Aluminum for sublimation printing is the perfect material for creating vibrant, durable prints. Specially coated aluminum sheets allow sublimation ink to bond permanently, producing stunning results for photos, signs, and artwork.

Why Choose Aluminum for Sublimation Printing?

Aluminum offers unique advantages for sublimation printing:

Key Benefits:

- Excellent Color Reproduction: White polymer coating makes colors pop

- Durability: Scratch-resistant and waterproof surface

- Professional Finish: Modern glossy or matte appearance

- Lightweight: Easy to handle and display

- Longevity: Prints last for decades without fading

Aluminum Printing | Dye Sublimation Process

The dye sublimation process transforms aluminum sheets into permanent prints:

| Process Step | Description | Key Points |

|---|---|---|

| Design Preparation | Create mirror image of your design | Use 300+ DPI resolution for best quality |

| Printing | Print on sublimation paper with special ink | Ensure even ink coverage and let dry |

| Heat Pressing | Transfer design to aluminum using heat | Follow temperature and time guidelines |

| Finishing | Remove paper and inspect results | Peel while warm for best results |

Required Materials:

- Coated aluminum sheets

- Sublimation ink and paper

- Heat press machine

- Heat-resistant tape

- Protective paper

Aluminum Sheet Printing: Types and Specifications

Different aluminum sheets work best for various applications:

| Sheet Type | Coating | Thickness | Best Applications |

|---|---|---|---|

| White Glossy | Polymer coating | 0.8mm-3.0mm | Photos, vibrant artwork |

| White Matte | Matte polymer | 0.8mm-3.0mm | Portraits, text displays |

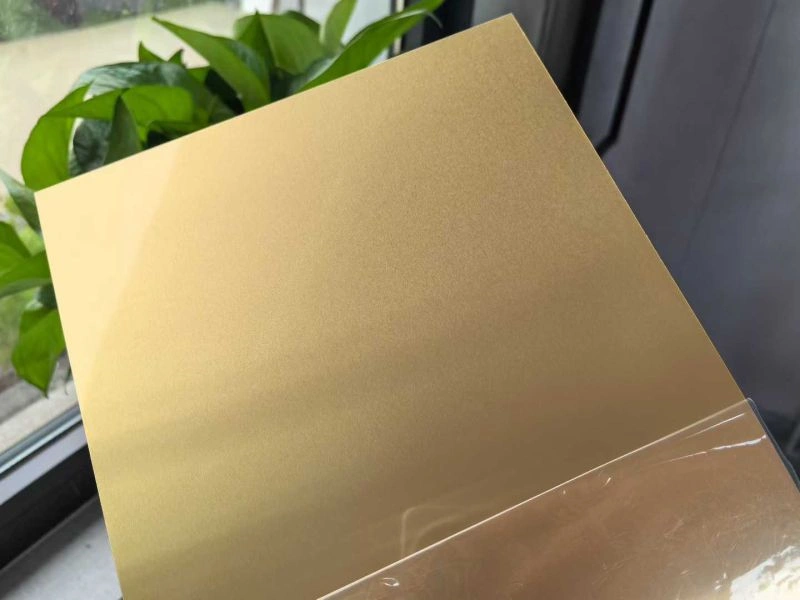

| Silver Metallic | Clear coating | 1.0mm-2.0mm | Modern designs, logos |

| Brushed Metal | Clear coating | 1.5mm-3.0mm | Industrial look, decor |

Standard Sizes Available:

- Small: A4, 8×10 inches, 12×12 inches

- Medium: 16×20 inches, 18×24 inches

- Large: 24×36 inches, 36×48 inches

Sublimation Aluminium Blanks: Ready-to-Use Panels

Pre-cut aluminum blanks simplify the printing process:

Popular Blank Sizes and Uses:

| Size | Common Uses | Weight | Price Range |

|---|---|---|---|

| A4 (8.3×11.7 in) | Documents, small photos | 150g | $3-5 |

| 8×10 inches | Single photos, small art | 120g | $2-4 |

| 12×18 inches | Portraits, medium prints | 280g | $6-9 |

| 16×20 inches | Large artwork, signs | 450g | $10-15 |

Blank Features:

- Pre-coated with polymer layer

- Cut to precise dimensions

- Smooth, ready-to-print surface

- Protective film on some products

Aluminium Sublimation:

Understanding the technical aspects ensures better results:

Material Requirements:

- Aluminum Grade: 3003 or 5052 alloy recommended

- Coating Thickness: 15-25 microns polymer coating

- Surface Finish: Even, smooth coating essential

- Flatness: Must be perfectly flat for even pressure

Quality Indicators:

- Consistent white background color

- No visible scratches or defects

- Even coating across entire surface

- Proper packaging to prevent damage

Sublimation Heat Press: Machine Guide

Choosing the right heat press is crucial for success:

| Press Type | Size Range | Best For | Price Range |

|---|---|---|---|

| Clamshell | Up to 16×20 inches | Beginners, small projects | $300-600 |

| Swing-Away | Up to 24×36 inches | Professionals, larger work | $600-1,500 |

| Calendar | 40+ inches | Commercial production | $2,000+ |

Heat Press Features to Consider:

- Digital temperature control

- Even pressure distribution

- Timer with automatic shut-off

- Large enough for your projects

Temperature and Time Settings

Proper settings ensure perfect transfers:

| Aluminum Thickness | Temperature | Time | Pressure |

|---|---|---|---|

| 0.8mm | 385°F (196°C) | 50-60 seconds | Medium |

| 1.5mm | 395°F (202°C) | 60-70 seconds | Medium |

| 3.0mm | 400°F (204°C) | 75-90 seconds | Firm |

Pro Tips:

- Always do a test print first

- Use Teflon sheet for protection

- Preheat thicker aluminum sheets

- Maintain consistent pressure

Applications of Aluminum Sublimation Printing

Photo and Art Applications:

- Professional photo displays

- Gallery artwork and reproductions

- Personalized photo gifts

- Wedding and portrait photography

Commercial Uses:

- Business signs and nameplates

- Retail displays and point-of-sale

- Trade show graphics

- Office decor and signage

Personal Projects:

- Home decor and wall art

- Personalized gifts and awards

- Craft projects and hobbies

- Custom kitchen and home items

FAQ: Aluminum Sublimation Printing

Q1: What type of aluminum works for sublimation?

A: Only aluminum with special polymer coating works. Regular aluminum won’t accept sublimation ink.

Q2: Can I use any heat press for aluminum sublimation?

A: Yes, but swing-away presses work best for even pressure on larger sheets.

Q3: How durable are sublimated aluminum prints?

A: Very durable – they resist scratching, fading, and moisture. Can last 50+ years indoors.

Q4: What’s the difference between glossy and matte aluminum?

A: Glossy has shiny finish that enhances colors; matte has non-reflective surface better for text.

Q5: Can I sublimate on both sides of aluminum?

A: Yes, if both sides are coated. Most sheets are coated on one side only.

Q6: How do I clean sublimated aluminum?

A: Use soft cloth with mild soap and water. Avoid abrasive cleaners.

Troubleshooting Common Issues

| Problem | Cause | Solution |

|---|---|---|

| Faded Colors | Low temperature or time | Increase temperature by 10°F or time by 15 seconds |

| Blurry Image | Paper movement | Use heat-resistant tape to secure paper |

| Yellowing | Too much heat | Reduce temperature by 15°F |

| Uneven Transfer | Uneven pressure | Check press calibration and aluminum flatness |

Cost Analysis

Startup Costs:

- Heat press: $300-1,500

- Sublimation printer: $400-1,000

- Aluminum blanks: $2-20 per sheet

- Inks and paper: $100-300 initial investment

Ongoing Costs per Print:

- Aluminum sheet: $2-15

- Ink and paper: $0.50-2.00

- Electricity: $0.10-0.50

- Labor: Varies by project

Why Choose Aluminum Over Other Materials?

Comparison Table:

| Feature | Aluminum | Ceramic | Wood | Paper |

|---|---|---|---|---|

| Durability | Excellent | Good | Fair | Poor |

| Color Vibrancy | Best | Very Good | Good | Excellent |

| Cost | Medium | Low | Low | Low |

| Professional Look | Best | Good | Fair | Good |

Getting Started with Aluminum Sublimation

Beginner’s Checklist:

- Choose right aluminum blanks for your project

- Calibrate heat press temperature

- Test with small pieces first

- Use high-resolution images

- Follow manufacturer’s guidelines

Recommended Starter Kit:

- 5-10 assorted aluminum blanks

- Basic heat press (15×15 inch minimum)

- Sublimation ink and paper

- Heat-resistant tape

- Protective paper sheets

Aluminum for Sublimation Printing for professional printing projects

Aluminum for sublimation printing offers unmatched quality and durability for both personal and professional projects. With the right materials, equipment, and techniques, you can create stunning metal prints that last for decades. Start with small projects to master the process, then expand to larger productions as you gain experience.

Ready to begin? Contact us for materials and expert advice!

Keywords: aluminum for sublimation printing, aluminum sheet printing, sublimation aluminium blanks, sublimation heat press, aluminium sublimation

Leave a Reply

You must be logged in to post a comment.