Aluminum blanks for sublimation are high-quality, coated metal sheets designed for printing custom images and designs using heat and sublimation ink. These blanks are widely used in personalized photo panels, signage, and decorative products. Thanks to their durability and vivid color output, they are one of the top choices for sublimation printing.

Specification of Aluminum Sublimation Blanks

| Feature | Details |

|---|---|

| Material | Pure aluminum (Alloy 1050, 1060, 1100, 3003) |

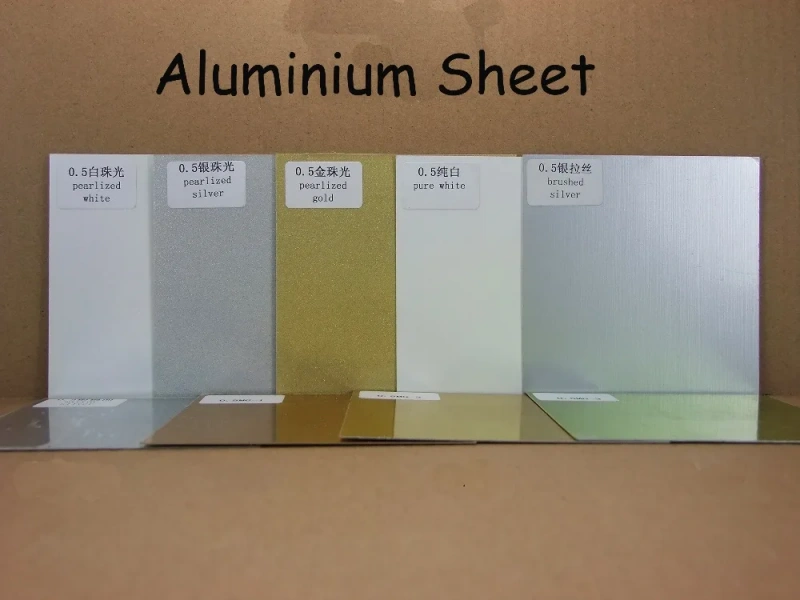

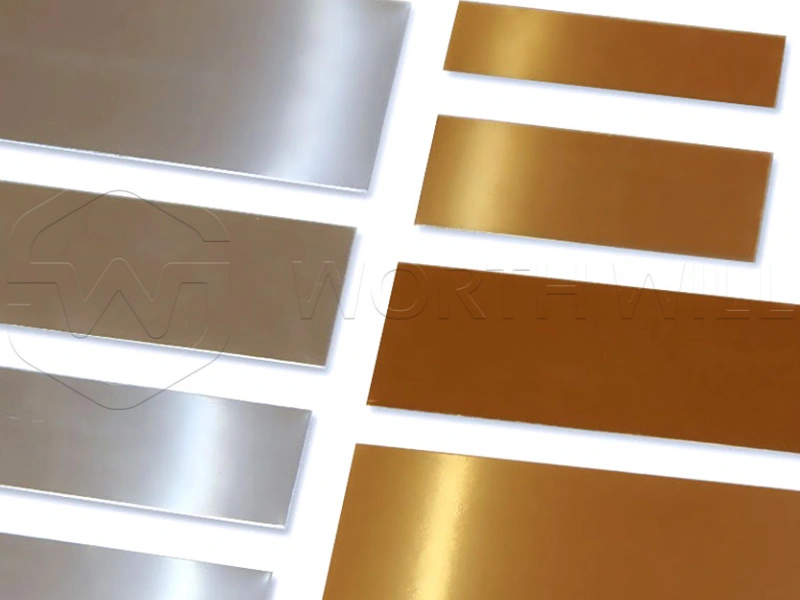

| Thickness | 0.25mm to 1.0mm standard; custom sizes available |

| Surface Finish | Glossy, matte, brushed, pearl, mirror |

| Coating | Sublimation polyester coating |

| Standard Sizes | 12″x18″, 12″x24″, 24″x36″, custom dimensions |

| Corner Options | Square or rounded corners |

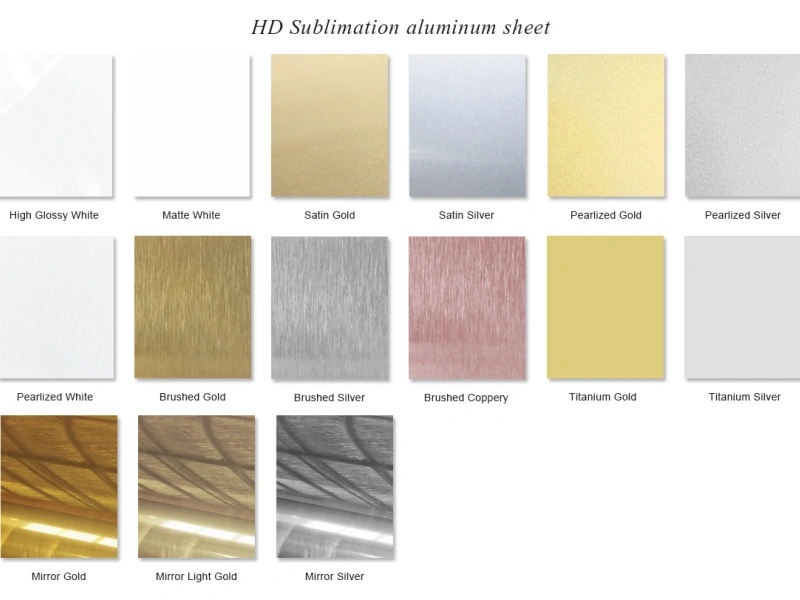

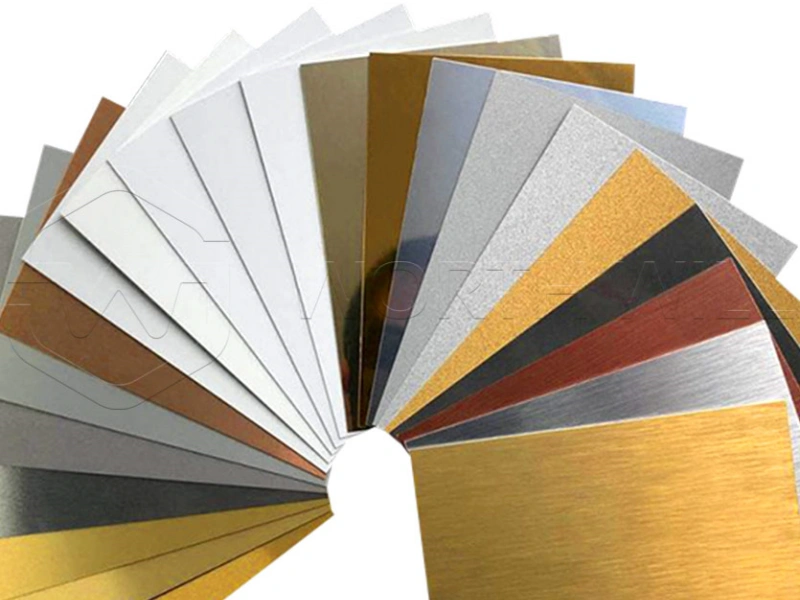

Classification of Aluminum Blanks

Aluminum sublimation blanks can be classified by:

- Finish:

- Glossy white

- Matte white

- Brushed silver or gold

- Mirror finish

- Pearlized surface

- Shape:

- Rectangular panels

- Round discs

- Custom-cut shapes (hearts, ovals, etc.)

- Thickness:

- Thin blanks (0.25mm–0.45mm) for signage or decoration

- Medium (0.65mm–0.8mm) for photo panels

- Heavy-duty (1.0mm and up) for durable outdoor signs

Sublimation Blank 12″ x 18″ Aluminum Photo Panels

One of the most popular sizes is the 12″ x 18″ aluminum photo panel, perfect for:

- Custom wall art

- Memorial plaques

- Business signage

- Personal gifts

This size provides enough space for clear image quality and strong visual impact. The glossy or matte surface allows for brilliant colors, and the metal base ensures long-term use.

Lower Cost for Aluminum Sublimation Blanks

Looking for affordable sublimation blanks? Buying from a manufacturer like our factory helps you reduce cost while ensuring quality.

Tips to Reduce Costs:

- Buy in bulk quantities

- Choose standard sizes for easy processing

- Select lighter thickness for indoor use

- Use pre-cut blanks to save labor

At our facotry, we offer factory-direct pricing, fast lead times, and consistent quality.

Why Choose Aluminum for Sublimation?

Aluminum sublimation blanks are preferred due to:

- Superior print quality: Vivid and sharp image transfer

- Durability: Rust-resistant and waterproof

- Lightweight: Easy to handle and install

- Fireproof and weatherproof: Ideal for indoor and outdoor applications

- Smooth surface: Perfect bonding with sublimation ink

Applications of Aluminum Blanks for Sublimation

Aluminum sublimation panels are used in many fields:

- Photography:

- Custom photo panels

- Art displays

- Signage:

- Indoor signs

- Outdoor nameplates

- Directional signs

- Personalized Gifts:

- Awards and plaques

- Wedding souvenirs

- Pet tags

- Business Branding:

- Company logos

- Promotional items

- Home Decor:

- Wall art

- Family photo panels

How to Use Aluminum Blanks for Sublimation

Using sublimation aluminum blanks is simple:

- Design your image in sublimation software (e.g., CorelDRAW, Photoshop).

- Print the design using a sublimation printer and sublimation ink on transfer paper.

- Place the print face down on the aluminum blank.

- Use a heat press at 180–200°C for 45–60 seconds.

- Remove the paper, and your design is transferred!

Make sure to use proper pressure and protect the surface with heat-resistant tape or sheets.

Frequently Asked Questions

Can I use aluminum sublimation blanks at home?

Yes! Many hobbyists use sublimation blanks at home with small heat press machines and desktop sublimation printers.

Are aluminum sublimation sheets weatherproof?

Yes, they are corrosion-resistant and ideal for both indoor and outdoor use.

What is the best coating for sublimation?

A white polyester coating is the most common and gives the brightest image transfer.

Can I get custom shapes and sizes?

Absolutely. At WORTHWILL ALUMINUM, we offer customized shapes, sizes, and even hole punching and corner rounding.

Choose Us – Trusted Manufacturer in China

Our factory is a leading supplier of aluminum sublimation blanks. We provide:

- High-quality coating for excellent print results

- Custom manufacturing service

- Competitive wholesale pricing

- Fast shipping and excellent customer support

Whether you’re a distributor, workshop, or online shop owner, we can supply the sublimation blanks you need.

Contact Us Today for Your Sublimation Aluminum Blanks

Need a bulk quote or custom specification? Get in touch with our team to explore pricing, samples, and production details.

What Are Aluminum Blanks for Sublimation?

Aluminum blanks for sublimation are sheets of aluminum metal that have been treated with a special polyester coating. This coating is the key to the sublimation process. When sublimation ink is heated and pressed onto these blanks, the ink turns into a gas and bonds permanently with the polyester coating. Unlike traditional printing on metal, where ink sits on the surface, with sublimation aluminum, the image becomes part of the coating itself. This creates a remarkably durable, scratch-resistant, and waterproof finish that won’t fade, peel, or crack. They are truly a premium choice for displaying images.

Why Choose Aluminum Blanks for Sublimation?

Choosing aluminum blanks for sublimation offers several distinct advantages over other materials:

- Exceptional Vibrancy: Sublimated images on aluminum are incredibly vivid with rich colors and sharp details, often appearing almost three-dimensional.

- Durability: They are highly resistant to scratches, moisture, and UV fading, making them suitable for both indoor and certain outdoor uses.

- Modern Aesthetic: The sleek, metallic finish of sublimation aluminum gives a contemporary and professional look to any image.

- Lightweight: Despite their strength, aluminum blanks are relatively lightweight, making them easy to hang or display.

- Easy to Clean: A simple wipe with a damp cloth is usually enough to keep them looking pristine.

These benefits make aluminum blanks for sublimation a top choice for photographers, artists, and businesses seeking high-quality, long-lasting displays.

Sublimation Blank 12″ x 18″ Aluminum Photo Panels

One of the most popular and versatile sizes in the world of metal prints is the Sublimation Blank 12″ x 18″ Aluminum Photo Panels. This size strikes a perfect balance, being large enough to make a statement but still manageable for most sublimation setups.

12″ x 18″ aluminum photo panels are ideal for:

- Displaying cherished photographs: Transform family portraits, wedding photos, or scenic landscapes into stunning pieces of art.

- Creating custom wall art: Design unique pieces to match your home or office decor.

- Professional photography prints: Offer clients durable and visually striking prints of their sessions.

- Business signage and displays: Create sleek, durable signs for offices, lobbies, or events.

- Art reproductions: Artists can reproduce their work on a modern medium that enhances color and depth.

These sublimation aluminum panels often come with rounded corners for a finished look and can be easily framed or displayed using various mounting options. They are a fantastic way to turn digital images into tangible works of art with a premium feel.

Lower Cost for Aluminum Sublimation Blanks

While aluminum blanks for sublimation are a premium product, there are ways to manage costs, especially if you’re looking to buy a larger quantity or start a business:

- Buy in Bulk: Suppliers often offer significant discounts when you purchase larger quantities of sublimation aluminum. If you know you’ll be using many, this is the most effective way to lower the per-unit cost.

- Look for Sales and Promotions: Keep an eye out for seasonal sales, clearance events, or new customer discounts from sublimation supply companies.

- Compare Suppliers: Shop around. Different vendors may have varying price points for the same quality of aluminum blanks for sublimation.

- Consider Starter Kits: Some suppliers offer kits that include a selection of sublimation blanks, which can sometimes be more cost-effective than buying items individually.

- Standard Sizes: Standard sizes like the 12″ x 18″ aluminum photo panels are often more readily available and thus potentially cheaper than custom-cut sizes.

- Fewer Finishes: Sometimes, opting for the most common finishes (like glossy white) might be slightly more affordable than specialty finishes (like brushed aluminum).

By being strategic in your purchasing, you can make aluminum blanks for sublimation a cost-effective choice for your projects.

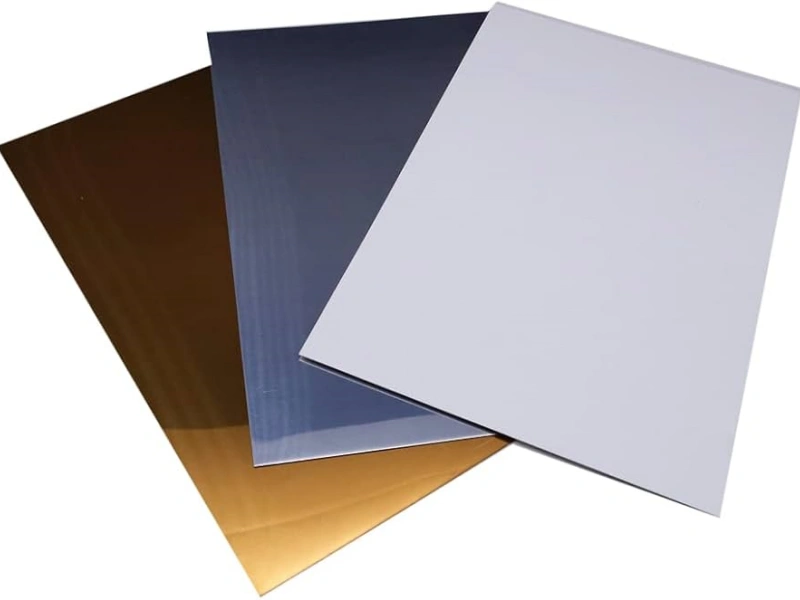

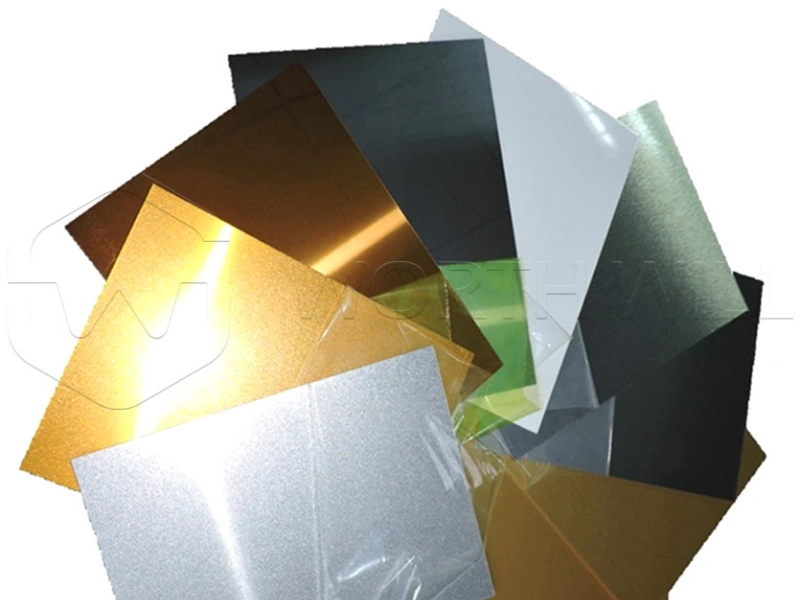

Types of Aluminum Sublimation Blanks

Beyond the standard aluminum photo panels, sublimation aluminum comes in various forms and finishes to suit different creative needs:

- Shapes:

- Rectangular and Square Panels (most common)

- Circles, Ovals

- Heart shapes, Star shapes

- Custom-cut shapes (for specialized projects)

- Finishes:

- Glossy White: The most popular, offering vibrant colors and a high-shine finish.

- Matte White: Provides a non-reflective surface, ideal for minimizing glare, often giving a softer look.

- Brushed Aluminum: Features a subtle brushed texture, allowing some of the metallic sheen to show through the lighter areas of your design.

- Silver/Gold: Transparent coating that lets the natural metallic color of the aluminum enhance the image, creating a metallic effect.

- Sparkle/Glitter: Infused with glitter particles for a unique, eye-catching effect.

- Products:

- Desk Name Plates

- Coasters

- Keychains

- Business Cards

- Ornaments

- Bag Tags

The wide array of aluminum blanks for sublimation ensures that you can find the perfect base for almost any design idea.

Applications of Aluminum Blanks for Sublimation

The versatility of sublimation aluminum means it’s used in many fields:

- Photography: Professional photo printing for galleries, homes, and offices.

- Art Reproduction: Artists creating durable and vibrant reproductions of their paintings and digital art.

- Interior Design: Custom wall art, decorative panels, and architectural features.

- Business & Retail: Durable signage, display graphics, promotional products, and awards.

- Personalized Gifts: Unique and memorable gifts for birthdays, anniversaries, and holidays.

- Event & Exhibition Displays: Lightweight and impactful signage for trade shows and events.

- Museums & Galleries: High-quality archival prints for exhibitions.

- Home Decor: Custom backsplashes, table tops, or decorative tiles.

How to Sublimate on Aluminum Blanks

The process of sublimating on aluminum blanks for sublimation is straightforward:

- Design: Create your image using graphic design software. Ensure it’s mirrored (flipped horizontally) if it contains text or directional elements.

- Print: Print your design onto special sublimation paper using a sublimation printer.

- Prepare the Blank: Ensure your sublimation aluminum blank is clean and free of dust or fingerprints.

- Heat Press: Place the sublimation paper (printed side down) onto the blank. Secure it with heat-resistant tape to prevent ghosting.

- Press: Use a flat heat press at the recommended temperature (usually around 385-400°F or 195-205°C) and pressure for the specified time (typically 45-60 seconds). Consult your blank supplier’s instructions.

- Cool & Reveal: Carefully remove the blank from the heat press. Let it cool slightly before peeling off the sublimation paper to reveal your vibrant image.

Tips for Successful Sublimation on Aluminum

To achieve the best results with your aluminum blanks for sublimation:

- Cleanliness is Key: Even a tiny dust particle can create a blemish on your finished print. Use a lint-free cloth and air blower.

- Proper Protection: Always use protective paper (like butcher paper) above and below your blank in the heat press to prevent ink transfer onto your heat press platens.

- Correct Settings: Temperature, time, and pressure are crucial. Always follow the specific instructions from your sublimation blank supplier.

- Mirror Your Image: This is a common mistake for beginners. Always remember to mirror your design before printing!

- Ventilation: Ensure good ventilation when working with a heat press.

- Handle with Care: Once sublimated, allow the sublimation aluminum to cool completely before handling too much, as it will be very hot.

Finding Quality Aluminum Blanks

When purchasing aluminum blanks for sublimation, prioritize quality. Look for suppliers known for consistent coating and reliable performance. Reading reviews and asking for recommendations from other sublimators can help you find the best sources for your sublimation aluminum needs. Many reputable online sublimation suppliers offer a wide range of sizes and finishes, including the popular 12″ x 18″ aluminum photo panels.