative prints |

| 12″ × 18″ | 0.8 mm | Wall décor, gallery prints |

| Custom Sizes | 0.3 – 2 mm | Commercial projects, signage |

Numeric specifications help designers and businesses select the right sheets for their sublimation projects.

How to Use Aluminum Sublimation Sheet

Proper preparation ensures high-quality prints:

- Preheat the heat press to the recommended temperature

- Align your design carefully on the coated sheet

- Apply consistent pressure during transfer

- Let the sheet cool before removing the protective paper

Following these steps produces vibrant, long-lasting results.

Double-Sided Sublimation Metal

Double-sided sublimation sheets are coated on both sides, allowing printing on front and back.

Benefits:

- More creative flexibility

- Perfect for two-sided signs and photo panels

- Saves time and additional coating costs

High-Quality Aluminum Sublimation Sheets for Printing

Aluminum sublimation sheets are versatile, durable, and perfect for high-quality sublimation printing. Whether for photo panels, signage, promotional products, or personalized gifts, these sheets offer bright, long-lasting results. Choosing the right type, size, and coating ensures the best print quality and durability for any project.