Aluminum sublimation mirror sheets are specially coated aluminum sheets with a high-gloss mirror finish. These sheets are ideal for sublimation printing, offering vibrant image transfer and a shiny metallic surface. Popular for decorative and personalized products, mirror aluminum sheets are available in silver, gold, and custom sizes.

Specification of Aluminum Sublimation Mirror Sheet

- Material: Aluminum alloy (commonly 1050, 1060, 3003)

- Coating: Polyester sublimation coating

- Finish: Mirror silver, mirror gold

- Size Options:

- A4 mirror sublimation aluminum sheet

- 600x400mm sublimation aluminium sheet

- Custom sizes available

- Thickness: 0.3mm – 1.5mm

- Printing Method: Heat transfer sublimation

Classification of Mirror Sublimation Aluminum Sheet

Aluminum sublimation mirror sheets can be classified based on color, size, and finish:

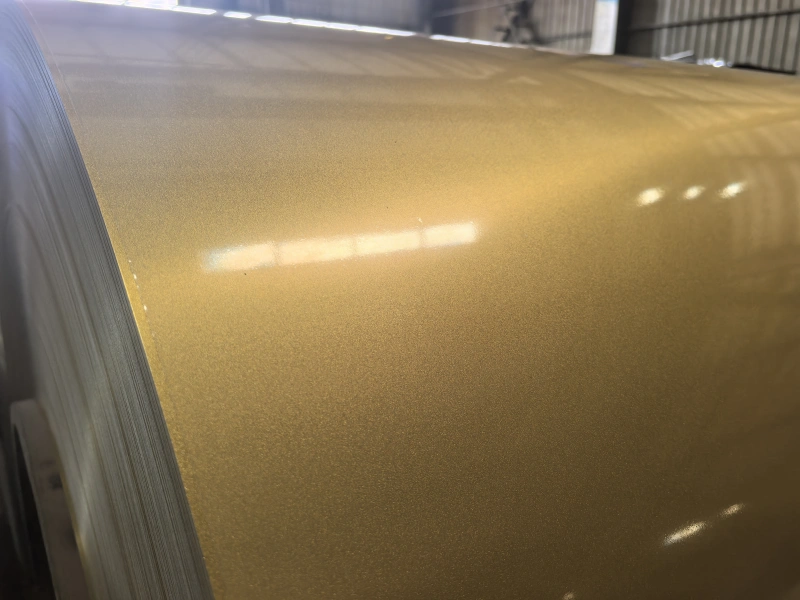

- Mirror Silver Aluminum Sublimation Sheet: Bright silver finish, best for high-contrast images.

- Mirror Gold Sublimation Aluminium Sheet: Warm, luxurious tone for awards and gifts.

- A4 Mirror Sublimation Aluminum Sheet: Ideal for small-format printing.

- 600x400mm Sublimation Aluminium Sheet: Suitable for signage or displays.

- Alloy Types: 1050, 1060 (soft, good for photo panels), 3003 (more rigid for industrial use)

Mirror Gold & Silver Sublimation Aluminum Sheet Case Uses

These aluminum mirror sheets are used for many customized and professional applications. Their reflective surface makes them ideal for:

- Personalized photo gifts

- Custom wall signs

- Luxury product labels

- Event name tags and plaques

- Decorative mirror panels

- Artistic photo reproduction

Create Stunning Visuals with Reflective Brilliance

Welcome to the world of aluminum sublimation mirror sheets, where stunning visuals meet exceptional durability. If you’re looking to create prints that truly stand out, with a reflective, high-gloss finish, then an aluminum sublimation mirror sheet is your ideal material. These unique sheets combine the strength and lightness of aluminum with a specially prepared, mirror-like surface, ready to accept vibrant sublimation prints.

Unlike standard aluminum panels, these mirror sheets offer an unparalleled reflective quality, making images pop with extra depth and luminosity. They are coated with a high-quality polymer, which is essential for the sublimation process. This coating allows the special sublimation inks to permanently fuse with the surface when heat and pressure are applied, resulting in a print that is not just on the surface, but in the surface.

Whether you’re a professional artist, a photographer, or a crafter looking for premium materials, understanding the capabilities of an aluminum sublimation mirror sheet will open up new possibilities. This guide will explore what makes these sheets so special, their various types, and how you can use them to produce truly remarkable results.

What Makes Aluminum Sublimation Mirror Sheets Unique?

The magic of an aluminum sublimation mirror sheet lies in its construction and coating.

The Mirror Finish

The most striking feature is its highly polished, reflective surface. This mirror-like quality makes printed images appear incredibly vivid and almost three-dimensional. Light reflects off the surface, enhancing colors and details, giving your prints a high-end, luxurious look. This reflective quality is what sets a mirror silver aluminum sublimation sheet or a mirror gold sublimation aluminum sheet apart from standard white or brushed aluminum options.

The Sublimation Coating

Underneath the mirror finish, these sheets have a special polymer coating. This clear, durable layer is designed to accept sublimation inks. When heated, the solid inks turn into a gas and permeate this coating. As the sheet cools, the inks solidify within the coating, making the image a permanent part of the aluminum. This process ensures exceptional scratch, water, and UV resistance.

The Aluminum Alloy

The base material of these sheets is a high-quality aluminum alloy. The specific alloy used contributes to the sheet’s rigidity, flatness, and overall durability. Common alloys are chosen for their excellent formability and surface consistency, ensuring a smooth, flawless mirror finish. The strength of the aluminum alloy ensures that your finished product is lightweight yet robust, resisting bending or warping over time.

Types and Sizes of Aluminum Sublimation Mirror Sheets

Aluminum sublimation mirror sheets come in various finishes and sizes to suit different needs and artistic visions.

Mirror Gold & Silver Sublimation Aluminium Sheet

These are perhaps the most popular types due to their stunning aesthetic appeal.

- Mirror Silver Aluminum Sublimation Sheet: This classic choice provides a true mirror reflection, making colors vibrant and adding a sleek, modern touch to any image. It’s perfect for fine art, photography, and contemporary designs.

- Mirror Gold Sublimation Aluminum Sheet: Offering a luxurious, warm reflection, the gold mirror sheet adds an opulent feel to your prints. It’s excellent for awards, high-end signage, or artistic pieces requiring a touch of elegance.

The choice between mirror gold & silver sublimation aluminium sheet depends entirely on the desired aesthetic and the image you plan to transfer. Both offer unparalleled reflective qualities for sublimation aluminum projects.

Common Sizes

These sheets are available in a range of sizes, catering to diverse applications:

- A4 mirror Sublimation Aluminum Sheet: This common paper size (210 x 297 mm or 8.3 x 11.7 inches) is ideal for smaller prints, personal photos, awards, or test runs. Its convenient size makes it popular for desktop sublimation setups.

- 600x400mm Sublimation Aluminium Sheet: A larger format (approximately 23.6 x 15.7 inches), this size is perfect for creating substantial wall art, medium-sized signs, or multiple smaller items that can be cut from a single sheet.

- Other custom sizes are often available from suppliers, allowing for maximum flexibility in your projects.

Consider the final use of your print when choosing the size of your aluminum sublimation mirror sheet.

The Sublimation Process on Mirror Sheets

The process of sublimating onto an aluminum sublimation mirror sheet is similar to other sublimation blanks, but with extra attention to detail to preserve the mirror finish.

- Design and Print: Create your image using graphic design software. Always remember to mirror (flip horizontally) your design before printing! Print your mirrored image onto high-quality sublimation paper using a sublimation printer with sublimation inks.

- Prepare the Sheet: Carefully clean the surface of your aluminum sublimation mirror sheet with a lint-free cloth and a mild cleaner (like rubbing alcohol) to remove any dust, fingerprints, or smudges. Even small particles can affect the mirror finish of your final print.

- Position and Secure: Place your printed sublimation paper (image side down) onto the coated, mirror side of the aluminum sheet. Secure it firmly with heat-resistant tape to prevent any shifting during pressing, which could lead to ghosting.

- Heat Press: Place the taped aluminum sublimation mirror sheet into your heat press. Ensure you use protective paper above and below the sheet to protect your heat press platen and prevent ink bleed-through. The typical temperature for sublimating onto mirror aluminum is around 380-400°F (193-204°C) for 45-75 seconds, but always consult the manufacturer’s recommendations for your specific sheets and inks. Apply medium to firm pressure.

- Cool and Reveal: Once the pressing is complete, carefully remove the hot sheet from the heat press using heat-resistant gloves. Peel off the sublimation paper immediately while it’s still warm to prevent the ink from “re-gassing” back onto the sheet, which can cause blurry edges. Allow the stunning aluminum sublimation mirror sheet to cool completely before handling or framing.

Applications of Aluminum Sublimation Mirror Sheets

The unique aesthetics and robust nature of aluminum sublimation mirror sheets make them suitable for a wide range of applications:

- Premium Photography Prints: Elevate your photos to a new level with stunning depth and vibrancy, perfect for art galleries or high-end home decor.

- Artistic Reproductions: Artists can create brilliant reproductions of their work, with the mirror surface adding a unique dimension.

- High-End Signage: Produce luxurious and durable indoor signs for businesses, hotels, or retail environments.

- Awards and Trophies: Create prestigious and eye-catching awards, plaques, and commemorative items.

- Decorative Panels: Design custom decorative panels for architectural features, furniture inserts, or wall installations.

- Jewelry and Ornaments: Cut into smaller shapes, these sheets can be used to make dazzling custom jewelry pieces, pendants, or ornaments.

- Custom Cases and Display Boxes: The mirror gold & silver sublimation aluminum sheet case concept allows for personalizing luxury packaging or display cases with reflective, vibrant designs, adding a truly bespoke touch.

- Promotional Items: Craft unique and memorable promotional products that truly stand out.

Packaging

Why Choose Mirror Sublimation Aluminum?

Choosing an aluminum sublimation mirror sheet offers numerous advantages:

- Exceptional Visual Impact: The mirror finish creates a depth and luminosity that other materials simply cannot match, making colors more vivid and details sharper.

- Superior Durability: Resistant to scratches, chemicals, moisture, and UV fading, ensuring your prints last for years, even in challenging environments.

- Lightweight and Strong: Aluminum is inherently lightweight, making these sheets easy to handle, hang, and ship, while still being incredibly robust.

- Modern and Elegant: The sleek, reflective surface provides a contemporary and high-end aesthetic, suitable for diverse interior designs and product lines.

- Environmentally Friendly: Aluminum is a highly recyclable material, making it a more sustainable choice for your printing needs.

Tips for Success with Aluminum Sublimation Mirror Sheets

To achieve the best results when working with an aluminum sublimation mirror sheet:

- Handle with Care: The mirror surface is delicate before sublimation. Avoid touching it directly with bare hands to prevent fingerprints or oils from transferring. Use cotton gloves if possible.

- Cleanliness is Key: Ensure your sheet is spotless before pressing. Any dust or fibers will be magnified by the mirror finish.

- Peel Carefully: Always peel the sublimation paper from the sheet while it’s still warm. A steady, even peel is best.

- Test Settings: If you’re new to a specific brand or size of sheet, do a small test print to fine-tune your temperature and time settings.

- Protection during Transport: If you plan to resell or transport the finished prints, ensure they are well-protected to maintain their pristine mirror finish.

Conclusion

The aluminum sublimation mirror sheet is a groundbreaking material that elevates sublimation printing to an art form. Its reflective qualities, combined with the durability of aluminum alloy and the vibrancy of sublimation, allow for the creation of truly breathtaking metal prints.

Whether you opt for the classic elegance of a mirror silver aluminum sublimation sheet or the luxurious appeal of a mirror gold sublimation aluminum sheet, you are investing in a product that promises both visual splendor and lasting quality. From an A4 mirror Sublimation Aluminum Sheet for personal projects to a large 600x400mm Sublimation Aluminium Sheet for professional displays, the possibilities are endless. Embrace the reflective revolution and start creating your own magnificent pieces with aluminum sublimation mirror sheets today!