Sublimation printing on metal transforms aluminum sheets into stunning, permanent prints with incredible color vibrancy. This process is perfect for photo panels, signs, and custom artwork.

HD Metal Prints – Aluminum Sublimation | Custom Photo Panels

Sublimation printing on metal is a modern way to create high-definition, long-lasting, and vibrant images. Using specially coated aluminum sheets, sublimation printing transfers images directly into the surface, making them scratch-resistant, UV-protected, and waterproof.

Common uses include:

- Wall art and photography prints

- Customized photo panels

- Metal signs and displays

- Personalized gifts

- Industrial tags and labels

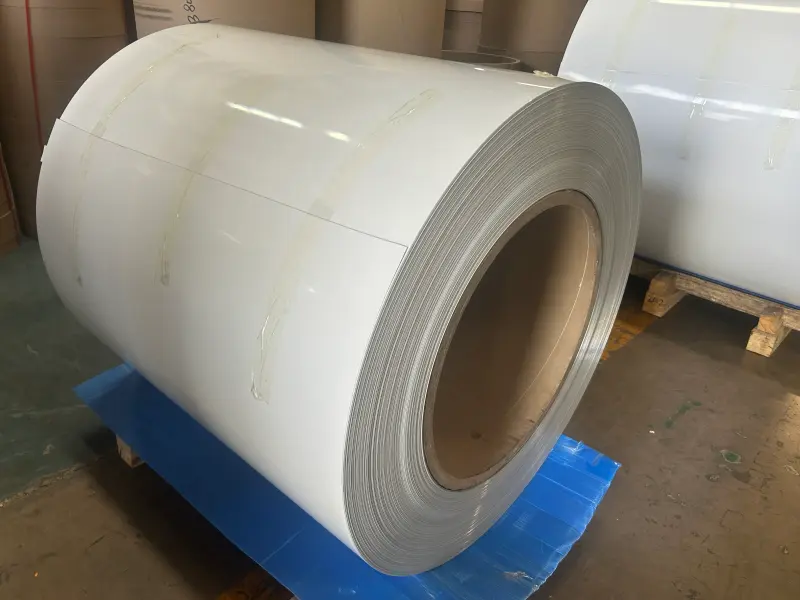

Sublimation Printing Metal Sheet

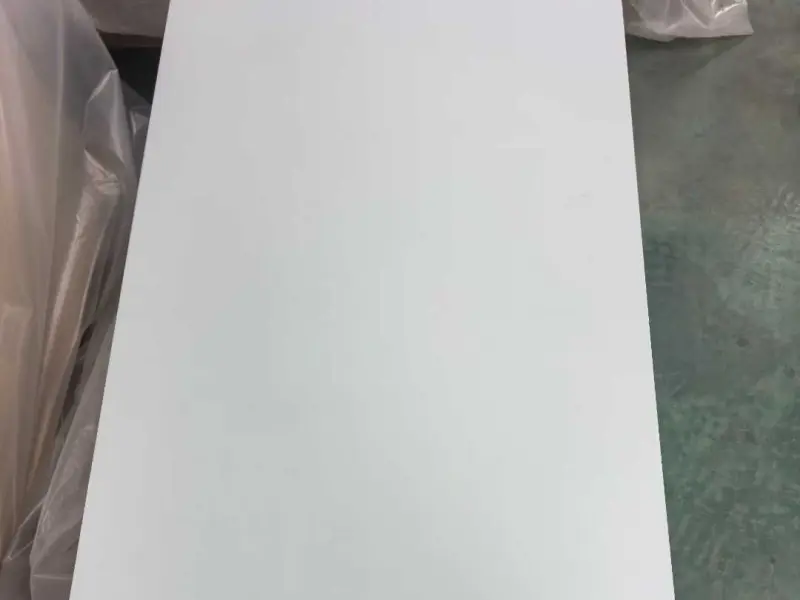

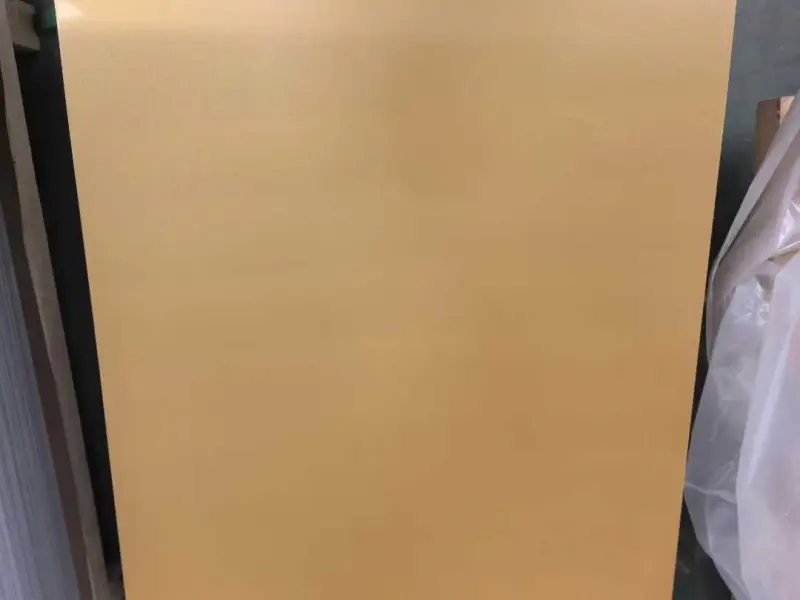

Sublimation metal sheets are made from aluminum with a polyester coating that absorbs sublimation ink. They are available in different finishes:

- Glossy white for vibrant colors

- Matte for a soft, elegant effect

- Brushed aluminum for a metallic look

Common Sizes of Sublimation Metal Sheets

| Size (inch) | Thickness (mm) | Finish Options |

|---|---|---|

| 8 x 10 | 0.5 – 1.1 | Gloss, Matte, Brushed |

| 12 x 18 | 0.8 – 1.2 | Gloss, Matte, White |

| 20 x 30 | 1.1 – 1.5 | Gloss, Matte |

| Custom sizes | 0.5 – 1.5 | Full customization |

Sublimation on Metal Signs

Aluminum Sublimation printing is widely used for metal signs because of its durability and color depth.

- Perfect for indoor and outdoor use

- Resistant to UV rays, rain, and scratches

- Ideal for business branding, street signs, and nameplates

Sublimation Metal Photo Blanks

Photo blanks are pre-coated aluminum panels ready for sublimation. They are available in different shapes such as square, rectangle, round, or custom cut.

Advantages of Using Photo Blanks

- Easy to print directly with sublimation machine

- No extra coating required

- Sharp and vivid colors after printing

- Perfect for photography studios and custom gift shops

Sublimation Printing on Aluminum

Aluminum sheets are the most popular material for sublimation printing. Benefits include:

- Lightweight but strong

- Corrosion resistant

- Can be cut and shaped into panels, signs, or decorative products

- Smooth surface ensures high-definition image quality

Table: Common Alloys for Sublimation Aluminum Sheets

| Alloy | Features | Best Use |

|---|---|---|

| 1060 | High purity, low cost | Indoor signs, small prints |

| 3003 | Anti-rust, moderate strength | Outdoor panels, photo blanks |

| 5052 | Strong corrosion resistance | Industrial & outdoor signage |

Metal Sublimation Printing Machine

- Heat press machine: Transfers ink into coated metal sheets

- Sublimation printer: Prints with sublimation ink on transfer paper

- Protective film & tape: Holds paper in place during heat transfer

Typical Machine Settings for Metal Sublimation

| Parameter | Recommended Setting |

|---|---|

| Temperature | 180°C – 200°C (356–392°F) |

| Time | 60 – 120 seconds |

| Pressure | Medium to High |

How We Make Metal Prints Explained

The process of making sublimation metal prints is simple and effective:

- Print design on sublimation transfer paper using sublimation ink

- Place paper on coated aluminum sheet with heat-resistant tape

- Press in heat press machine at recommended temperature and time

- Remove paper after cooling and check the image quality

- Final product: vivid, durable, and professional-looking print

Applications of Sublimation Printing on Metal

Sublimation on aluminum is versatile and used across different industries:

- Home decoration – HD photo panels, wall art

- Corporate branding – Office signs, company logos

- Retail & advertising – Displays, product boards

- Personal gifts – Customized photo panels, keepsakes

- Industrial use – Machine labels, ID tags

FAQ – Frequently Asked Questions

Q1: Can you sublimation print on metal?

Yes, but only on specially coated aluminum sheets designed for sublimation.

Q2: What are the settings for sublimation on metal?

Standard settings are 180°C – 200°C, 60–120 seconds, medium pressure.

Q3: How to make a sublimation metal sheet?

You need aluminum sheets pre-coated with polyester coating, available from sublimation suppliers.

Q4: What temperature do you sublimate metal?

Typically 190°C (374°F) for 90 seconds. Adjust based on sheet thickness.

Q5: Are sublimation metal prints durable?

Yes, they are scratch-resistant, waterproof, and UV-protected, making them last for years.

How We Make Metal Prints Explained

Our process for creating stunning metal prints involves several precise steps to ensure the highest quality:

- Image Preparation: Your digital image is optimized for resolution, color accuracy, and sharpness.

- Sublimation Printing: The optimized image is printed onto a special transfer paper using high-quality sublimation inks.

- Metal Blank Selection: We select the appropriate sublimation metal photo blank, usually aluminum, with a pristine polymer coating.

- Heat Press Application: The printed transfer paper is carefully aligned and placed onto the metal blank.

- Sublimation Process: The assembly is placed into a specialized heat press. Under high temperature and pressure, the ink transforms into a gas and infuses into the metal’s coating.

- Cooling and Finishing: After cooling, the paper is removed, revealing a vibrant, durable, and ready-to-display HD Metal Print.

Sublimation printing on metal Factory Supplier

Sublimation printing on metal is one of the best ways to produce high-quality, long-lasting, and vibrant photo panels, signs, and displays. With different alloys, thicknesses, and finishes, sublimation aluminum sheets are suitable for both personal and commercial projects.

By choosing a reliable factory supplier, you get:

- Consistent quality

- Wide range of sizes and finishes

- Competitive prices

- Fast delivery and customization options