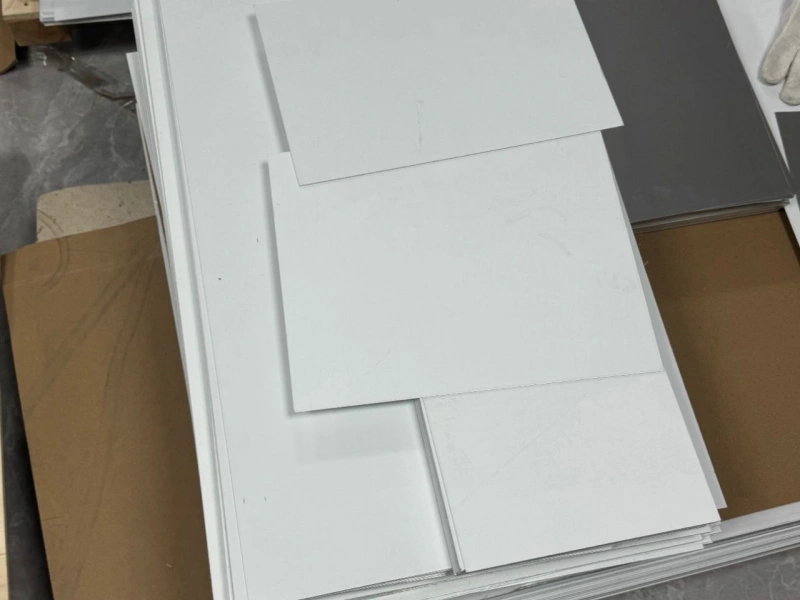

A pearlized white sublimation sheet is a popular material for creating high-quality personalized products. Its glossy pearl-like surface makes colors vibrant, while the strong aluminum base ensures durability. This product is widely used in signage, photo panels, nameplates, and decoration projects.

At FASTARRIVER ALUMINUM, we supply different sizes, thicknesses, and alloys to meet your needs.

Classification of Pearlized Sublimation Sheets

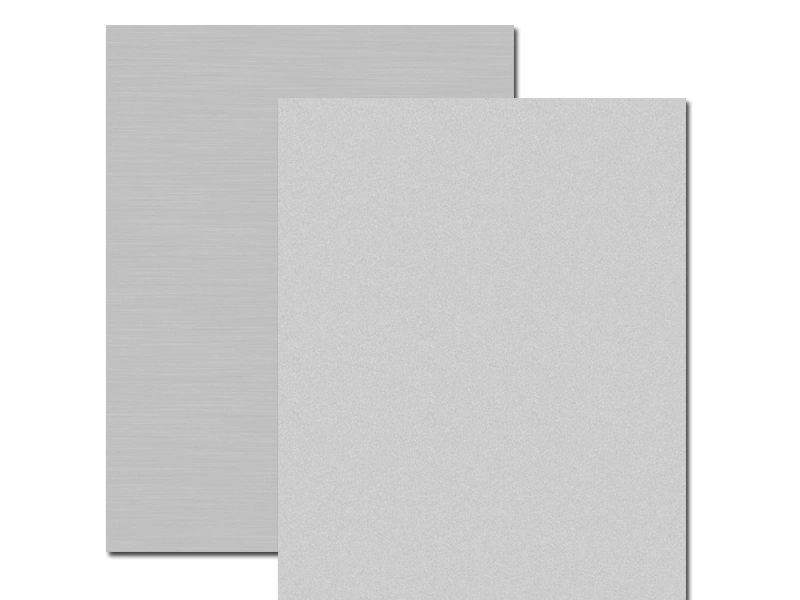

Pearlized sublimation sheets are available in different finishes and grades:

- Glossy white pearlized sheet – best for photo panels.

- Matte pearlized sheet – suitable for signs and nameplates.

- Brushed pearlized sheet – decorative panels and tags.

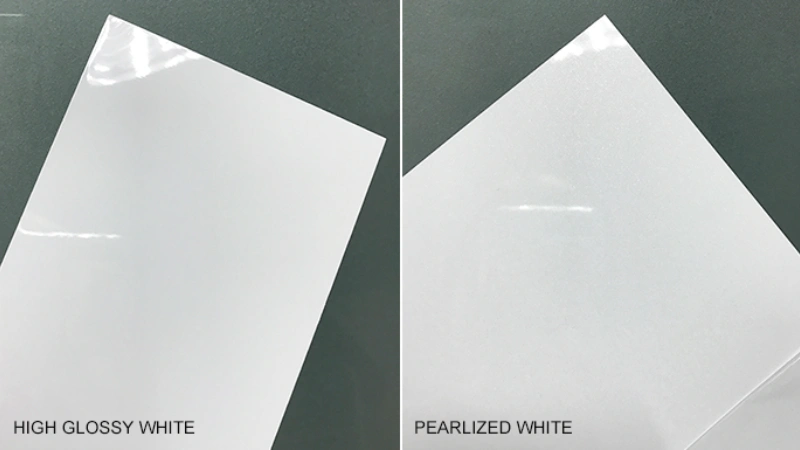

High Glossy White Aluminum Sublimation Sheet vs. Pearlized White Sublimation Sheet

High Glossy White Aluminum Sublimation Sheet

- Smooth, mirror-like white coating

- Produces bright, vivid, and sharp images

- Ideal for photo printing, signage, and decorative panels

- Modern and clean look, perfect for high-end applications

Pearlized White Sublimation Sheet

- Unique pearl shimmer surface with soft reflection

- Creates elegant, textured, and luxurious appearance

- Great for gift items, premium signs, nameplates, and decorative art

- More artistic and stylish compared to glossy finish

✅ Key Difference:

- Glossy = Bright & vivid finish

- Pearlized = Elegant & textured look

Thickness Options

| Thickness (mm) | Common Use Cases |

|---|---|

| 0.3 mm | Lightweight signage, labels, tags |

| 0.5 mm | Photo panels, indoor decoration |

| 0.7 mm | Durable signage, awards, plaques |

| 1.0 mm | Long-lasting outdoor signs, display boards |

Alloy Types

| Alloy | Properties | Applications |

|---|---|---|

| 1050 | High purity, good corrosion resistance | Labels, crafts |

| 1060 | Easy processing, lightweight | Sublimation photo panels |

| 3003 | Better strength, good durability | Signage, display |

| 5052 | High strength, excellent corrosion resistance | Outdoor signs, industrial use |

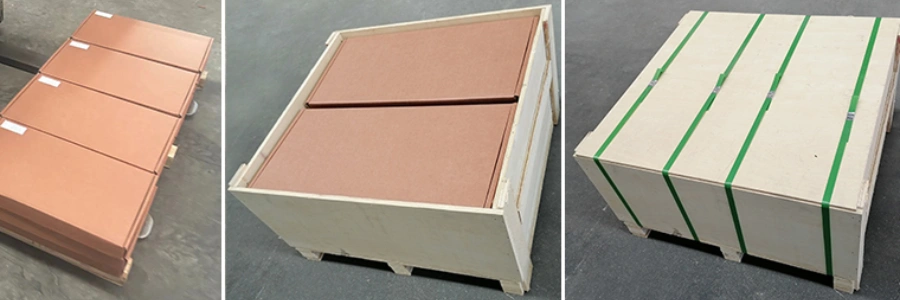

Packaging

Pearlized sublimation sheets are packaged carefully to avoid scratches and bending.

- Standard packing: Protective PE film + carton + wooden pallet

- Custom packing: According to customer needs

- Export standard: Safe for long-distance shipping

Advantages of Pearlized White Sublimation Sheets

- Glossy finish makes colors look vibrant and detailed.

- Durable aluminum base ensures long-term use.

- Scratch-resistant surface maintains a professional look.

- Easy sublimation process with clear image transfer.

- Available in multiple thicknesses and alloys.

Applications of Pearlized Sublimation Sheets

Pearlized white sublimation sheets are widely used in different industries:

- Photo printing – custom photo panels, wall art

- Awards and plaques – certificates, medals, recognition items

- Signage – advertising boards, direction signs

- Decorative panels – wall decorations, interior design

- Nameplates and labels – durable identification tags

Technical Specifications Table

| Item | Specification |

|---|---|

| Product Name | Pearlized White Sublimation Sheet |

| Available Thickness | 0.3 mm, 0.5 mm, 0.7 mm, 1.0 mm |

| Alloy Options | 1050, 1060, 3003, 5052 |

| Surface Finish | Glossy, Matte, Brushed Pearlized |

| Size Range | A4, A3, 600×1200 mm, Custom sizes |

| Packaging | PE Film + Carton + Wooden Pallet |

| Applications | Sublimation photo panels, signage, labels, awards, decoration |

Chossing Pear white sublimation sheet

Choosing a pearlized white sublimation sheet is the right decision for businesses and creators who want long-lasting, vibrant, and professional-quality sublimation products. At FASTARRIVER ALUMINUM, we provide different thicknesses, alloys, and custom sizes to meet your project requirements.

If you are looking for a reliable supplier of sublimation sheets, contact us today for more details.

Technical Specifications

| Parameter | Specification | Testing Standard |

|---|---|---|

| Whiteness Index | 90-95% | ISO 11475 |

| Gloss Level | 20-40 GU | ISO 2813 |

| Sublimation Temperature | 180-200°C | – |

| Sublimation Time | 45-60 seconds | – |

| Coating Hardness | ≥3H | Pencil hardness test |

Printing Guidelines

- Design Preparation:

- Use high-resolution images

- Consider pearl effect in color choices

- Mirror image before printing

- Printing Process:

- Use sublimation ink only

- Ensure proper ink coverage

- Allow adequate drying time

- Heat Press Settings:

- Temperature: 185-195°C

- Time: 50-60 seconds

- Pressure: Medium consistent

- Post-Processing:

- Cool completely before handling

- Remove protective film carefully

- Inspect for uniform transfer

Comparison with Other Sublimation Sheets

| Feature | Pearlized White | Glossy White | Matte White |

|---|---|---|---|

| Surface Effect | Pearlescent shimmer | High gloss | Non-reflective |

| Color Vibrancy | Enhanced depth | Maximum brightness | Soft, muted tones |

| Fingerprint Resistance | Good | Poor | Excellent |

| Best For | Premium applications | General purpose | Art reproductions |

| Cost | Higher | Medium | Medium |

Quality Assurance

All sheets undergo rigorous testing:

✔ Thickness tolerance ±0.05mm

✔ Surface smoothness verification

✔ Color consistency checks

✔ Coating adhesion testing

✔ Packaging integrity inspection

Environmental Performance

| Environment | Suitability | Expected Lifespan |

|---|---|---|

| Indoor Controlled | Excellent | 8-10 years |

| Indoor General | Very Good | 6-8 years |

| Outdoor Protected | Good | 3-4 years |

| Direct Outdoor | Fair | 2-3 years |

Maintenance and Care

- Cleaning:

- Use soft microfiber cloth

- Mild detergent if needed

- Avoid abrasive materials

- Storage:

- Keep in dry environment

- Store flat to prevent bending

- Avoid extreme temperatures

- Handling:

- Wear gloves to prevent fingerprints

- Support large sheets properly

- Handle edges carefully

FAQ

Q: Can pearlized sheets be used outdoors?

A: Yes, but for prolonged outdoor use, choose thicker sheets and apply protective coating.

Q: How does the pearl effect affect print quality?

A: It enhances color depth and creates unique visual effects without reducing sharpness.

Q: Are these sheets recyclable?

A: Yes, the aluminum base is fully recyclable.

Q: Can I cut these sheets myself?

A: Yes, but use appropriate tools and wear safety equipment.

Q: What is the minimum order quantity?

A: Typically 25 sheets for standard sizes.