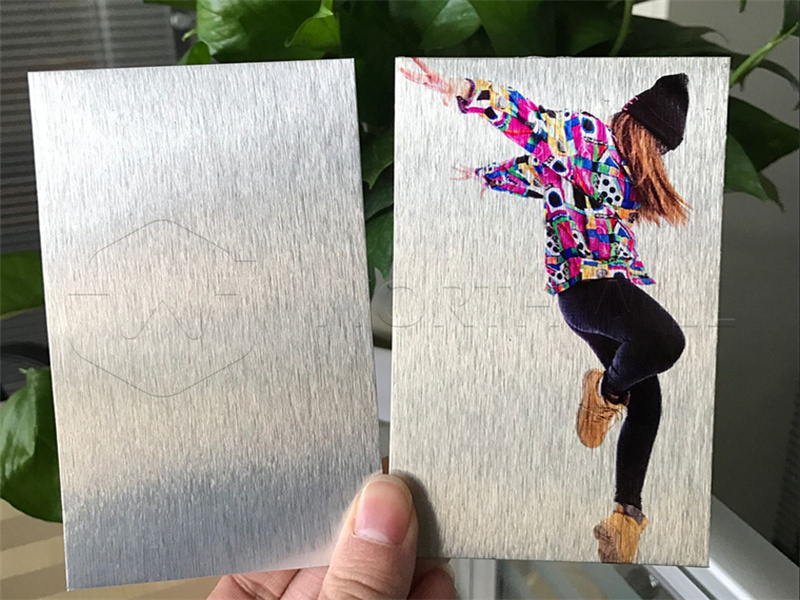

Sublimation sign blanks are pre-treated panels, typically made of aluminum, specifically engineered for the sublimation printing process. Each blank features a durable polyester coating that is essential for absorbing the sublimated ink. When heat and pressure are applied using a heat press, the special sublimation ink transforms into a gas and infuses directly into this coating.

Unlike vinyl or surface prints that can peel or fade, the image becomes a permanent part of the sign blank’s surface, making sublimation sign blanks exceptionally durable and resistant to various environmental conditions.

What Are Sublimation Sign Blanks?

Sublimation sign blanks are pre-coated aluminum panels designed for vibrant, permanent full-color printing. These specialized blanks enable:

Photographic image quality

Scratch-resistant surfaces

Idoor/outdoor durability

Professional-grade signage

Classification by Sign Type

| Blank Type | Common Sizes | Best Applications |

|---|---|---|

| Wall Signs | 8×10″ to 24×36″ | Office decor, retail |

| Outdoor Signs | 12×18″ to 36×48″ | Yard signs, business |

| Desk Plates | 3×8″ to 5×7″ | Nameplates, awards |

| Hanging Signs | 6×6″ to 12×12″ | Store displays |

| Custom Shapes | Various | Specialty promotions |

Thickness Options

| Thickness | Weight | Rigidity | Best For |

|---|---|---|---|

| 1.0mm | Light | Flexible | Indoor wall signs |

| 1.5mm | Standard | Semi-rigid | Most applications |

| 2.0mm | Heavy | Rigid | Outdoor/freestanding |

| 3.0mm | Extra Heavy | Very rigid | Large format signs |

Most popular: 1.5mm for balanced performance

Aluminum Alloy Specifications

| Alloy | Characteristics | Signage Performance |

|---|---|---|

| 1050 | Economical | Basic indoor use |

| 3003 | Standard | Most common choice |

| 5052 | Weather-resistant | Premium outdoor signs |

| 6061 | Structural | Heavy-duty mounting |

Packaging Methods

- Small Signs (<18″):

✓ Individual poly bags

✓ Cardboard backers

✓ 25-50 units per case - Large Signs (18″+):

✓ Foam-separated layers

✓ Edge protectors

✓ Double-wall boxes - Bulk Orders:

✓ Wooden crates

✓ Moisture barrier

✓ Palletized shipping

Technical Specifications

| Parameter | Specification |

|---|---|

| Sublimation Temp | 190°C ±5° |

| Press Time | 60-90 seconds |

| Coating Thickness | 20-30 microns |

| Color Accuracy | 98% sRGB |

| Outdoor Rating | 3-5 years (with laminate) |

Applications

Business Signage

- Storefront displays

- Menu boards

- Trade show graphics

- Real estate signs

Office Decor

- Motivational quotes

- Branded wall art

- Department identifiers

- Safety signage

Personalized Items

- Family name signs

- Wedding welcome signs

- Graduation announcements

- Pet memorials

Promotional Uses

- Event sponsorships

- Grand opening displays

- Seasonal promotions

- Political campaigns

Sublimation Printing Process

- Design Setup (300 DPI minimum resolution)

- Blank Preparation (clean with alcohol wipe)

- Heat Press Setup (190°C, medium pressure)

- Transfer Process (60-90 second dwell time)

- Cooling & Finishing (add hanging hardware)

Quality Comparison

| Feature | Aluminum | Acrylic | MDF |

|---|---|---|---|

| Image Quality | Excellent | Good | Fair |

| Durability | High | Medium | Low |

| Weather Resistance | Good (with coating) | Poor | None |

| Weight | Light | Medium | Heavy |

Price Factors (2024 Market)

| Factor | Price Impact |

|---|---|

| Size | 24×36″ = 4x 12×18″ cost |

| Thickness | 2.0mm = +25% vs 1.5mm |

| Quantity | 50+ pieces: 15% discount |

| Coating | Matte = +10% vs gloss |

| Custom Shapes | +20-50% |

*Current price range: $5-$50 per blank*

Top Suppliers

US Manufacturers

- SignBlank Co.: Best for standard sizes

- AlumiPrint: Premium outdoor blanks

- SubliSource: Custom shape specialists

Global Options

- China Sublimation: Low MOQ (25 pieces)

- EuroSign Blanks: High-end coatings

- Canada Metal Arts: Fast NA shipping

Buying Checklist

✅ Verify coating compatibility

✅ Request color profile

✅ Check return policies

✅ Compare bulk discounts

✅ Review packaging protection

FAQ

Q: How long do sublimated signs last outdoors?

A: 3-5 years with UV laminate protection

Q: Can blanks be cut after printing?

A: Yes – use metal shears or CNC router

Q: Minimum order quantities?

A: Typically 10-25 pieces for custom work

Q: Shelf life of unprinted blanks?

A: 2+ years stored flat in dry conditions

Q: Can I use a regular printer for sublimation sign blanks?

A: No. You need a dedicated sublimation printer loaded with sublimation inks and special transfer paper to properly print onto sublimation sign blanks. Standard inkjet or laser printers will not work.

Q: How do I cut sublimation sign blanks to size?

A: Thinner sublimation sign blanks (up to about 0.040″ or 1mm) can often be cut with a specialized shear or guillotine. For thicker blanks or intricate shapes, professional equipment like a CNC router or laser cutter (specifically a fiber laser for aluminum cutting, or CO2 for coating only) is typically required.

Q: Are all sublimation sign blanks suitable for outdoor use?

A: While many sublimation sign blanks are designed for outdoor use with UV-resistant coatings, it’s crucial to check the specific product description from your supplier. Not all blanks have the same level of UV protection.

Q: How long do sublimation signs last outdoors?

A: High-quality sublimation signs designed for outdoor use can last many years, often 5-10+ years, without significant fading, especially when exposed to standard weather conditions. Lifespan can vary based on direct sun exposure and environmental severity.

Q: Can I sublimate on both sides of a sign blank?

A: Yes, some sublimation sign blanks are specifically coated on both sides for double-sided printing, making them ideal for hanging signs or displays where visibility from multiple angles is desired.

How to Select the Right Sublimation Sign Blanks

Choosing the perfect sublimation sign blanks requires careful consideration to ensure the best outcome for your project:

- Intended Environment: Will the sign be indoors or outdoors? For outdoor use, prioritize UV and weather-resistant coatings and appropriate thickness.

- Visual Impact: What kind of finish will best complement your design and the viewing conditions? Glossy for vibrancy, matte for reduced glare, brushed for a unique texture.

- Size and Thickness: Determine the necessary dimensions and thickness for the sign’s stability, visibility, and handling. A large outdoor sign needs more rigidity than a small indoor plaque.

- Mounting Method: Consider how the sign will be mounted (drilled, adhered, framed). This might influence the blank’s thickness or if pre-drilled holes are needed.

- Budget: While quality is important, compare options within your budget, keeping in mind that thicker, specialized sublimation sign blanks might cost more.

- Supplier Reputation: Purchase from reputable suppliers specializing in sublimation sign blanks to ensure consistent quality, proper coating, and reliable product support.

By carefully evaluating these factors, you can make an informed decision and select the ideal sublimation sign blanks for your needs.

Sublimation sign blanks offer professional-quality results for businesses and creatives. For best results:

- Choose thickness based on mounting needs

- Select size for visibility requirements

- Verify coating specifications

- Order samples before large purchases

Always follow manufacturer guidelines for time/temperature settings during pressing.