What Are Metal Sublimation Blanks?

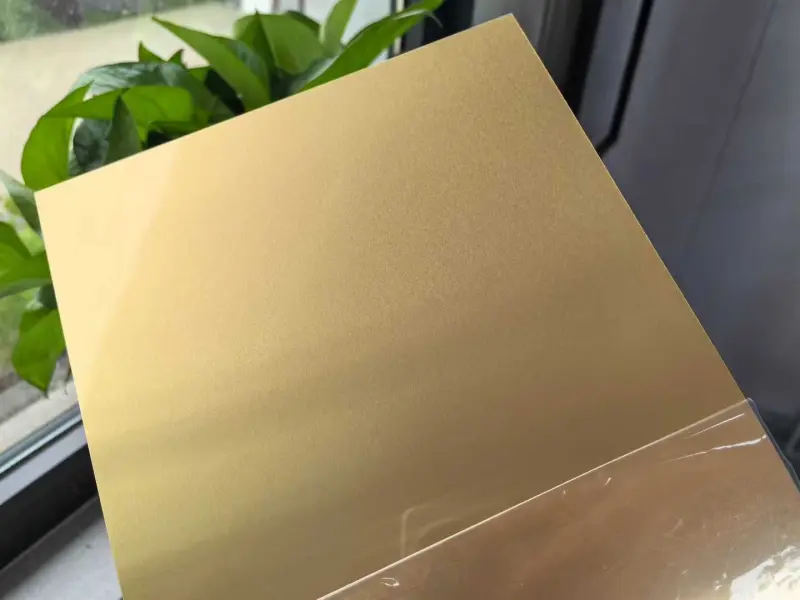

Metal sublimation blanks wholesale are aluminum sheets or cut pieces coated with a polyester layer designed to absorb sublimation inks. This coating enables sharp, durable, and colorful images to transfer onto the metal surface using heat and pressure.

Types & Specifications of Metal Sublimation Blanks

| Type | Thickness | Size Options (inches) | Finish | Notes |

|---|---|---|---|---|

| White Coated Aluminum Sheets | 0.025″ – 0.032″ | 12 x 24, 24 x 36 | High Gloss White | Large surface for big prints 1 3 |

| Photo Sign Blanks | ~0.018″ – 0.045″ | 8 x 10, 6 x 8 | White Finish | Designed for photo prints 5 |

| Round or Square Cut Sheets | 0.025″ | Custom sizes | Matte or Glossy | Ready for sublimation |

These blanks can come pre-cut or in sheets, allowing versatile use depending on project size and accuracy needs.

Benefits of Buying Wholesale Metal Sublimation Blanks

- Cost-effective: Lower unit prices when bought in bulk.

- Consistent quality: Reliable sublimation coating ensures color accuracy.

- Variety of sizes: Suitable for everything from small photo gifts to large décor.

- Durability: Metal base offers long-lasting, scratch-resistant prints.

- Ready to use: Pre-coated surface saves preparation time.

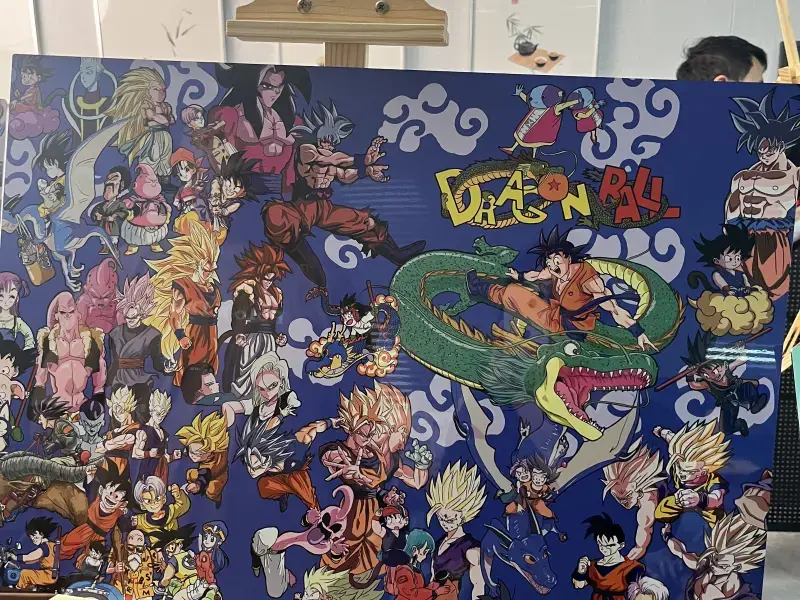

Applications of Metal Sublimation Blanks

- Wall art and décor

- Custom photo panels

- Personalized gifts and awards

- Signage for business and events

- Home décor items like trays and coasters

Why Choose Metal for Sublimation?

| Feature | Metal Sublimation | Other Materials |

|---|---|---|

| Durability | Scratch and rust-resistant | Less durable (wood/plastic) |

| Print Quality | Vibrant and sharp colors | May fade over time |

| Usability | Easy heat transfer process | Some materials need prep |

| Outdoor Use | UV-resistant coatings option | Often unsuitable |

Tips for Effective Use

- Store blanks flat and dry to maintain coating quality.

- Use proper heat press temperature and time settings for best results.

- Handle edges carefully to avoid damage or peeling of coating.

Order Process

1: Request Quote

- Provide product requirements

- Specify quantities

- Discuss customization

2: Sample Approval

- Receive production samples

- Approve quality

- Confirm specifications

3: Production

- 7-10 day turnaround

- Quality control checks

- Packaging completion

4: Shipping

- FOB or CIF options

- Tracking provided

- Insurance available

Why Choose Wholesale?

Cost Savings:

- Factory direct pricing

- Volume discounts

- Reduced per-unit cost

- Better profit margins

Quality Control:

- Consistent manufacturing

- Batch testing

- Quality guarantees

- Reliable supply

Business Growth:

- Expand product lines

- Meet larger orders

- Competitive pricing

- Brand development

MOQ Requirements

| Product Category | Minimum Order | Mixed Orders |

|---|---|---|

| Standard panels | 50 units | Yes |

| Custom shapes | 100 units | No |

| Private label | 500 units | Yes |

| Special coating | 200 units | Yes |

FAQ

Q: What’s the minimum order value?

A: $500 minimum for wholesale orders

Q: Do you offer custom sizes?

A: Yes, with 1000 unit minimum

Q: Are samples available?

A: Yes, sample kits for $25 (credited to first order)

Q: What payment terms?

A: Net 30 for established accounts, otherwise 50% deposit

Q: Do you drop ship?

A: Yes, drop shipping services available

Leave a Reply

You must be logged in to post a comment.