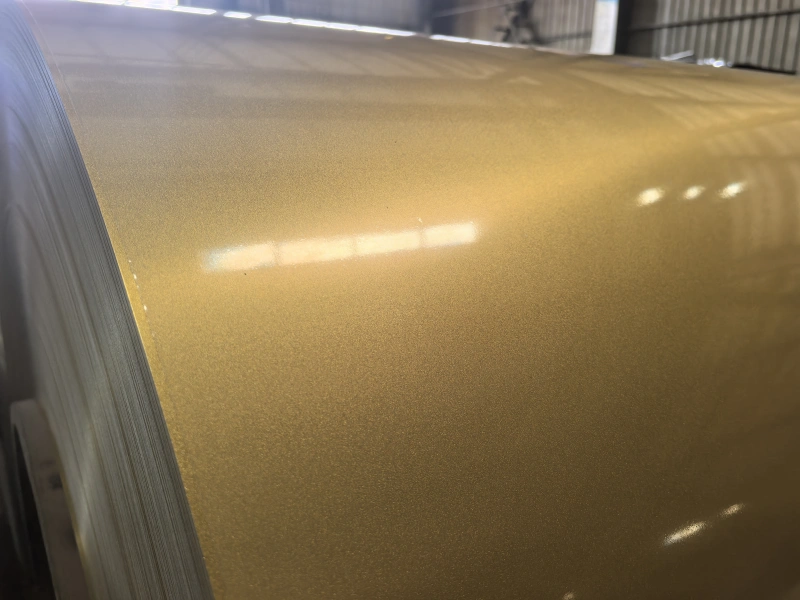

Sublimation aluminum sheet is specially coated metal panels designed for heat transfer printing. They offer a smooth surface for clear, vibrant, and durable images, making them ideal for personalized signs, photo panels, and promotional items.

Specification

| Specification | Details |

|---|---|

| Classification | Glossy white, matte white, brushed silver, brushed gold |

| Thickness | 0.3 mm, 0.4 mm, 0.5 mm, 0.55 mm, 0.7 mm |

| Alloy | 1050, 1060, 1100, 3003 |

| Size | A4, A3, 12″x24″, custom sizes |

| Packaging | Protective film + carton box + pallet |

| Surface Coating | Polyester or PET sublimation coating |

Aluminum Alloy Specifications

| Alloy | Characteristics | Sublimation Performance |

|---|---|---|

| 1050 | Soft, economical | Good for flat applications |

| 3003 | Standard strength | Best all-purpose choice |

| 5052 | Marine-grade | Excellent for outdoor use |

| 6061 | Structural | Overkill for most printing |

*Most common: 3003-H14 alloy*

Thickness

The thickness of sublimation aluminium sheet is a critical specification, impacting the material’s rigidity, weight, and the overall durability of the final product. It is typically measured in millimeters (mm) or inches.

| Thickness (mm) | Thickness (inches) | Typical Applications of Sublimation Aluminum Sheet |

|---|---|---|

| 0.45 mm | 0.018″ | Lightweight interior signage, decorative panels, thin photo prints |

| 0.5 mm | 0.020″ | Standard photo panels, small plaques, indoor informational signs |

| 0.65 mm | 0.025″ | Light duty interior signs, craft projects, custom product labels |

| 0.75 mm | 0.030″ | Medium-duty indoor/outdoor signs, awards, durable photo prints, name tags |

| 1.0 mm | 0.040″ | Commercial signage, real estate signs, durable displays, art reproductions |

| 1.1 mm | 0.043″ | Premium outdoor signage, architectural panels, structural art pieces |

| 1.5 mm+ | 0.060″+ | Heavy-duty industrial signs, large outdoor billboards, custom fabricated parts |

Choosing the correct thickness ensures that your finished product made from sublimation aluminum sheet possesses the desired structural integrity and aesthetic appeal. Thicker sheets generally offer greater rigidity and a more premium feel.

Key Features

- Smooth coating for high-resolution printing

- Scratch-resistant and durable finish

- UV-resistant colors for long-lasting use

- Available in multiple thicknesses and finishes

- Easy to cut, drill, and shape for custom projects

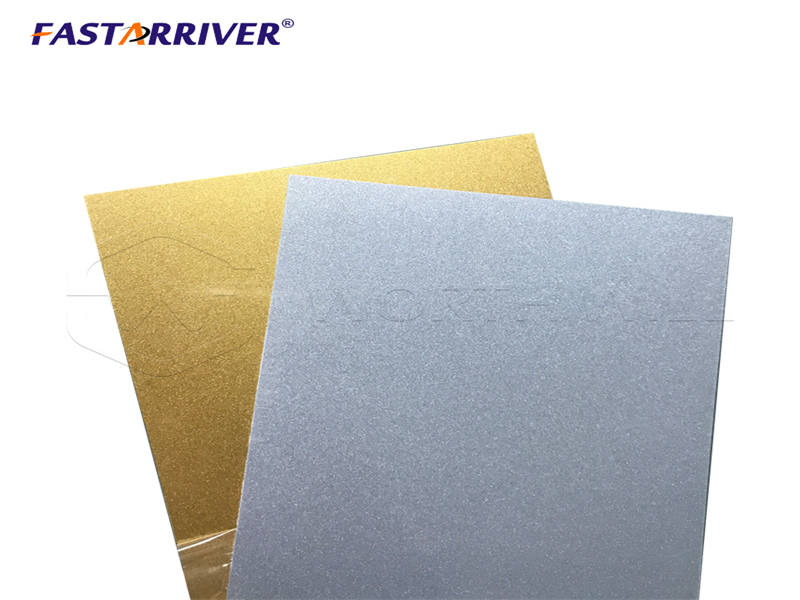

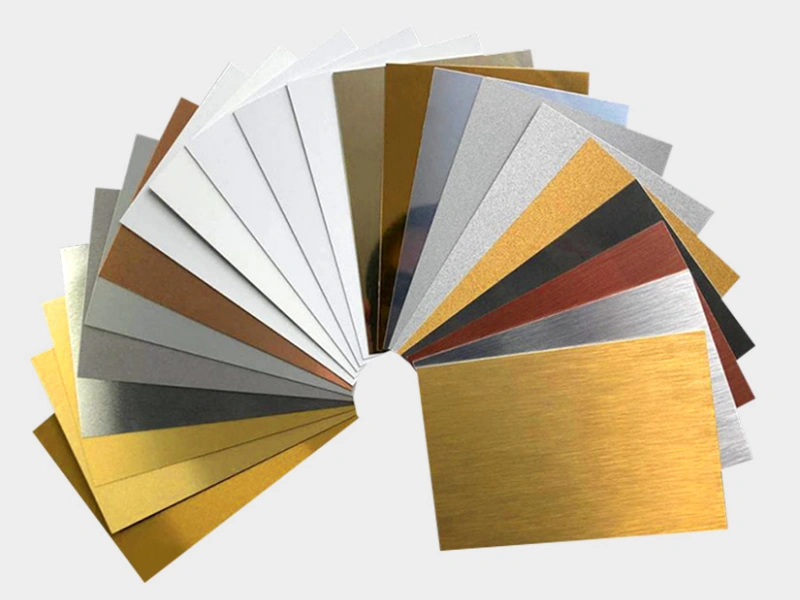

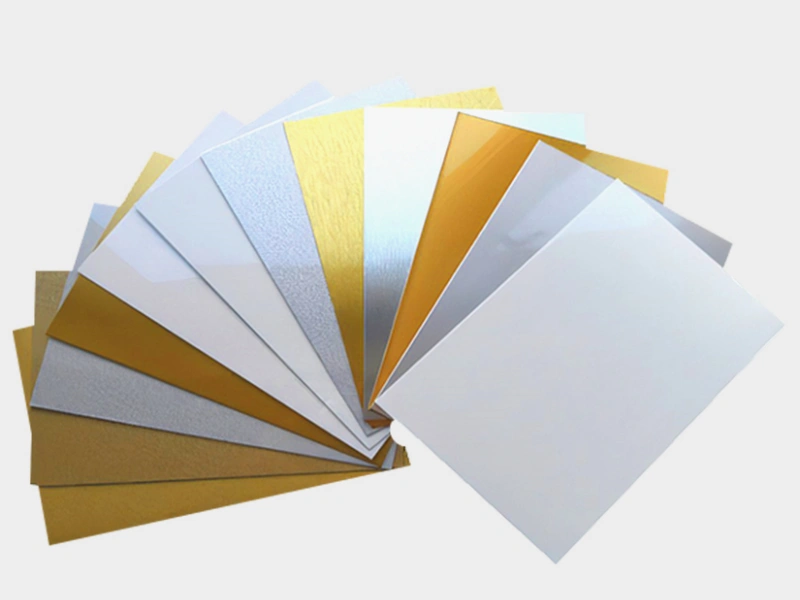

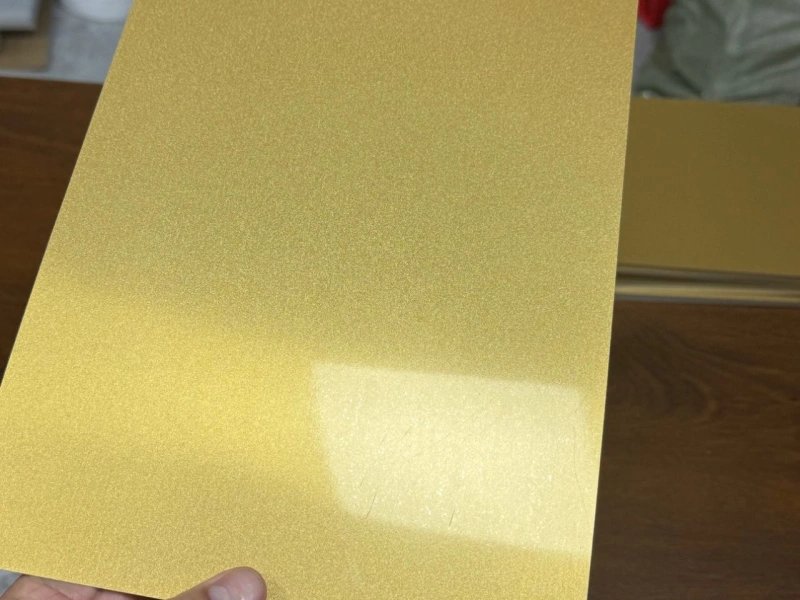

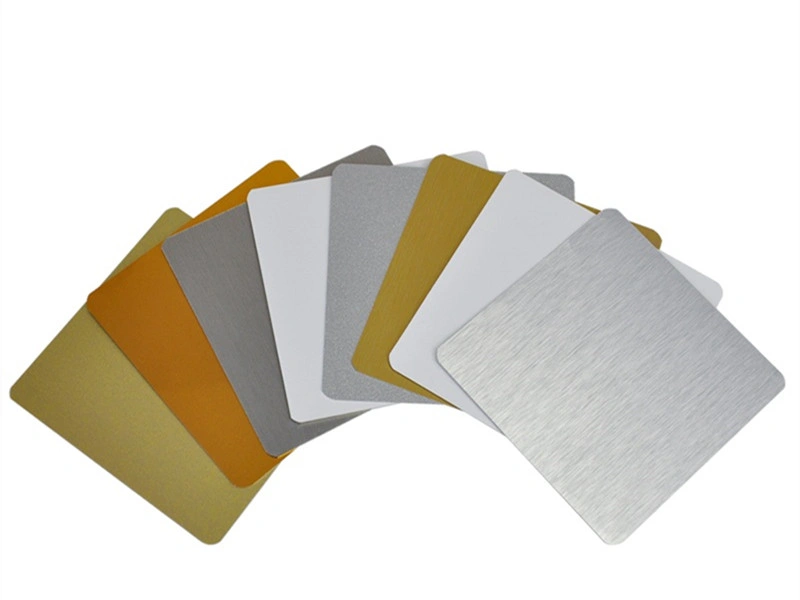

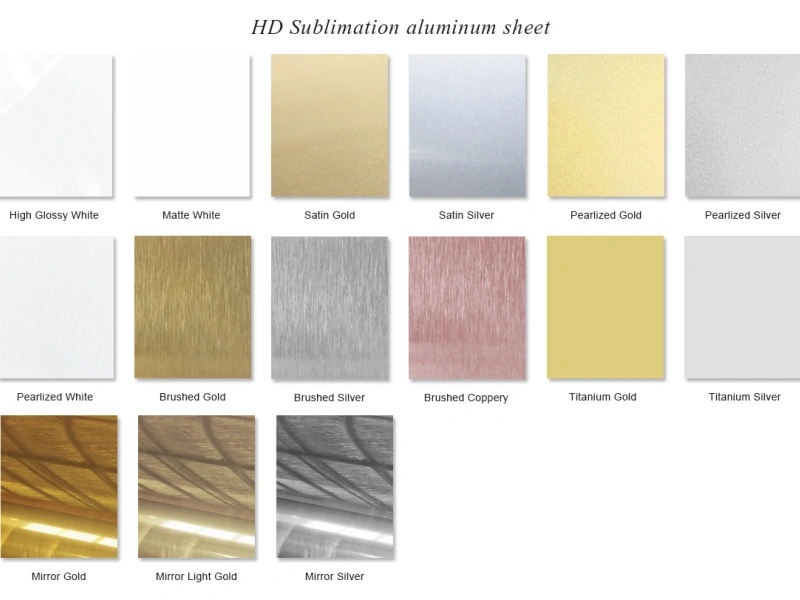

Product Classification

By Finish

- Glossy white sublimation aluminium sheet

- Matte white sublimation aluminum sheet

- Brushed silver sublimation aluminum sheet

- Brushed gold sublimation aluminum sheet

By Thickness

- Thin type: 0.3 mm – 0.4 mm (lightweight, flexible)

- Standard type: 0.5 mm – 0.55 mm (general use)

- Heavy duty: 0.7 mm and above (rigid, long-lasting)

Applications

In various industries:

- Custom photo panels

- Indoor and outdoor signs

- Award plaques

- Door plates and name tags

- Promotional display boards

- Wall decoration panels

- Souvenir products

Sublimation Printing Process

- Design Preparation (300 DPI minimum)

- Sheet Cleaning (alcohol wipe)

- Heat Press Setup (190°C, medium pressure)

- Image Transfer (60-90 seconds)

- Cooling (2 minutes before handling)

Technical Specifications

| Parameter | Specification |

|---|---|

| Sublimation Temperature | 180-200°C |

| Press Time | 45-90 seconds |

| Coating Thickness | 15-25 microns |

| Color Gamut | 95% sRGB |

| Image Permanence | 50+ years indoors |

Quality Comparison

| Feature | Aluminum | Ceramic | Acrylic |

|---|---|---|---|

| Image Quality | Excellent | Very Good | Good |

| Durability | High | Very High | Medium |

| Weight | Light | Heavy | Medium |

| Cost | $$ | $$$ | $$ |

Price Factors (2025)

| Factor | Price Impact |

|---|---|

| Thickness | 2.0mm = +30% vs 1.0mm |

| Quantity | 50+ sheets: 15% discount |

| Coating Type | Matte = +10% vs gloss |

| Custom Sizing | +20-50% |

| Packaging | Individual = +$0.75/sheet |

*Current price range: $8-$50 per sheet*

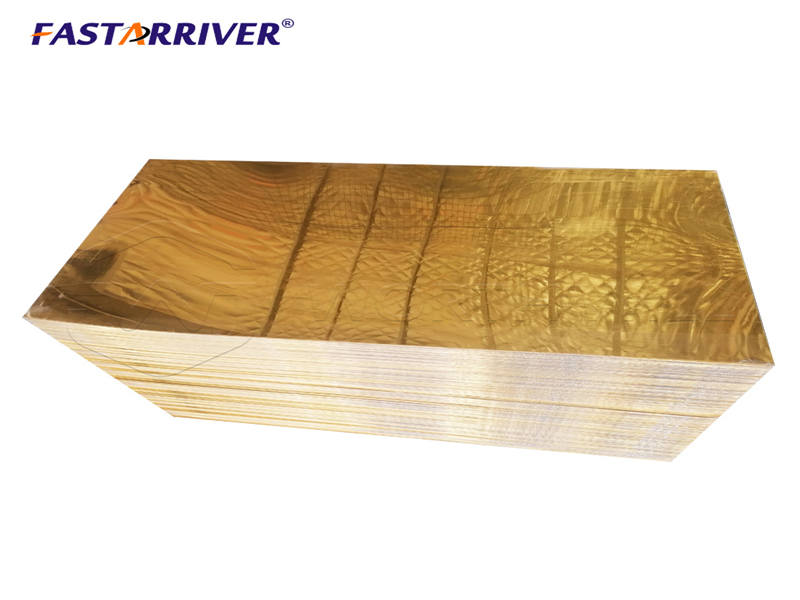

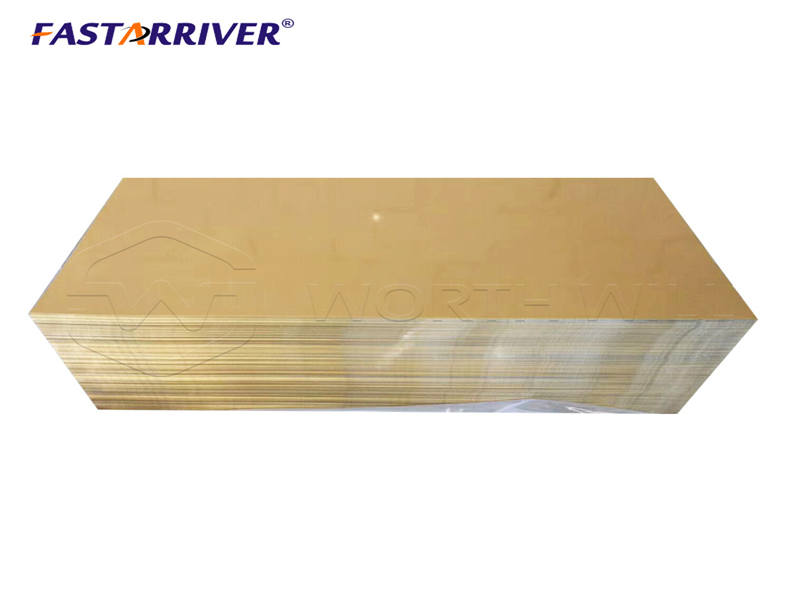

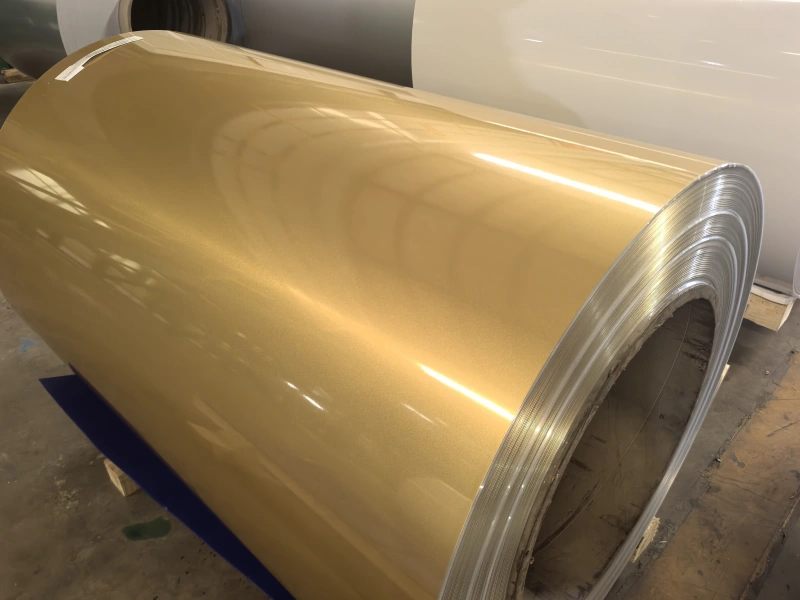

Packaging

- Each sheet covered with protective film to prevent scratches

- Stacked in strong cartons

- Palletized for safe transport

- Custom labeling available

Why Choose Our Sublimation Aluminum Sheet

- Factory-direct pricing for bulk orders

- Consistent coating quality

- Wide size and color selection

- Fast shipping and safe packaging

Frequently Asked Questions (FAQs)

Here are some common questions regarding sublimation aluminium sheet:

Q: Can any aluminum sheet be used for sublimation?

A: No. Only sublimation aluminium sheet specifically pre-treated with a special polyester coating can be used for sublimation. Standard aluminum will not accept the sublimation ink.

Q: What equipment do I need to print on sublimation aluminum sheet?

A: You will need a sublimation printer with sublimation inks, sublimation transfer paper, and a heat press large enough for your sheet size. For cutting, you may need a shear, guillotine, or CNC router.

Q: Is sublimation aluminum sheet suitable for outdoor use?

A: Yes, many types of sublimation aluminum sheet are designed with UV-resistant coatings that make them highly suitable for outdoor applications, offering excellent durability against weather and sun exposure. Always check the specific product specifications.

Q: How durable are prints on sublimation aluminum sheet?

A: Prints on high-quality sublimation sheet are exceptionally durable. Because the ink is infused into the coating, they are resistant to scratches, abrasions, moisture, and fading, often lasting for decades indoors and many years outdoors.

Q: Can I cut sublimation aluminum sheet to custom sizes?

A: Absolutely. Sublimation sheet is specifically designed to be cut and fabricated into custom sizes and shapes using appropriate cutting tools like shears, guillotines, or CNC routers, depending on the thickness and complexity of the cut.