Are you looking for a way to create stunning, long-lasting prints with incredible detail? Sublimation blanks aluminum offer an exceptional solution for businesses and crafters alike. These specially prepared metal sheets allow you to transfer vibrant, high-definition images directly onto their surface, resulting in durable and eye-catching products. This guide will explore everything you need to know about sublimation aluminum blanks, from their specifications to their many uses.

Key Specifications of Sublimation Blanks Aluminum

Understanding the specifications of sublimation blanks aluminum helps you choose the right product for your needs. Here’s a detailed look:

Classification

Sublimation aluminum blanks come in various forms, designed for different purposes:

- Flat Sheets/Panels: These are large, flat pieces used for wall art, signage, and custom decorative panels.

- Pre-Cut Shapes: Many blanks are available in specific shapes like circles, squares, rectangles, or even custom designs for items such as keychains, coasters, or awards.

- Specialty Items: This includes pre-fabricated items like photo frames, business card holders, luggage tags, and more, all ready for sublimation.

Each classification serves a distinct need, ensuring there’s an aluminum sublimation blank for almost any project.

Thickness

The thickness of sublimation blanks aluminum is an important factor, affecting rigidity, weight, and perceived quality. Common thicknesses are measured in millimeters (mm) or inches.

| Thickness (mm) | Thickness (inches) | Typical Use |

|---|---|---|

| 0.45 mm | 0.018″ | Light signage, decorative elements |

| 0.5 mm | 0.020″ | Photo panels, smaller signs, keychains |

| 0.75 mm | 0.030″ | Medium-duty signs, awards, durable photo panels |

| 1.0 mm | 0.040″ | Premium photo panels, sturdy signs, art pieces |

| 1.1 mm | 0.043″ | High-end signs, architectural panels |

| 1.5 mm+ | 0.060″+ | Very heavy-duty signs, industrial applications |

Choosing the correct thickness ensures your final product has the desired feel and structural integrity. Thicker aluminum sublimation blanks generally offer greater rigidity and a more premium feel.

Surface Finish (Subtitle)

The “副标” or subtitle for sublimation blanks aluminum often refers to the surface finish of the polyester coating. This finish significantly impacts the visual effect of your sublimated image.

- Glossy: The most popular choice, offering a high-sheen, reflective surface that makes colors pop and enhances vibrancy. Ideal for photographic prints.

- Matte: Provides a non-reflective, elegant finish that reduces glare and offers a more subdued, sophisticated look. Great for art reproductions or text-heavy designs.

- Brushed: Features a subtle brushed texture under the coating, adding a unique, metallic look. The texture is visible through the print, adding an artistic touch.

- White: A common base color for the coating, providing a neutral background for true color representation.

- Silver: The natural silver color of the aluminum shows through lighter areas of your design, creating a metallic effect.

Your choice of finish depends on the desired aesthetic for your sublimation aluminum product.

Alloy

The aluminum alloy used for sublimation blanks affects the material’s strength, corrosion resistance, and overall quality. While specific alloy numbers (e.g., 1100, 3003, 5052, 6061) might vary by manufacturer, they are chosen for their suitability for coating and their inherent properties.

- 1000 Series (e.g., 1100): Known for excellent corrosion resistance and formability, often used where pure aluminum properties are desired.

- 3000 Series (e.g., 3003): A common, all-purpose alloy with good formability and moderate strength, often used in general applications.

- 5000 Series (e.g., 5052): Offers good strength, excellent corrosion resistance, especially in marine environments, and good weldability.

- 6000 Series (e.g., 6061): A heat-treatable alloy with good mechanical properties and general corrosion resistance, used for structural components.

The choice of alloy ensures the sublimation blanks aluminum are stable and durable enough for the sublimation process and their intended use.

Packaging

Proper packaging is crucial for sublimation blanks aluminum to prevent damage during transit and storage. Manufacturers typically use several layers of protection:

- Protective Film:

- Individual Sleeves/Bags:

- Cardboard Boxes:

- Edge Protectors:

- Pallets/Crates:

Good packaging ensures your sublimation aluminum blanks arrive in perfect condition, ready for printing.

Applications of Sublimation Blanks Aluminum

The versatility of sublimation blanks aluminum makes them suitable for a vast array of applications across various industries. Here are some popular uses:

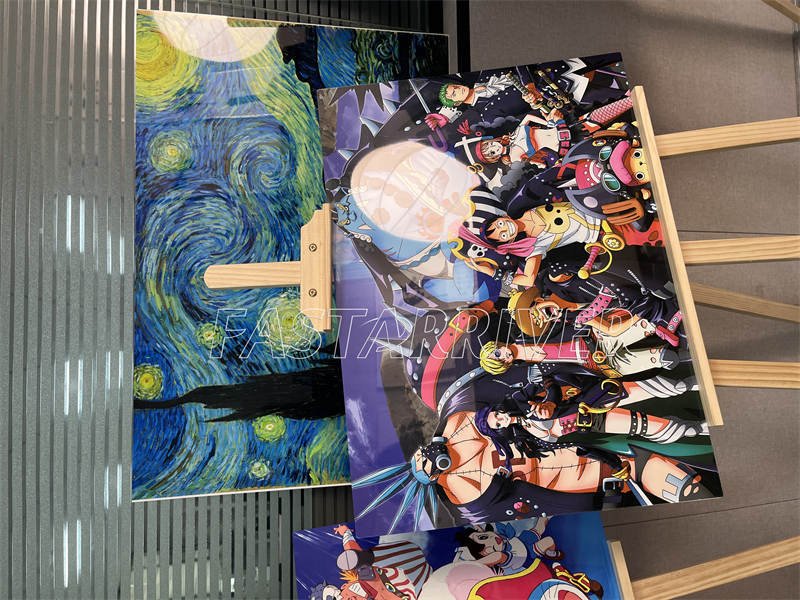

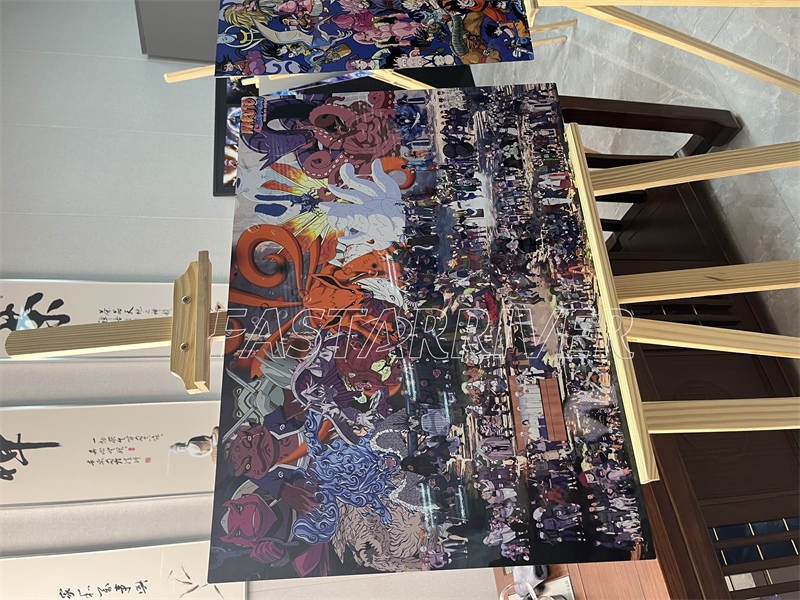

- Personalized Photo Panels: Turn cherished memories into stunning, vibrant wall art.

- Indoor and Outdoor Signage: Create durable and weather-resistant signs for businesses, events, or directional purposes.

- Awards and Trophies: Design elegant and long-lasting awards with crisp details and brilliant colors.

- Decorative Art Pieces: Produce unique and modern art for home or office decor.

- Name Tags and Badges: Durable and professional tags for employees or events.

- Custom Keychains and Luggage Tags: Personalized accessories that stand the test of time.

- Marketing Materials: Create unique business cards, promotional items, or display pieces.

- Informational Plaques: Durable and legible plaques for historical sites, museums, or industrial settings.

- Restaurant Menus or Table Tents: Easy-to-clean and stylish options for dining establishments.

- Jewelry Components: Craft lightweight and custom earrings, pendants, or bracelets.

These are just a few examples; the creative possibilities with sublimation aluminum are truly endless.

How to Select the Right Sublimation Aluminum Blanks

Choosing the correct sublimation blanks aluminum involves considering several factors to ensure your project’s success:

- Project Purpose: What will the finished product be used for? This will guide your choice of size, shape, and thickness. For outdoor signs, prioritize weather-resistant coatings and thicker blanks. For delicate photo art, focus on glossy finishes.

- Desired Aesthetic: Do you want a vibrant, reflective look (glossy) or a muted, sophisticated feel (matte)? Consider how the finish will impact your design.

- Thickness Requirements: Match the thickness to the rigidity and durability needed. A small keychain won’t need the same thickness as a large outdoor sign.

- Quality of Coating: The polyester coating is critical. Look for blanks with a smooth, even, and defect-free coating for the best print results.

- Supplier Reputation: Purchase from reputable suppliers who specialize in sublimation blanks aluminum to ensure consistent quality and proper storage.

By carefully evaluating these points, you can select the perfect aluminum sublimation blanks for your specific needs.

Caring for Your Sublimated Aluminum Products

While sublimation blanks aluminum produce very durable prints, a little care can help them last even longer:

- Cleaning: For most sublimated aluminum items, simply wipe them clean with a soft, damp cloth. Avoid harsh chemicals or abrasive scrubbing pads, especially on glossy finishes, as they could scratch the surface.

- Avoid Extreme Temperatures: The prints are durable.

- Storage: If storing unused sublimation aluminum blanks, keep them in their original protective packaging in a cool, dry place to prevent dust and scratches.

Proper care ensures your beautiful sublimation aluminum creations maintain their vibrant look for years to come.

Frequently Asked Questions (FAQs) about Sublimation Blanks Aluminum

Here are some common questions regarding sublimation blanks aluminum:

Q: Can I use any aluminum for sublimation?

A: No. Standard aluminum will not work for sublimation. It requires a special polyester coating specifically designed to accept the sublimated ink. Without this coating, the ink cannot bond to the metal.

Q: What resolution should my images be for sublimation on aluminum?

A: For best results, use high-resolution images, typically 300 DPI (dots per inch) or higher. This ensures crisp details and prevents pixelation on your sublimation aluminum prints.

Q: Are sublimated aluminum products outdoor-safe?

A: Many sublimation blanks aluminum are designed with UV and weather-resistant coatings, making them suitable for outdoor use. However, always check the product specifications from your supplier.

Q: How long do sublimated prints on aluminum last?

A: When properly cared for, sublimated prints on aluminum can last for many years, even decades, without significant fading or degradation, thanks to the durable coating and infused ink.

Q: Can I cut sublimation aluminum blanks?

A: Yes, thinner aluminum sublimation blanks (up to 0.040″) can often be cut with specialized shears or guillotines. For thicker blanks or intricate shapes, a CNC router or laser cutter (CO2 laser for cutting the coating, fiber laser for engraving the metal) is typically used.

Why Choose Sublimation Aluminium Blanks?

The popularity of sublimation aluminum blanks stems from their unique advantages:

Easy to Clean: The smooth, durable surface can be easily wiped clean.

Exceptional Durability: The infused image is highly resistant to scratches, abrasion, and chemicals. This makes them ideal for both indoor and outdoor use.

Vibrant, High-Definition Prints: Sublimation allows for photographic quality images with rich colors and sharp details, bringing your designs to life.

Lightweight and Strong: Aluminum is naturally lightweight yet robust, making it easy to handle and suitable for various applications without adding significant bulk.

Weather and UV Resistance: Designed to withstand exposure to sunlight and moisture, ensuring your prints remain vivid over time.

Versatility: Available in a wide range of shapes, sizes, and finishes, these blanks.