Aluminum sublimation sheets have become a game-changer in the world of custom printing and product creation. Their unique ability to transform digital images into vibrant, durable, and long-lasting metal prints has opened up a vast array of creative and commercial uses. If you’re looking to create stunning personalized items or robust commercial products, understanding the wide-ranging aluminum sublimation sheet application areas is key.

Top Application Categories

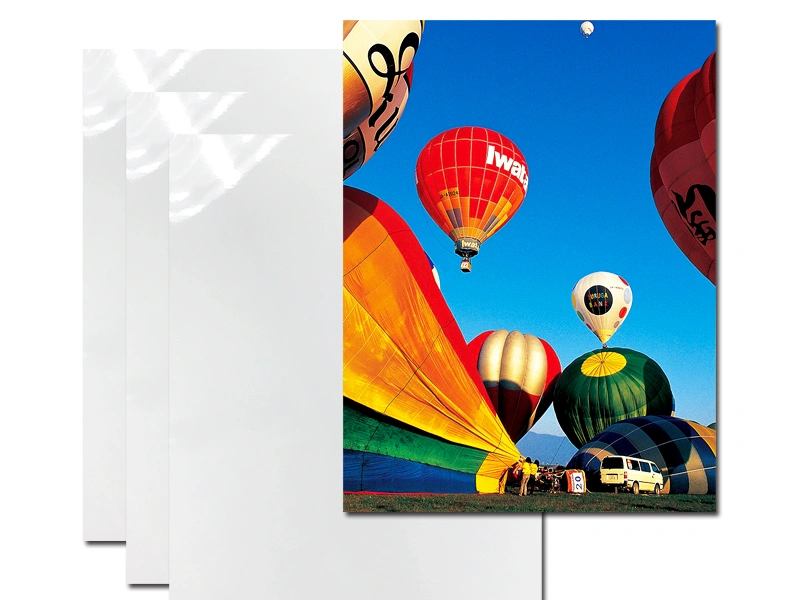

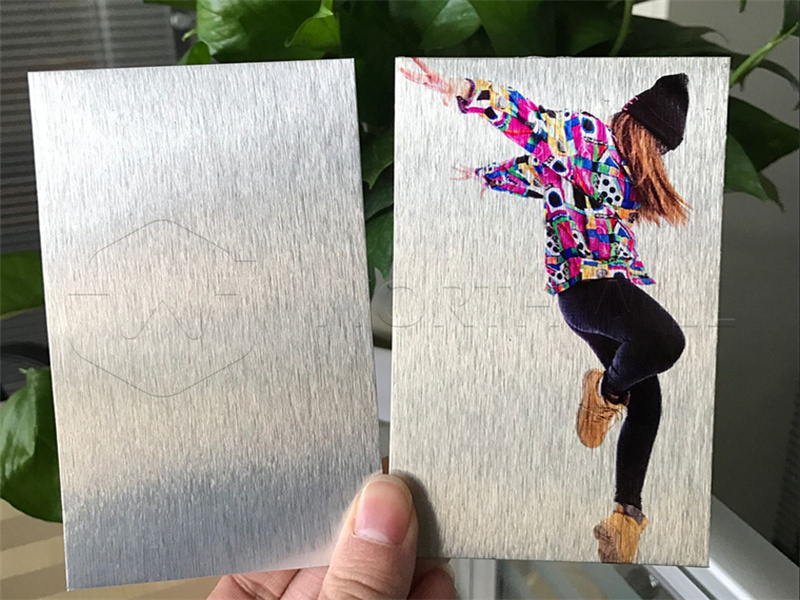

1. Photo & Art Displays

- Wall Art:

- Metal photo panels

- Gallery-style collections

- Canvas alternatives

- Special Occasions:

- Wedding portraits

- Anniversary gifts

- Pet memorials

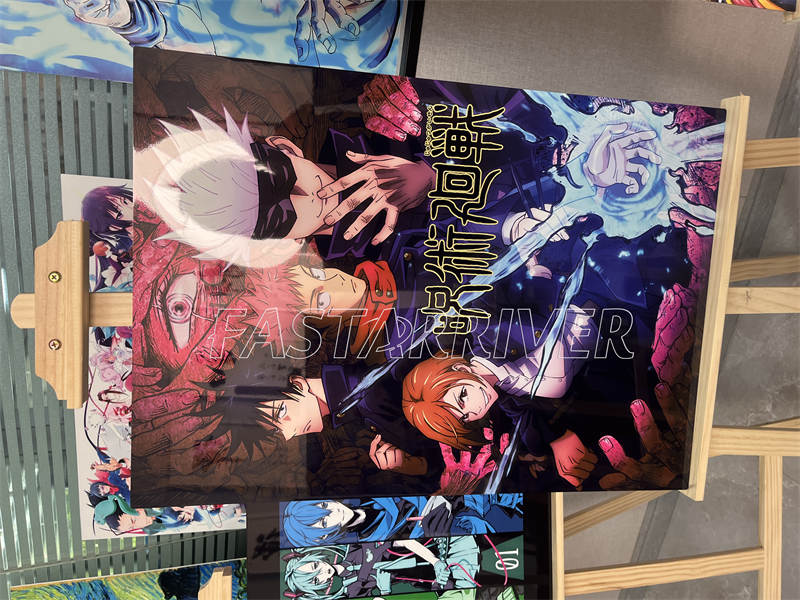

- Creative Projects:

- Mixed media art

- Photo collages

- Limited edition prints

2. Business & Retail Signage

| Type | Benefits |

|---|---|

| Storefront signs | Weather-resistant |

| Menu boards | Easy to clean |

| Price tags | Scratch-proof |

| Directional signs | Lightweight |

3. Promotional Products

- Corporate Gifts:

- Award plaques

- Branded magnets

- Executive desk items

- Event Giveaways:

- Commemorative plates

- Sponsor recognition

- Trade show freebies

4. Industrial Uses

- Equipment Labels:

- Machinery identification

- Safety instructions

- Maintenance logs

- Control Panels:

- Button labels

- Diagram overlays

- Warning signs

Application-Specific Specifications

| Application | Recommended Thickness | Best Alloy | Special Requirements |

|---|---|---|---|

| Wall art | 1.0-1.5mm | 3003 | Matte/gloss coating |

| Outdoor signs | 1.5-2.0mm | 5052 | UV-resistant laminate |

| Promo items | 0.8-1.2mm | 3003 | Edge rounding |

| Industrial labels | 0.5-1.0mm | 6061 | Chemical-resistant coating |

Creative Techniques

1. Multi-Panel Designs

- Create panoramic displays

- Build geometric wall arrangements

- Develop storyboard sequences

2. Special Effects

- Holographic finishes: Use specialty transfer papers

- Texture overlays: Combine with embossing

- Glow elements: Add phosphorescent layers

3. Functional Combinations

- Magnet-backed business cards

- Dry-erase compatible schedules

- QR code integrated artwork

Industry-Specific Uses

1. Hospitality

- Restaurant menu boards

- Hotel room numbers

- Resort wayfinding signs

2. Healthcare

- Patient room identifiers

- Medical equipment labels

- Sanitation instruction signs

3. Education

- Classroom visuals

- Award certificates

- Campus donor recognition

4. Automotive

- Showroom displays

- Custom car art

- Garage organization signs

Comparison to Alternative Materials

| Application | Aluminum Advantage |

|---|---|

| Outdoor signage | More durable than acrylic |

- Photo displays | Lighter than glass/metal prints |

- Industrial labels | More chemical-resistant than plastic |

- Retail signs | More premium than PVC |

Success Tips

- Surface Prep: Always clean with isopropyl alcohol

- Press Settings: 190°C for 60-90 seconds

- Design Considerations:

- Allow 3mm bleed

- Use 300 DPI resolution

- Convert text to outlines

- Post-Press Care:

- Cool completely before handling

- Apply protective laminate for outdoor use

- Store vertically to prevent scratching

FAQ

Q: Can you sublimate both sides?

A: Yes – use double-sided coated sheets

Q: How to hang metal prints?

A: Use adhesive strips, French cleats, or standoffs

Q: Minimum order quantities?

A: Often 10+ sheets for custom work

Q: Outdoor lifespan?

A: 3-5 years with UV laminate protection

Main Features

- High Durability – Resistant to fading, scratches, and water.

- Lightweight – Easy to handle and install.

- Smooth Surface – Ensures detailed and clear printing.

- Multiple Sizes – Commonly available in A4, A3, and custom dimensions.

How to Use

- Choose your desired image or design.

- Print it on sublimation paper with sublimation ink.

- Place the paper on the aluminum sheet.

- Apply heat press according to the recommended time and temperature.

- Remove the paper and allow the sheet to cool.