Welcome to the world of aluminum sublimation, UV printing, and engraving on metal. These modern techniques allow you to create beautiful, permanent images and designs on special aluminum sheets. Whether you’re making photo panels, signs, or decorative items, using the right sublimation aluminum sheet or engraving aluminum sheet is key to getting great results.

At HENAN FASTARRIVER INDUSTRIAL CO.,LTD, we specialize in producing high-quality color coated aluminum sheet products. Our focus is on providing excellent SUBLIMATION ALUMINUM SHEET, UV PRINTING ALUMINUM SHEET, and ENGRAVING ALUMINUM SHEET that meet the needs of professionals and hobbyists alike.

What is Sublimation Aluminum Sheet?

Sublimation aluminum sheet is a specially prepared metal sheet designed to accept dye-sublimation ink. Unlike regular aluminum, these sheets have a special coating on the surface. This coating is the key to the sublimation process. When heated, the special dye-sublimation ink turns into a gas and is absorbed by this coating, becoming a permanent part of the aluminum sheet. This creates vibrant, detailed, and durable images.

Similarly, UV PRINTING ALUMINUM SHEET is treated for direct printing using UV-curable inks, and ENGRAVING ALUMINUM SHEET is prepared for precise and clean engraving.

Quality and Technology Behind Our Aluminum Sheets

We take pride in the quality of our color coated aluminum sheet products. We use high-quality raw materials and technology, including German techniques, for the surface treatment of our SUBLIMATION ALUMINUM SHEET, UV PRINTING ALUMINUM SHEET, and ENGRAVING ALUMINUM SHEET.

This process creates a strong, compact honeycomb oxide film on the surface of the aluminum sheet. This special layer helps the paints or coatings bond very tightly with the aluminum. The result is a finished product with:

- Great gloss

- Excellent adhesion (the print sticks well)

- Good corrosion resistance (it resists rust and damage from the environment)

This attention to detail ensures that your printed or engraved designs will look fantastic and last a long time on our aluminum sheets.

Specifications and Series Available

We offer a wide range of options for our SUBLIMATION ALUMINUM SHEET, UV PRINTING ALUMINUM SHEET, and ENGRAVING ALUMINUM SHEET.

The most common thicknesses for these sheets are:

- 0.25 mm

- 0.35 mm

- 0.45 mm

- 0.65 mm

- 0.8 mm

- 1.0 mm

We can also customize the specification and dimensions to fit your specific project needs.

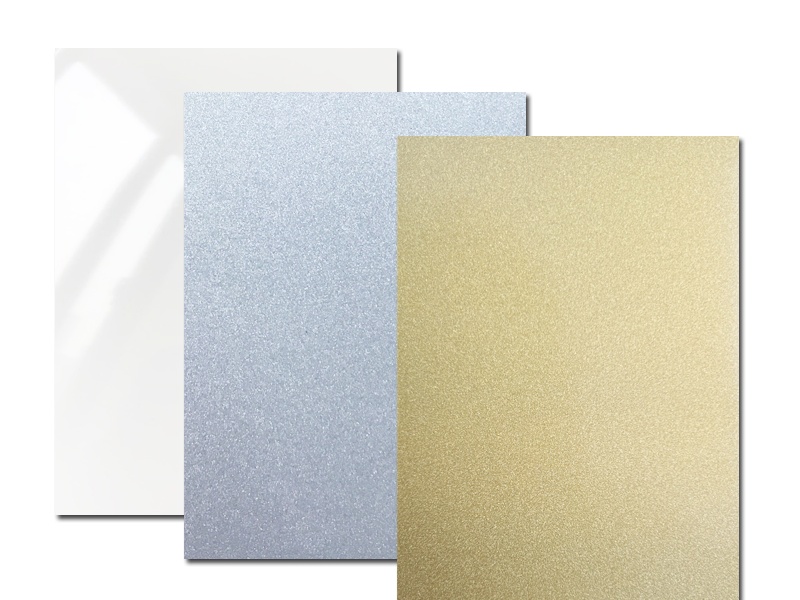

Our color coated aluminum sheets come in various series and colors to give you many creative choices.

Series of Sublimation Aluminum Sheet / UV Printing Aluminum Sheet:

- Pearlized Series:

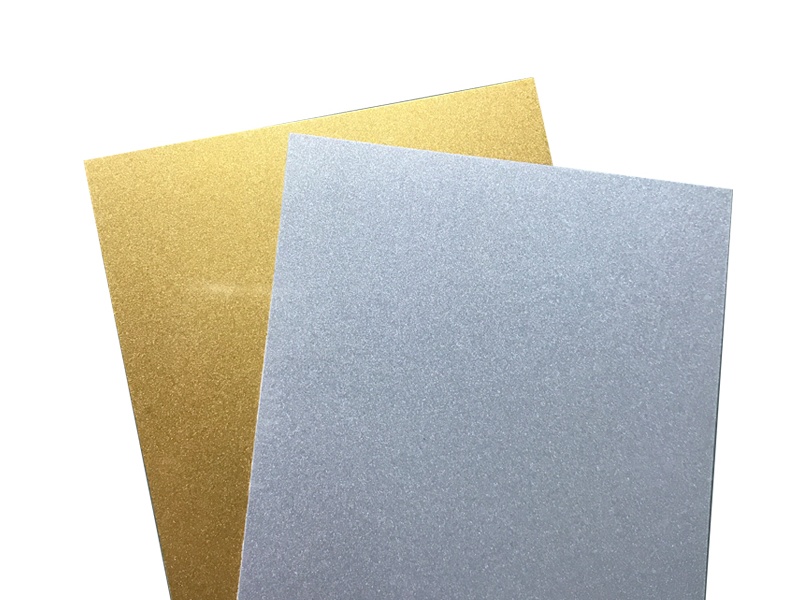

- Pearlized Gold

- Pearlized Silver

- Pearlized White

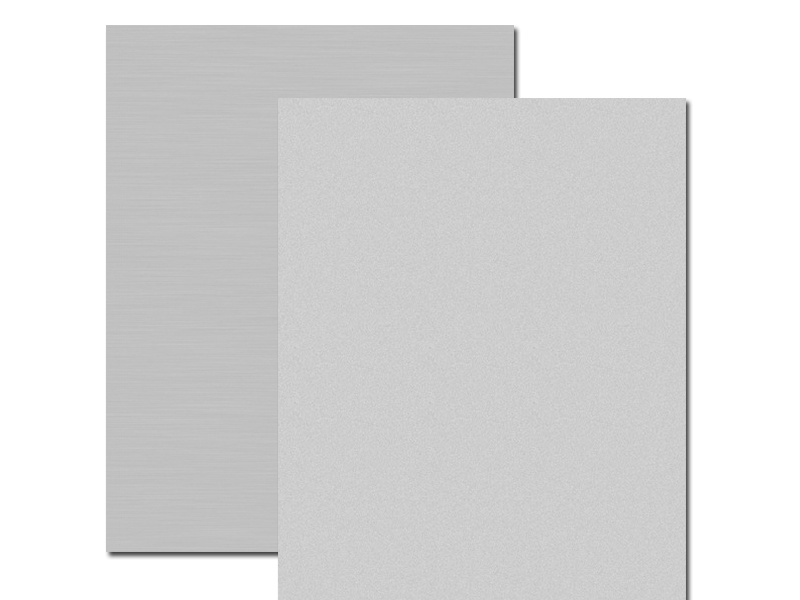

- Brushed Series:

- Brushed Gold

- Brushed Silver

- Brushed Copper (Note: Listed as “Silver Copper”, interpreting as Brushed Copper)

- Satin / Bright Surface Series: (Listed as “亮面”, interpreted as Satin or Bright)

- Satin Gold

- Satin Silver

- Titanium Series:

- Titanium Silver

- Titanium Gold

- White Series:

- High Glossy White

- Matte White

- Mirror Series:

- Mirror Gold

- Mirror Light Gold

- Mirror Silver

These series, including High Glossy, Pearlized, Brushed, Satin, Matte, Mirrored, and Titanium Gold/Silver, are among our hot-sale products, popular for creating stunning sublimation prints and UV printing projects.

Series of Engraving Aluminum Sheet:

- Gloss black

- Gloss red

- Gloss blue

These colored sheets are perfect for engraving, creating a contrast between the engraved design and the base color.

We are always working to develop new series and colors to meet the evolving needs of our clients in the sublimation, UV printing, and engraving industries.

Popular Applications and Products

Our sublimation aluminum sheets and related products are used to create a variety of popular items. The durable and vibrant results make them ideal for many applications.

Here are some examples of what you can make:

- Sublimation Aluminum Photo Panels: Printing cherished photos onto glossy or matte aluminum for a modern, high-definition display.

- Sublimation Aluminum Blanks: Ready-to-print shapes and sizes used for various projects.

- Dye Sublimation onto Aluminum: The process of transferring full-color images onto the treated aluminum surface.

- Sublimation Blank Brushed Silver Aluminum Sheets: Using sheets with a brushed texture for a unique look in sublimation.

- Signs and Displays: Creating durable indoor and outdoor signage.

- Awards and Trophies: Personalizing metal awards.

- Decorative Items: Making coasters, ornaments, and other personalized gifts.

- Industrial Labels: Durable labels for machinery and equipment.

Using a high-quality sublimation blank like our aluminum sheets is essential for achieving professional-looking results. Products like the “10”x12″ High Gloss White Aluminum Sublimation Blank” are examples of standard sizes and finishes ready for your designs.

Answering Your Questions About Aluminum Sublimation

We often get questions about the sublimation process on aluminium. Here are answers to some common ones:

Can you do sublimation on aluminum?

Yes, you absolutely can do sublimation on aluminium, but only if the aluminum sheet has a special polyester coating designed for sublimation. Regular aluminium or aluminum foil will not work because they do not have this coating to absorb the sublimation ink. Our SUBLIMATION ALUMINUM SHEET products are specifically prepared for this process.

What temperature do you sublimate aluminum?

The temperature required for sublimating aluminum typically ranges from 385°F to 400°F (about 195°C to 205°C). The exact temperature can vary slightly depending on the specific type and thickness of the aluminum sheet, the heat press being used, and the desired result. It’s always best to follow the recommendations for your specific sublimation aluminum blank and heat press.

What heat press setting for aluminium sublimation?

Using a heat press is essential for aluminum sublimation. Typical settings involve:

- Temperature: 385°F – 400°F (195°C – 205°C)

- Time: 45 seconds to 90 seconds. Thicker sheets may need slightly longer.

- Pressure: Medium to firm pressure.

It is crucial to do a few test presses on scrap pieces of the same aluminum sheet if possible to find the perfect combination of time, temperature, and pressure for your specific setup and desired outcome. Always place protective paper between the aluminum and the heat press platens.

Can you use aluminum foil for sublimation?

No, you cannot use standard aluminum foil for sublimation. As mentioned earlier, sublimation requires a special polymer coating to absorb the ink gases. Aluminum foil, like the kind used in kitchens, does not have this coating. Attempting to sublimate onto aluminum foil will not transfer the image properly and could potentially damage your heat press. You must use a dedicated sublimation aluminium blank.

Why Choose Our Aluminium Sheets?

Choosing the right materials is vital for any printing or engraving project. Our commitment to quality means you get reliable, consistent results every time you use our SUBLIMATION ALUMINIUM SHEET, UV PRINTING ALUMINIUM SHEET, or ENGRAVING ALUMINIUM SHEET.

FOR US, QUALITY IS OUR CULTURE.

WITH US, YOUR MONEY WILL BE SAFE, YOUR BUSINESS WILL BE SAFE.

We are HENAN FASTARRIVER INDUSTRIAL CO.,LTD, located in the Gongyi Industrial Cluster, Zhengzhou City, Henan Province, China. We are dedicated to providing high-performance color coated aluminum sheet products for sublimation, UV printing, and engraving applications worldwide.

We are confident that our range of finishes, colors, and thicknesses, combined with our focus on quality manufacturing using advanced technology, will help you create outstanding finished products.

If you are looking for reliable, high-quality aluminium sheets for your next sublimation, UV printing, or engraving project, look no further. Explore our series, including High Glossy, Pearlized, Brushed, Satin, Matte, Mirrored, and Titanium, and discover the difference that quality makes. We are ready to help you find the perfect sublimation aluminium blank or engraving aluminium sheet for your needs.