Aluminum sublimation metal sheet is specially coated metal sheets designed for high-quality digital printing using heat transfer technology. . Unlike traditional prints that sit on top of a substrate, sublimation turns ink into a gas, which then bonds with the unique polymer coating on the aluminum, resulting in a print that is scratch-resistant, waterproof, and surprisingly resilient.

Classification of Aluminum Sublimation Metal Sheet

Aluminum sublimation metal sheet is primarily classified by its surface finish, which dictates the final look and feel of your printed image, and its form.

| Classification Type | Details |

|---|---|

| By Surface Finish | This is the most critical classification, affecting print vibrancy and aesthetic. |

| Gloss White | The most popular choice, offering maximum color vibrancy and contrast. Ideal for photographic prints, portraits, and designs requiring vivid, luminous colors. |

| Matte White | Provides a non-glare, softer finish. Still offers excellent color saturation but reduces reflections, making it suitable for art prints or displays in brightly lit areas. |

| Clear (Silver) | Allows the natural brushed or unbrushed aluminum base to show through in areas of the design that are white or light-colored. Creates a unique metallic, iridescent effect. |

| Brushed | Features a distinctive brushed texture (e.g., brushed silver, brushed gold) where the brushing lines are visible, especially through clear coatings. Adds depth and a modern industrial feel. |

| Gold | Coated with a gold-toned finish, giving prints a luxurious, rich metallic gold background. Perfect for awards, certificates, or elegant decorative pieces. |

| By Form | Sublimation aluminum is available in various forms to suit different production needs. |

| Flat Sheets | Large, raw sublimation blank sheets that can be cut down to any custom size or shape by the user. Offers maximum flexibility for bulk production. |

| Pre-Cut Blanks | Sheets already cut into popular sizes and shapes, such as rectangles, circles, ovals, or custom shapes for specific products (e.g., photo panels, keychains, ornaments, signs, nameplates). |

Thickness: Finding the Right Balance

The thickness of aluminum sublimation metal sheet is a crucial specification that affects the rigidity, feel, and intended application of the final product. Thicker sheets offer greater durability and a more substantial feel, while thinner sheets are lighter and more flexible.

| Thickness Range (mm) | Typical Imperial (Inches) | Characteristics & Common Uses |

|---|---|---|

| 0.5mm – 0.7mm | 0.020″ – 0.028″ | Common for smaller, lightweight items like keychains, luggage tags, small ornaments, name tags, or very thin wall art panels. Easy to cut and cost-effective for high-volume small items. |

| 1.0mm – 1.2mm | 0.039″ – 0.047″ | The most popular and versatile thickness for high-quality metal prints, photo panels, signs, awards, and medium-sized wall art. Offers a good balance of rigidity, durability, and manageable weight. |

| 1.5mm – 3.0mm+ | 0.059″ – 0.118″+ | Used for larger, more robust display panels, outdoor signage, or applications where maximum rigidity and impact resistance are required. Less common for standard photo prints due to weight and cost. |

Selecting the correct sublimation aluminum blank thickness ensures the finished product meets both aesthetic and functional demands.

Alloy: The Stable Foundation

While the magic of sublimation happens on the polymer coating, the underlying aluminum alloy provides the stable, flat, and durable base for the sublimation metal sheet. The choice of alloy is important for ensuring the sheet remains perfectly flat during the heating process and offers long-term integrity.

| Alloy Series | Common Alloys | Characteristics Relevant to Sublimation Applications |

|---|---|---|

| 1000 Series (Pure Al) | 1050, 1100 | High purity, known for excellent flatness, good formability, and superior corrosion resistance. These properties make it an ideal, stable base for consistent coating and high-quality prints. |

| 3000 Series (Al-Mn) | 3003 | Offers moderate strength, good workability, and excellent corrosion resistance. Also provides a very stable and flat substrate, suitable for reliable sublimation blanks. |

Manufacturers select these alloys because of their inherent flatness, minimal warping during heat application, and excellent surface quality, which ensures the polymer coating adheres consistently and performs optimally.

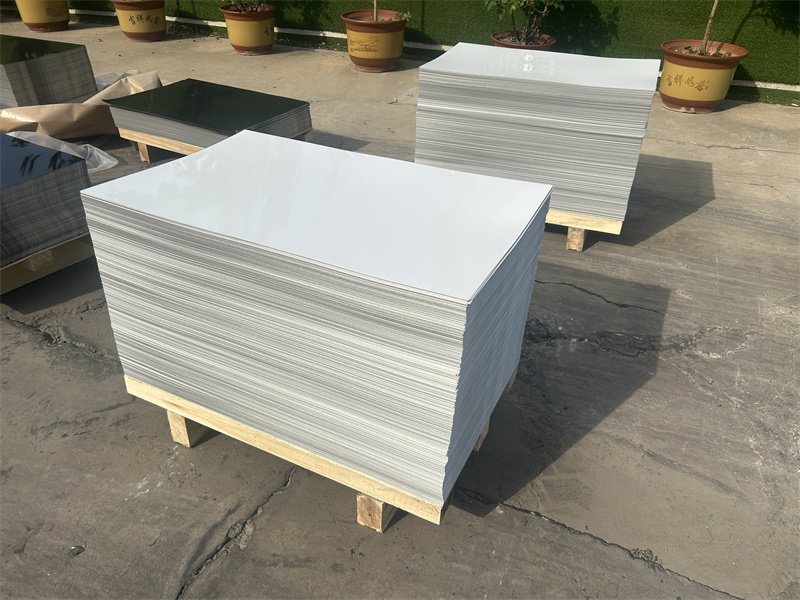

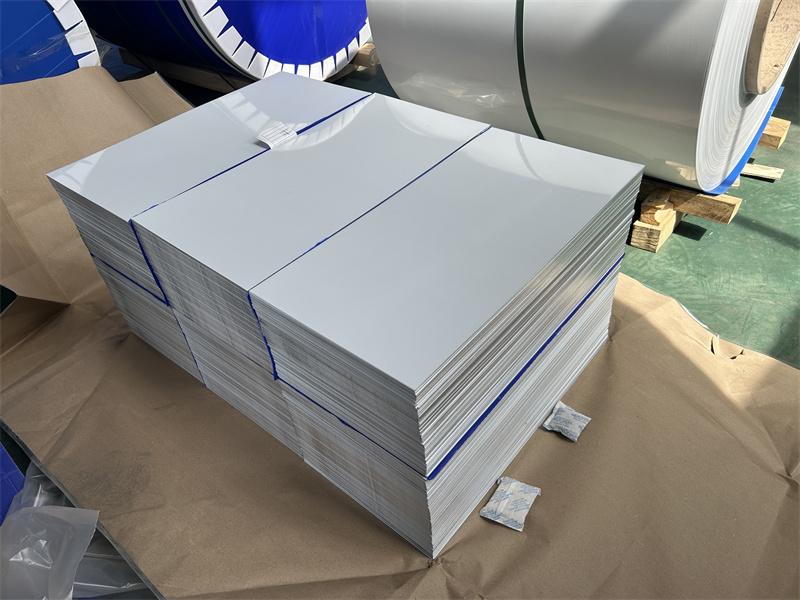

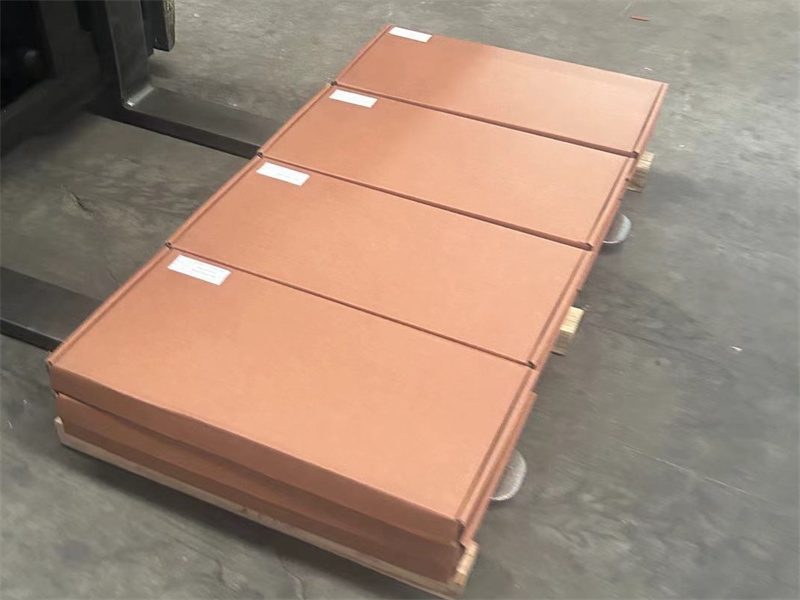

Packaging: Ensuring Pristine Blanks

Given the delicate nature of the specialized polymer coating on aluminum sublimation metal sheet, proper packaging is critical. It ensures that the sublimation blanks arrive in pristine, scratch-free condition, ready for printing.

| Packaging Component | Purpose |

|---|---|

| Individual Protective Film | A thin, transparent plastic film applied to the top (sublimation-ready) side of each sheet. This is peeled off just before printing to reveal a perfect, clean surface. |

| Flat Stacking with Interleaving | Sheets are carefully stacked flat with protective interleaving paper or thin foam sheets between them to prevent scratching and ensure stability within the package. |

| Sturdy Cardboard Cartons | Bundles of sheets are placed in strong, custom-sized cardboard cartons that prevent bending, corner damage, and provide impact protection during transit. |

| Wooden Pallets/Skids | For larger quantities or international shipping, cartons are stacked securely on fumigated wooden pallets or skids, facilitating safe handling with forklifts and stable stacking. |

| Wooden Crates/Boxes | For maximum protection, especially for very large, thick, or high-value orders, robust wooden crates or boxes are used to enclose the entire shipment, offering superior protection. |

| Moisture-Proof Wrap/Desiccants | Plastic film wrap around cartons and/or desiccant packs inside the packaging to protect the sheets and their coatings from humidity and moisture during transport and storage. |

Reliable suppliers understand the importance of meticulous sublimation metal sheet packaging to protect your investment.

Why Choose Sublimation Aluminum Sheets?

| Feature | Benefit |

|---|---|

| Heat Transfer Coating | Excellent ink absorption for vivid image transfer |

| Lightweight | Easy to handle, install, and ship |

| Corrosion Resistant | Long lifespan for indoor and outdoor use |

| Customizable Sizes | Suitable for various design and product needs |

| Multiple Finishes | Glossy, matte, brushed effects for different applications |