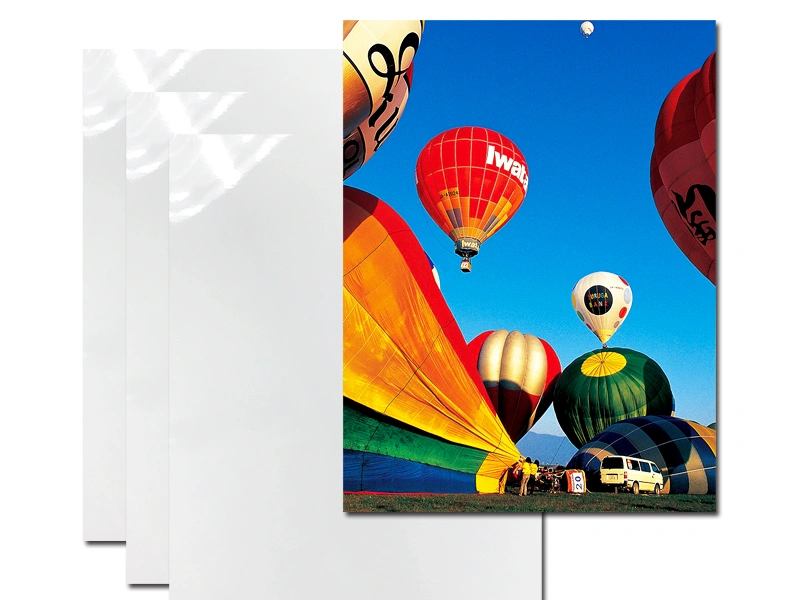

Aluminum sublimation panels are specially coated aluminum sheets designed for dye-sublimation printing. These panels allow for full-color, high-resolution images that are vibrant, long-lasting, and scratch-resistant. Popular in photography, signage, decoration, and promotional products, sublimation aluminum panels provide a sleek and professional finish.

Choosing the right aluminum sublimation panel supplier ensures consistent quality, fast delivery, and proper coating for your heat-press needs.

Product Specification

| Item | Detail |

|---|---|

| Classification | Coated aluminum sheet for sublimation printing |

| Thickness | 0.45 mm – 2.0 mm standard; custom thickness available |

| Sub-label (Surface Finish) | Glossy white, matte white, brushed silver, brushed gold, clear |

| Alloy | 1050 / 1060 (soft & flat) or 3003 / 5052 (stronger & stiffer) |

Keywords included naturally: aluminum sublimation panels, coated aluminum sheet, dye-sublimation printing panel.

Key Features of Aluminum Sublimation Panels

- Bright Color Output – Coated surface enhances ink vibrancy and detail.

- Scratch-Resistant Finish – Tough polyester coating protects printed image.

- High Heat Resistance – Holds shape at up to 200°C, ideal for heat-press machines.

- Lightweight and Flat – Easy to handle, ship, and frame.

- Durable and Waterproof – Ideal for long-term indoor and short-term outdoor use.

- Environmentally Friendly – 100% recyclable aluminum base.

Applications of Sublimation Aluminum Panels

Aluminum sublimation panels are widely used in commercial, personal, and industrial sectors. Here are some common uses:

Photo and Wall Art

- • Metal photo prints

- • Canvas-style image panels

- • Custom gallery walls

Interior Decoration

- • Wall cladding

- • Signboards and display panels

- • Elevator and lobby artwork

Signage

- • Directional signs

- • Office and store signs

- • Menu boards

Awards and Recognition

- • Plaques and certificates

- • Event trophies

- • Corporate gifts

Promotional Items

- • Keychains and magnets

- • Metal business cards

- • Luggage tags

Industrial Uses

- • Equipment labeling

- • Nameplates

- • Control panels

Available Surface Finishes

5.1 Gloss White

High reflectivity and vivid color—ideal for photography and high-detail designs.

5.2 Matte White

Anti-glare finish—great for text-heavy signs or indoor displays.

5.3 Brushed Silver / Brushed Gold

Metal texture shines through light areas—adds a premium, elegant effect.

5.4 Clear Coated

Transparent topcoat—shows natural aluminum beneath for creative backgrounds.

Choosing the Right Thickness

| Thickness | Recommended Use |

|---|---|

| 0.45 mm – 0.6 mm | Lightweight gifts, magnets, nameplates |

| 0.7 mm – 1.0 mm | Photo panels, plaques, signs |

| 1.2 mm – 2.0 mm | Decorative walls, commercial signage, furniture inlays |

Tip: Thicker panels reduce warping during pressing and are more impact-resistant.

Production and Quality Control

- Raw Aluminum Selection – High-purity 1050/1060 or stronger 3003/5052 alloys.

- Degreasing & Cleaning – Ensures surface is dust- and oil-free.

- Polyester Coating – Uniform layer applied and baked at high temperature.

- Protective Film Application – PE film on one or both sides to prevent scratches.

- Cutting & Packaging – Sheets cut to standard or custom sizes, then stacked with corner protection.

- Inspection – Color uniformity, coating adhesion, and flatness are tested for every batch.

Frequently Asked Questions

Q1: Can aluminum sublimation panels be used outdoors?

Yes—for short-term use. For long-term outdoor display, UV-resistant coating is recommended.

Q2: What heat-press settings are ideal?

190°C to 200°C for 60 seconds at medium pressure works best.

Q3: Can the panels be cut or drilled after printing?

Yes, use a laser cutter, CNC, or shear. Cut before printing if possible for cleaner edges.

Q4: Do you offer double-sided coated panels?

Yes, double-sided sublimation sheets are available upon request.

How to Order Aluminum Sublimation Panels

- Step 1: Choose surface finish, thickness, and size.

- Step 2: Request a sample if needed (standard A4 sheets are often free).

- Step 3: Receive quotation with lead time and shipping options.

- Step 4: Confirm order and receive tracking upon shipment.

We support small batches and bulk orders with stable supply and global shipping.

Conclusion

Aluminum sublimation panels are the perfect solution for creating high-quality, durable printed products. Their versatility, lightweight design, and brilliant color response make them ideal for many applications—from personal gifts to commercial signs.

Whether you need coated aluminum sheets for printing art, signage, or awards, a trusted supplier ensures consistent quality and service. Contact us now to explore sizes, colors, and pricing options tailored to your business.