Dye sublimation on aluminum provides unmatched color brilliance, long life, and a professional finish.

Whether for photo panels, signage, or decorative metal prints, this technique ensures your designs remain vivid, durable, and elegant.

What Is Dye Sublimation on Aluminum?

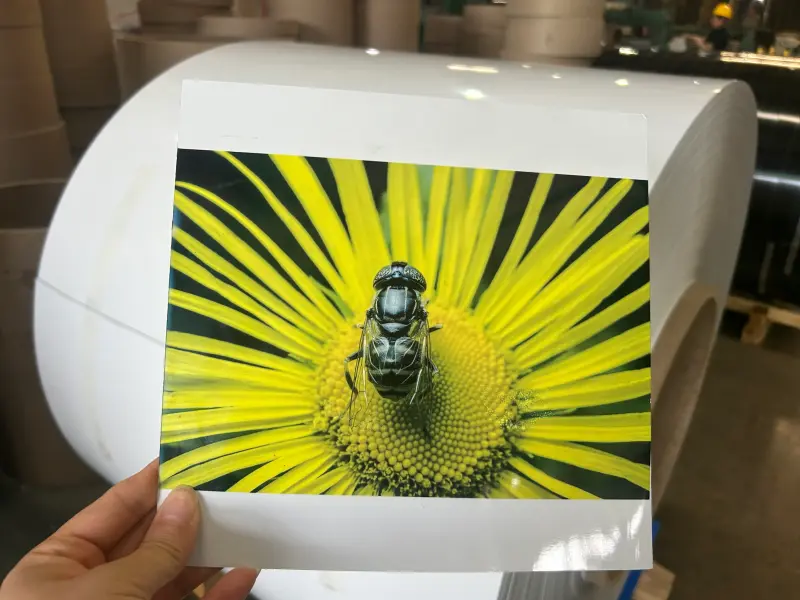

Dye sublimation on aluminum is a digital printing process that transfers dye into a coated metal surface using heat and pressure.

The result is a vivid, permanent, and scratch-resistant image directly infused into the aluminum coating — not printed on top.

This method is popular for photo printing, signage, and display panels because of its durability and color depth.

Key Features:

- High-resolution photo quality

- Fade-resistant and waterproof

- Lightweight and rust-free aluminum

- Long-lasting glossy or matte surface

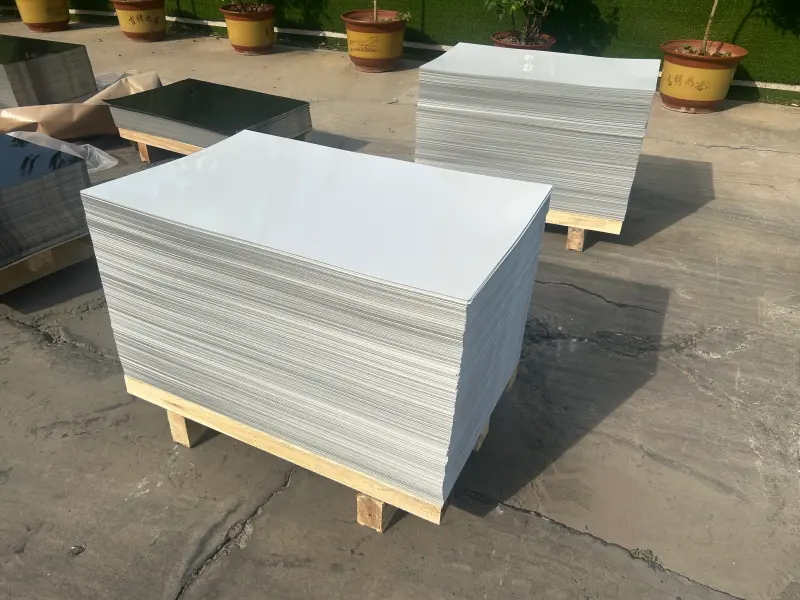

Specifications of Aluminum Sheets for Dye Sublimation

Below is a general table of aluminum sheet specifications suitable for sublimation printing:

| Parameter | Specification |

|---|---|

| Material | Aluminum alloy 1050 / 1060 / 5052 |

| Thickness | 0.45mm – 1.2mm |

| Size | A4, A3, 12×18”, 24×36”, or customized |

| Surface finish | Glossy / Matte / Brushed / White coated |

| Coating type | Polymer sublimation coating |

| Temperature | 180–200°C |

| Time | 50–70 seconds |

| Pressure | Medium to high |

These sheets are pre-treated with a special sublimation coating, allowing the dye to bond directly with the surface under heat.

Types of Aluminum Sheets for Dye Sublimation

| Type | Description | Finish |

|---|---|---|

| White Glossy Sheet | High brightness for vivid color photos | Glossy |

| Matte Silver Sheet | Non-reflective surface, elegant look | Matte |

| Brushed Aluminum Sheet | Metallic texture for artistic or industrial style | Brushed |

| Clear Gloss Sheet | Transparent base for custom design | Glossy |

| Gold or Copper Finish Sheet | Premium look for awards or signs | Glossy |

Each surface type produces a unique visual effect — glossy types show vivid colors, while brushed and matte types give a soft, professional tone.

Dye Sublimation Printing Process

The dye-sublimation printing process involves four main steps:

- Image Design: Print the image using sublimation ink on transfer paper.

- Positioning: Place the printed paper face down on the aluminum sheet.

- Heat Transfer: Apply heat (around 190°C) and pressure using a heat press.

- Cooling: Remove the paper and let the sheet cool to reveal the final image.

Typical Heat Transfer Conditions:

| Parameter | Value |

|---|---|

| Temperature | 185–195°C |

| Time | 60–70 seconds |

| Pressure | 0.4–0.6 MPa |

Pro Tip: Always preheat the press and use protective paper to avoid ghosting or ink bleed.

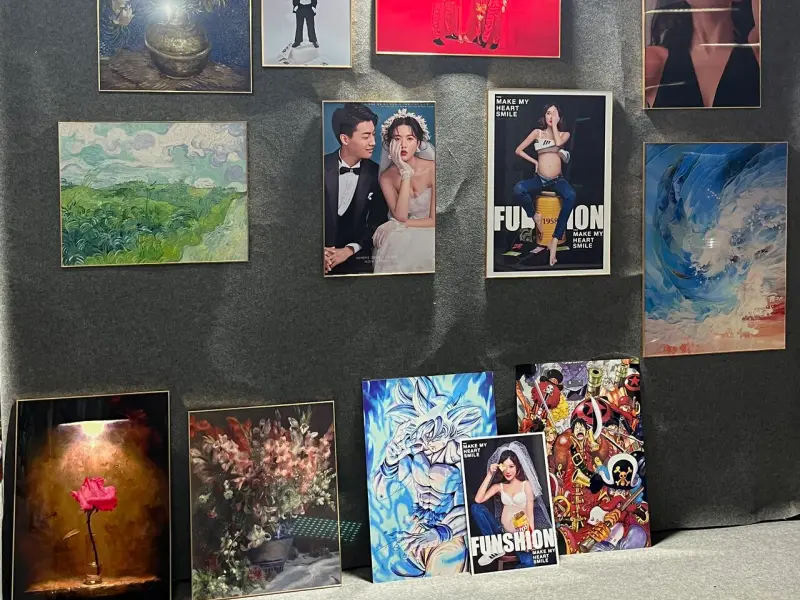

Advantages of Dye Sublimation on Aluminum

- No fading — colors remain bright for years

- Resistant to scratches, moisture, and UV light

- Suitable for both indoor and outdoor displays

- Lightweight yet strong aluminum base

- Eco-friendly and non-toxic process

- Easy cleaning without damage

Applications of Aluminum Dye Sublimation

Sublimation aluminum is widely used across creative and commercial fields:

- Photo panels for professional photographers

- Wall art and home decoration

- Signboards and nameplates

- Display panels for exhibitions

- Custom gifts and souvenirs

- ID cards and awards

- Corporate branding items

Common Sizes for Application:

| Size | Use |

|---|---|

| A4 (210×297 mm) | Small photo printing, signage |

| A3 (297×420 mm) | Wall panels, personalized gifts |

| 12×18 inch | Medium wall décor |

| 24×36 inch | Large commercial displays |

Comparison: Dye Sublimation vs UV Printing

| Feature | Dye Sublimation | UV Printing |

|---|---|---|

| Durability | Long-term, fade-resistant | Moderate |

| Image Depth | Deep and vivid | Surface-level only |

| Scratch Resistance | Excellent | Medium |

| Finish | Glossy or matte | Mostly matte |

| Cost | Economical for bulk | Higher per piece |

| Best for | Photos, art, signage | Prototypes, labels |

How to Choose the Right Sublimation Aluminum Sheet

When selecting aluminum for sublimation, consider:

- Coating quality – polymer coating ensures strong dye absorption

- Thickness – thinner sheets for signage, thicker for photo panels

- Finish – glossy for bright images, matte for soft tones

- Color base – white for true color accuracy

Recommended Alloys:

- 1050 / 1060: For general sublimation

- 5052: For premium strength and corrosion resistance

Dye Sublimation Heat Transfer Equipment

To perform dye sublimation heat transfer on aluminum, you need:

- Sublimation printer (Epson, Sawgrass)

- Sublimation ink and paper

- Heat press machine

- Protective sheet or Teflon film

- Pre-coated aluminum sheet

RFQ – Request for Quotation

If you’re looking to buy sublimation aluminum sheets in bulk, you can send an RFQ (Request for Quotation).

Provide the following details to get an accurate price:

| Item | Required Details |

|---|---|

| Product | Sublimation aluminum sheet |

| Size | A4, A3, 12×18”, 24×36”, etc. |

| Thickness | 0.45mm–1.2mm |

| Finish | Glossy / Matte / Brushed / White |

| Quantity | MOQ 100 pcs or more |

| Packaging | Carton or wooden box |

| Destination | Country or port name |

For large-volume orders, FASTARRIVER Aluminum offers factory-direct prices, OEM packaging, and fast shipping.